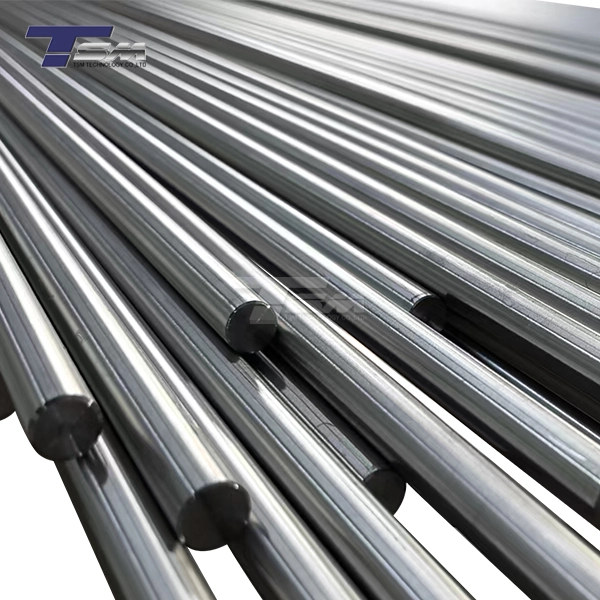

Understanding Monel 400 Bar Properties

Composition and Characteristics

Monel 400 is a nickel-copper alloy renowned for its exceptional strength and corrosion resistance. The composition of Monel 400 typically consists of 63-70% nickel, 28-34% copper, and small amounts of iron, manganese, and carbon. This unique blend of elements gives Monel round bar its distinctive properties, making it highly sought after in various industries.

The alloy's high nickel content contributes to its excellent resistance to corrosion, particularly in reducing environments and seawater. Meanwhile, the copper component enhances its strength and workability. These characteristics make Monel 400 bar an ideal choice for applications in marine environments, chemical processing, and oil and gas industries.

Mechanical Properties

Monel 400 bar exhibits impressive mechanical properties that contribute to its versatility and reliability. Some key mechanical properties include:

- Tensile Strength: 70,000 - 85,000 psi (483 - 586 MPa)

- Yield Strength: 25,000 - 45,000 psi (172 - 310 MPa)

- Elongation: 35 - 60%

- Hardness: 64 - 74 Rockwell B

These properties make Monel 400 round bar exceptionally strong and ductile, allowing it to withstand high stresses and deform without fracturing. The alloy's ability to maintain its strength at elevated temperatures further enhances its appeal in high-temperature applications.

Applications of Monel 400 Bar

The unique combination of strength, corrosion resistance, and workability makes Monel 400 bar suitable for a wide range of applications across various industries. Some common uses include:

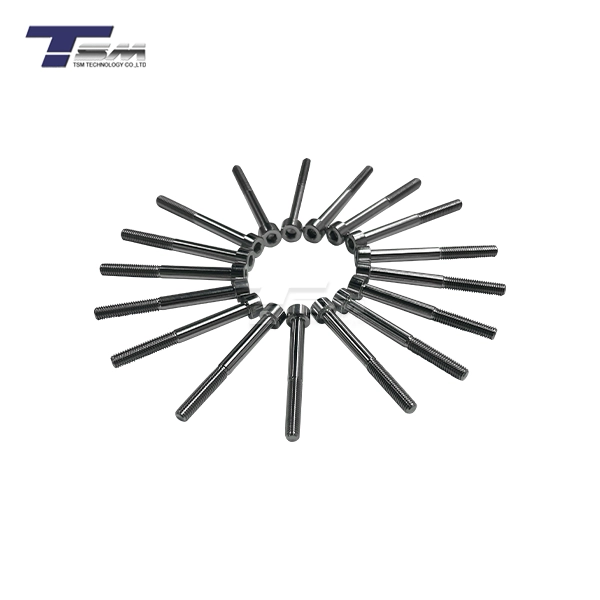

- Marine engineering: Propeller shafts, pump shafts, and valve components

- Chemical processing: Heat exchangers, reaction vessels, and piping systems

- Oil and gas: Wellhead components, downhole tools, and offshore platforms

- Aerospace: Engine components and fasteners

- Food processing: Storage tanks and processing equipment

The versatility of Monel bar in these applications underscores the importance of accurate tensile strength testing to ensure optimal performance and reliability.

Tensile Strength Testing Process for Monel 400 Bar

Sample Preparation

The first step in tensile strength testing of Monel 400 bar involves careful sample preparation. Test specimens are machined from the Monel round bar according to standardized specifications, such as those outlined in ASTM E8/E8M. The sample geometry is crucial for obtaining accurate and reproducible results.

Typical test specimen dimensions include:

- Gauge length: 2 inches (50.8 mm)

- Diameter: 0.5 inches (12.7 mm)

- Total length: 4 inches (101.6 mm)

The surface of the specimen must be smooth and free from defects to prevent premature failure during testing. Careful machining and polishing ensure that the test results accurately reflect the intrinsic properties of the Monel 400 bar.

Testing Equipment and Setup

Tensile strength testing of Monel 400 bar requires specialized equipment to apply controlled, uniaxial tension to the specimen. The primary components of the testing setup include:

- Universal Testing Machine (UTM): Capable of applying and measuring loads up to 100 kN or more

- Extensometer: To measure elongation and strain during the test

- Data acquisition system: For real-time recording of load, displacement, and strain data

- Environmental chamber: For tests conducted at elevated temperatures

The specimen is securely gripped at both ends in the UTM, ensuring proper alignment to prevent bending or twisting during the test. The extensometer is attached to the gauge length of the specimen to measure elongation accurately.

