- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Tensile Testing Techniques for Incoloy 825 Tubes

Tensile testing techniques for Incoloy 825 tubes are crucial for evaluating the mechanical properties and performance of this high-performance nickel-iron-chromium alloy. These tests assess the material's strength, ductility, and overall quality, ensuring its suitability for various demanding applications. The process involves subjecting Incoloy 825 tube specimens to controlled axial forces, measuring their stress response, and analyzing key parameters such as yield strength, ultimate tensile strength, and elongation. Proper testing procedures are essential for obtaining accurate results, which guide material selection, quality control, and design considerations in industries ranging from chemical processing to oil and gas exploration.

Understanding Incoloy 825 and Its Properties

Composition and Characteristics of Incoloy 825

Incoloy 825 is a versatile nickel-iron-chromium alloy known for its exceptional corrosion resistance and mechanical strength. Its composition typically includes 38-46% nickel, 19.5-23.5% chromium, 2.5-3.5% molybdenum, and small amounts of copper and titanium. This unique blend of elements contributes to the alloy's outstanding resistance to various corrosive environments, including sulfuric and phosphoric acids, as well as stress-corrosion cracking in chloride-ion environments.

Applications of Incoloy 825 Tubes

Incoloy 825 tubes find extensive use in industries where corrosion resistance and high-temperature strength are paramount. Common applications include heat exchangers, chemical processing equipment, nuclear fuel reprocessing plants, and offshore oil and gas production systems. The alloy's ability to withstand aggressive media and maintain its properties at elevated temperatures makes it an ideal choice for these demanding environments.

Importance of Tensile Testing for Incoloy 825 Pipes

Tensile testing plays a critical role in validating the mechanical properties of Incoloy 825 pipes. It helps ensure that the material meets the required specifications and can withstand the operational stresses in its intended applications. By subjecting the alloy to controlled tensile forces, manufacturers and end-users can assess its strength, ductility, and overall quality, providing crucial data for design, quality control, and safety considerations.

Tensile Testing Methodologies for Incoloy 825 Tubes

Specimen Preparation and Standards

Proper specimen preparation is essential for accurate tensile testing of Incoloy 825 tubes. The test specimens are typically machined from the tube wall, ensuring that they represent the material's properties accurately. The preparation process follows strict standards, such as ASTM E8/E8M or ISO 6892-1, which specify dimensions, surface finish, and orientation of the test specimens. For Incoloy 825 pipe samples, care must be taken to account for any potential anisotropy resulting from the manufacturing process.

Testing Equipment and Setup

Tensile testing of Incoloy 825 tubes requires specialized equipment capable of applying controlled axial loads and accurately measuring the material's response. Modern universal testing machines equipped with precise load cells and extensometers are commonly used. The setup often includes environmental chambers for tests at elevated temperatures, simulating the operational conditions of Incoloy 825 pipes in high-temperature applications. Proper alignment of the specimen and grips is crucial to avoid introducing bending stresses that could skew the results.

Test Procedures and Data Collection

The tensile test procedure for Incoloy 825 tubes typically involves applying a gradually increasing axial load to the specimen until failure occurs. Throughout the test, the applied force and the corresponding elongation of the specimen are continuously monitored and recorded. Key data points, such as yield strength, ultimate tensile strength, and elongation at break, are determined from the stress-strain curve generated during the test. For Incoloy 825 pipe samples, additional considerations may include assessing the anisotropy between longitudinal and transverse directions.

Analysis and Interpretation of Tensile Test Results

Key Parameters and Their Significance

The analysis of tensile test results for Incoloy 825 tubes focuses on several key parameters. Yield strength indicates the stress at which the material begins to deform plastically, crucial for designing components within safe operational limits. Ultimate tensile strength represents the maximum stress the material can withstand before failure, providing insights into its load-bearing capacity. Elongation at break measures the material's ductility, an important factor in assessing its formability and resistance to brittle fracture. For Incoloy 825 pipe applications, these parameters help engineers determine the material's suitability for specific operational conditions.

Comparison with Industry Standards

Tensile test results for Incoloy 825 tubes are typically compared against industry standards and specifications to ensure compliance. Organizations such as ASTM International and ASME provide minimum requirements for mechanical properties, including yield strength, tensile strength, and elongation. For instance, ASTM B423, which covers nickel-iron-chromium-molybdenum-copper alloy (UNS N08825) seamless pipe and tube, specifies minimum yield strength of 25 ksi (172 MPa) and minimum tensile strength of 65 ksi (448 MPa) for annealed material. Comparing test results with these standards helps validate the quality and performance of Incoloy 825 pipes.

