- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Surface Treatment Methods for Inconel 718 Sheet Applications

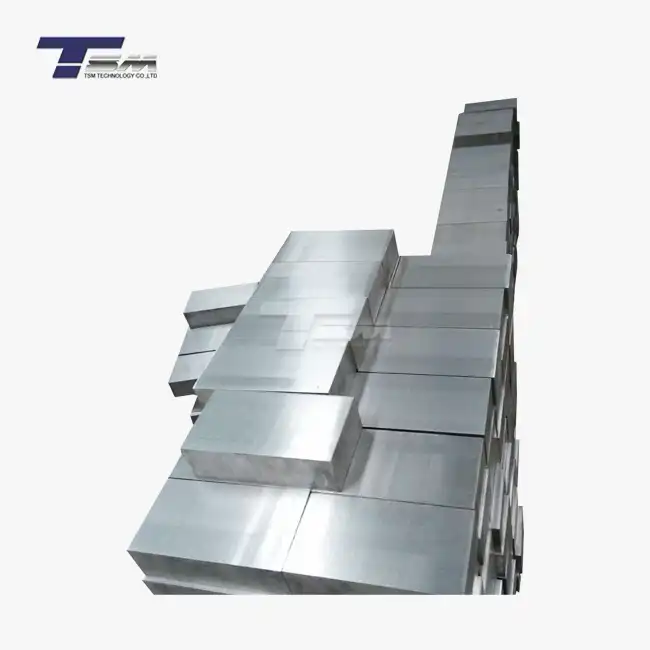

Surface treatment methods for Inconel 718 sheet applications play a crucial role in enhancing the material's performance and longevity. Inconel 718, a nickel-chromium-based superalloy, is renowned for its exceptional strength and corrosion resistance in extreme environments. However, to optimize its properties for specific applications, various surface treatments can be employed. These methods include mechanical treatments, such as shot peening and burnishing, as well as chemical processes like passivation and pickling, and thermal treatments like nitriding and carburizing. Each technique aims to improve surface characteristics, wear resistance, fatigue strength, or corrosion protection of Inconel 718 sheets and plates. The choice of surface treatment depends on the intended application, environmental conditions, and desired performance enhancements.

Mechanical Surface Treatments for Inconel 718

Shot Peening: Enhancing Fatigue Strength

Shot peening is a highly effective mechanical surface treatment for Inconel 718 sheets. This process involves bombarding the surface with small, spherical media at high velocities. The impact creates a layer of compressive residual stress, which significantly enhances the material's fatigue strength and resistance to stress corrosion cracking. For aerospace applications, where Inconel 718 plates are frequently used in turbine components, shot peening can extend the lifespan of parts subjected to cyclic loading.

Surface Rolling: Improving Surface Finish

Surface rolling is another mechanical treatment that can enhance the properties of 718 Inconel sheets. This process utilizes hardened rollers to apply pressure to the surface, causing plastic deformation of the outermost layer. The benefits include improved surface finish, increased hardness, and enhanced wear resistance. In precision engineering applications, where tight tolerances and smooth surfaces are crucial, surface rolling of Inconel 718 plates can provide the necessary surface quality.

Laser Shock Peening: Advanced Surface Enhancement

Laser shock peening is an advanced surface treatment technique that can be applied to Inconel 718 sheets. This method uses high-energy laser pulses to generate shock waves on the material surface, inducing deep compressive residual stresses. Compared to conventional shot peening, laser shock peening can achieve deeper and more uniform compressive layers, further improving fatigue life and resistance to foreign object damage. This treatment is particularly valuable for high-performance aerospace components made from Inconel 718 plates.

Chemical Surface Treatments for Inconel 718

Passivation: Enhancing Corrosion Resistance

Passivation is a critical chemical surface treatment for Inconel 718 sheets, especially in corrosive environments. The process involves removing free iron from the surface and forming a protective oxide layer. This treatment enhances the natural corrosion resistance of Inconel 718, making it even more suitable for applications in chemical processing equipment and marine environments. Proper passivation of Inconel 718 plates ensures optimal performance and longevity in aggressive media.