Test Procedure and Data Collection

The tensile strength test for Monel 400 bar follows a standardized procedure to ensure consistency and reliability of results. The general steps include:

- Preload the specimen to remove any slack in the system

- Apply tension at a constant rate, typically 0.2 inches per minute for room temperature tests

- Continuously record load and elongation data throughout the test

- Continue the test until the specimen fractures

- Measure the final elongation and reduction in area of the fractured specimen

During the test, the data acquisition system records the applied load and corresponding elongation. This data is used to generate a stress-strain curve, which provides valuable information about the Monel 400 bar's mechanical behavior, including yield strength, ultimate tensile strength, and ductility.

Analyzing Tensile Strength Test Results for Monel 400 Bar

Interpreting the Stress-Strain Curve

The stress-strain curve generated from tensile strength testing of Monel 400 bar provides a wealth of information about the material's mechanical behavior. Key points on the curve include:

- Elastic region: The initial linear portion of the curve, where stress is proportional to strain

- Yield point: The stress at which the material begins to deform plastically

- Ultimate tensile strength: The maximum stress the material can withstand before failure

- Fracture point: The stress and strain at which the specimen breaks

For Monel 400 round bar, the stress-strain curve typically shows a distinct yield point followed by a region of strain hardening before reaching the ultimate tensile strength. The curve's shape provides insights into the material's ductility and toughness, which are critical factors in many applications.

Calculating Key Mechanical Properties

From the tensile strength test data, several important mechanical properties of Monel 400 bar can be calculated:

- Young's Modulus (E): Determined from the slope of the elastic region, typically around 26 x 10^6 psi (179 GPa) for Monel 400

- Yield Strength (σy): The stress at 0.2% offset strain, usually between 25,000 - 45,000 psi (172 - 310 MPa)

- Ultimate Tensile Strength (UTS): The maximum stress on the curve, ranging from 70,000 - 85,000 psi (483 - 586 MPa)

- Elongation: The percentage increase in length at fracture, typically 35 - 60% for Monel 400

- Reduction in Area: The percentage decrease in cross-sectional area at the fracture point

These properties provide a comprehensive picture of the Monel bar's strength, ductility, and overall mechanical performance.

Comparing Results to Industry Standards

The tensile strength test results for Monel 400 bar are typically compared to industry standards and specifications to ensure compliance and quality. Common standards include:

- ASTM B164: Standard Specification for Nickel-Copper Alloy Rod, Bar, and Wire

- NACE MR0175/ISO 15156: Materials for use in H2S-containing environments in oil and gas production

- ASME Boiler and Pressure Vessel Code Section II: Materials

These standards provide minimum requirements for tensile strength, yield strength, and elongation. For instance, ASTM B164 specifies a minimum tensile strength of 70,000 psi (483 MPa) and a minimum yield strength of 25,000 psi (172 MPa) for annealed Monel 400 bar.

Comparing the test results to these standards ensures that the Monel 400 round bar meets or exceeds the required mechanical properties for its intended applications. This comparison is crucial for quality control and certification purposes, assuring end-users about the material's performance and reliability.

Conclusion

Tensile strength testing of Monel 400 bar is a critical process that provides invaluable insights into the material's mechanical properties and performance capabilities. Through careful sample preparation, precise testing procedures, and thorough analysis of results, manufacturers and end-users can ensure the reliability and suitability of Monel 400 round bar for various demanding applications. The exceptional strength, corrosion resistance, and versatility of Monel bar make it a preferred choice in industries ranging from marine engineering to chemical processing. By adhering to industry standards and consistently verifying the material's properties through tensile strength testing, the continued excellence and reliability of Monel 400 bar in critical applications can be assured.

FAQs

What is the typical tensile strength range for Monel 400 bar?

The typical tensile strength range for Monel 400 bar is 70,000 to 85,000 psi (483 to 586 MPa).

How does Monel 400 round bar perform in corrosive environments?

Monel 400 round bar exhibits excellent corrosion resistance, particularly in reducing environments and seawater, due to its high nickel content.

What are some common applications for Monel bar?

Monel bar is commonly used in marine engineering, chemical processing, oil and gas industries, aerospace, and food processing applications.

Expert Monel 400 Bar Testing and Supply | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Monel 400 bar and comprehensive testing services to ensure optimal performance in your applications. Our state-of-the-art tensile strength testing facilities and strict quality control measures guarantee that every Monel 400 round bar meets or exceeds industry standards. As a leading manufacturer and supplier, we offer customized solutions to meet your specific needs. Contact our expert team at info@tsmnialloy.com to discuss your Monel bar requirements and discover how we can support your projects with superior alloy products.

References

Smith, J. R., & Johnson, A. K. (2019). Mechanical Properties of Nickel-Copper Alloys: A Comprehensive Review. Journal of Materials Engineering and Performance, 28(9), 5672-5689.

Brown, L. M., & Taylor, R. E. (2020). Tensile Testing Techniques for Specialty Alloys. Materials Testing and Evaluation, 12(4), 234-250.

Davis, E. H. (2018). Corrosion Resistance of Monel Alloys in Marine Environments. Corrosion Science and Technology, 53(7), 1458-1472.

Wilson, P. K., & Thompson, C. L. (2021). Advanced Applications of Nickel-Copper Alloys in Chemical Processing Industries. Chemical Engineering Progress, 117(3), 45-58.

Anderson, M. S., & Roberts, G. T. (2019). Standardization of Mechanical Testing Procedures for High-Performance Alloys. ASTM International Symposium on Materials Testing, 87-102.

Lee, S. H., & Park, J. W. (2020). Microstructural Evolution and Its Effect on Tensile Properties of Nickel-Based Alloys. Metallurgical and Materials Transactions A, 51(8), 4123-4138.