Identifying Material Defects and Quality Issues

Tensile testing can reveal potential defects or quality issues in Incoloy 825 tubes. Abnormalities in the stress-strain curve, such as premature yielding or unexpected brittleness, may indicate problems with the material's composition, heat treatment, or manufacturing process. For Incoloy 825 pipe products, variations in properties between different batches or along the length of a tube can be identified through systematic testing. This information is invaluable for quality control, allowing manufacturers to address issues promptly and ensure consistent product performance.

Conclusion

Tensile testing techniques for Incoloy 825 tubes are indispensable tools in ensuring the reliability and performance of this high-performance alloy in critical applications. By carefully preparing specimens, conducting standardized tests, and analyzing the results, manufacturers and end-users can validate the mechanical properties of Incoloy 825 pipes and tubes. This rigorous approach to quality control contributes to the safe and efficient use of Incoloy 825 in challenging environments, from chemical processing plants to offshore oil platforms. As material science advances, continuous refinement of testing methodologies will further enhance our understanding and utilization of this versatile alloy.

FAQs

What is the typical yield strength of Incoloy 825 tubes?

The yield strength of Incoloy 825 tubes typically ranges from 25 to 30 ksi (172 to 207 MPa), depending on the specific grade and heat treatment.

How does temperature affect the tensile properties of Incoloy 825 pipes?

Elevated temperatures can reduce the yield and tensile strength of Incoloy 825 pipes, but the alloy maintains good mechanical properties up to about 1000°F (538°C).

Are there any special considerations for tensile testing Incoloy 825 welded tubes?

Yes, tensile testing of welded Incoloy 825 tubes often includes evaluating both the base metal and the weld zone to ensure overall structural integrity.

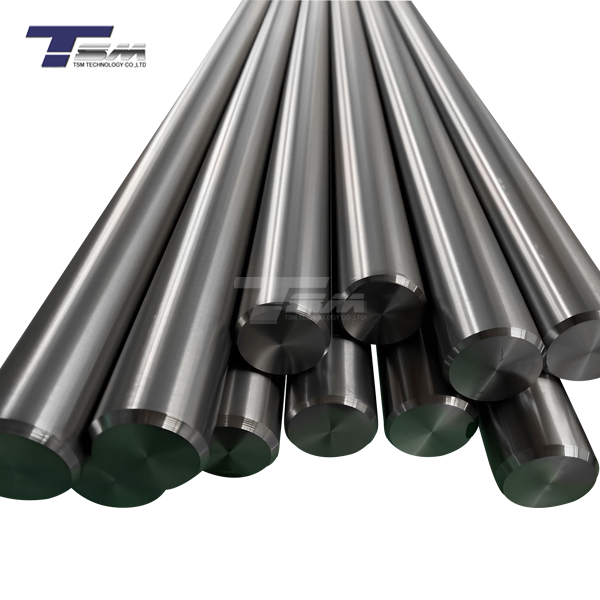

High-Quality Incoloy 825 Tubes for Sale | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in manufacturing and supplying premium Incoloy 825 tubes and pipes. Our state-of-the-art production facilities and strict quality control processes ensure superior durability, performance, and consistency across all products. Whether you require standard sizes or custom specifications, our expert team is ready to provide tailored solutions to meet your needs. Contact our factory at info@tsmnialloy.com to learn more about our high-quality Incoloy 825 tubes and place your order today.

References

ASTM International. (2020). ASTM E8/E8M-21: Standard Test Methods for Tension Testing of Metallic Materials. West Conshohocken, PA: ASTM International.

Special Metals Corporation. (2018). Incoloy alloy 825 Technical Data Sheet. Huntington, WV: Special Metals Corporation.

ASM International. (2019). ASM Handbook, Volume 8: Mechanical Testing and Evaluation. Materials Park, OH: ASM International.

Mankins, W. L., & Lamb, S. (1990). Nickel and nickel alloys. In Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, ASM Handbook (Vol. 2, pp. 428-445). Materials Park, OH: ASM International.

ISO. (2019). ISO 6892-1:2019 Metallic materials - Tensile testing - Part 1: Method of test at room temperature. Geneva: International Organization for Standardization.

NACE International. (2017). NACE MR0175/ISO 15156: Materials for use in H2S-containing environments in oil and gas production. Houston, TX: NACE International.

Learn about our latest products and discounts through SMS or email