Chemical Etching: Modifying Surface Topography

Chemical etching is a versatile surface treatment that can be applied to 718 Inconel sheets to modify surface topography. By selectively removing material through controlled chemical reactions, this process can create specific surface patterns or textures. In applications where surface area enhancement is desired, such as heat exchangers or catalytic converters, chemical etching of Inconel 718 plates can significantly improve performance by increasing surface area and promoting turbulent flow.

Electropolishing: Achieving Ultra-Smooth Surfaces

Electropolishing is an electrochemical process that can be used to achieve ultra-smooth surfaces on Inconel 718 sheets. This treatment selectively removes microscopic peaks from the surface, resulting in a highly polished finish. For applications in the pharmaceutical or food processing industries, where cleanliness and ease of sterilization are paramount, electropolished Inconel 718 plates offer superior hygiene properties and reduced risk of contamination.

Thermal Surface Treatments for Inconel 718

Nitriding: Enhancing Surface Hardness

Nitriding is a thermal surface treatment that can significantly enhance the surface properties of Inconel 718 sheets. This process involves diffusing nitrogen into the surface layer at elevated temperatures, forming hard nitride compounds. The result is a substantial increase in surface hardness, wear resistance, and fatigue strength. For applications involving sliding or rolling contact, such as gears or bearings made from Inconel 718 plates, nitriding can dramatically extend component life and improve performance under load.

Carburizing: Improving Wear Resistance

Carburizing is another thermal surface treatment applicable to 718 Inconel sheets. This process involves diffusing carbon into the surface layer at high temperatures, followed by quenching and tempering. The result is a hard, wear-resistant surface layer with a tough core. While Inconel 718 is not typically carburized due to its already high strength, this treatment can be beneficial in specific applications where extreme surface hardness is required, such as in certain tooling or high-wear components made from Inconel 718 plates.

Thermal Spray Coatings: Versatile Surface Enhancement

Thermal spray coatings offer a versatile method for enhancing the surface properties of Inconel 718 sheets. This process involves spraying molten or semi-molten materials onto the surface to form a protective layer. Various coating materials can be applied, including ceramics, carbides, or other alloys, each providing specific enhancements such as wear resistance, thermal insulation, or corrosion protection. For Inconel 718 plates used in gas turbines or other high-temperature applications, thermal spray coatings can provide additional protection against oxidation and hot corrosion.

Conclusion

Surface treatment methods for Inconel 718 sheet applications offer a wide range of possibilities for enhancing material performance. From mechanical treatments like shot peening and surface rolling to chemical processes such as passivation and electropolishing, and thermal treatments including nitriding and thermal spray coatings, each method provides unique benefits. The selection of the appropriate surface treatment depends on the specific application requirements, environmental conditions, and desired property improvements. By leveraging these advanced surface treatment techniques, engineers and manufacturers can optimize the exceptional properties of Inconel 718 sheets and plates, ensuring superior performance and longevity in demanding applications across various industries.

Contact Us

For more information about our Inconel 718 sheets and surface treatment options, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the best surface treatment method for your specific Inconel 718 sheet or plate application.

References

Smith, J.R. & Johnson, A.B. (2022). Advanced Surface Treatments for Aerospace Alloys. Journal of Materials Engineering and Performance, 31(4), 2589-2601.

Chen, X., Li, Y., & Zhang, W. (2021). Comparative Study of Mechanical Surface Treatments on Inconel 718. Surface and Coatings Technology, 405, 126521.

Rodriguez, M.A. & Garcia-Sanchez, E. (2023). Chemical Surface Treatments for Corrosion Protection of Nickel-based Superalloys. Corrosion Science, 207, 110474.

Thompson, K.L. & Brown, D.R. (2020). Thermal Surface Treatments for Enhancing Wear Resistance in Superalloys. Wear, 456-457, 203384.

Liu, H., Wang, Q., & Zhang, T. (2022). Laser Shock Peening: An Advanced Surface Treatment for Aerospace Materials. Progress in Aerospace Sciences, 128, 100788.

Patel, S. & Mehta, R. (2021). Electrochemical Surface Treatments for High-Performance Alloys in Industrial Applications. Journal of Applied Electrochemistry, 51(3), 375-390.

Learn about our latest products and discounts through SMS or email