- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

The Properties and Advantages of Nickel Alloy Sheet

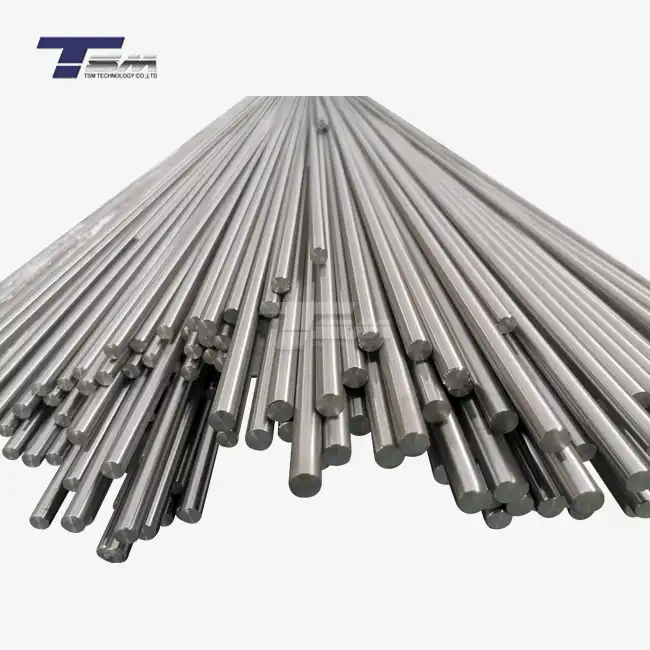

Nickel alloy sheets are engineered materials that combine exceptional strength, corrosion resistance, and high-temperature performance. These versatile metal products are crafted from nickel-based alloys, offering superior properties that make them indispensable in various industries. From aerospace to chemical processing, nickel alloy sheets provide unparalleled durability and reliability in extreme environments. Their unique composition allows them to maintain structural integrity under intense heat, resist oxidation and corrosion, and offer excellent fabricability. As demand for high-performance materials continues to grow, nickel alloy sheets remain at the forefront of engineering solutions, enabling technological advancements and ensuring operational efficiency in critical applications worldwide.

Composition and Manufacturing of Nickel Alloy Sheets

Alloy Composition and Types

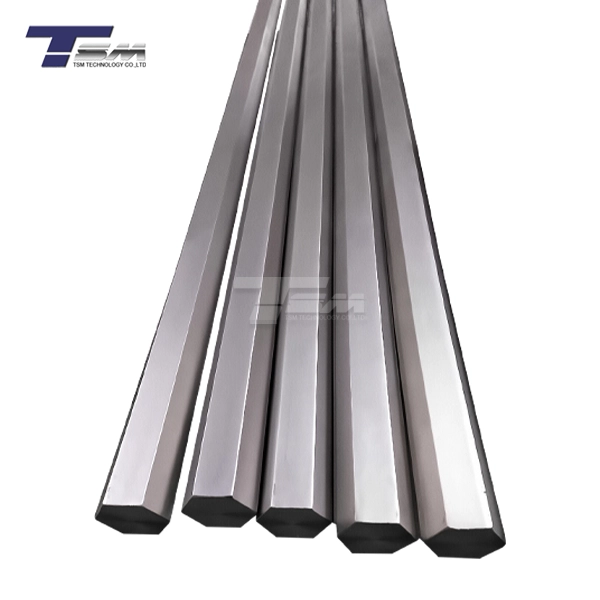

Nickel alloy sheets are crafted from a diverse range of nickel-based materials, each tailored for specific applications. These alloys typically contain a high percentage of nickel combined with other elements such as chromium, molybdenum, and iron. Popular nickel alloy families include Inconel, Hastelloy, Monel, and Incoloy, each offering unique properties. For instance, Inconel alloys excel in high-temperature applications, while Hastelloy variants provide superior corrosion resistance in aggressive chemical environments.

Manufacturing Processes

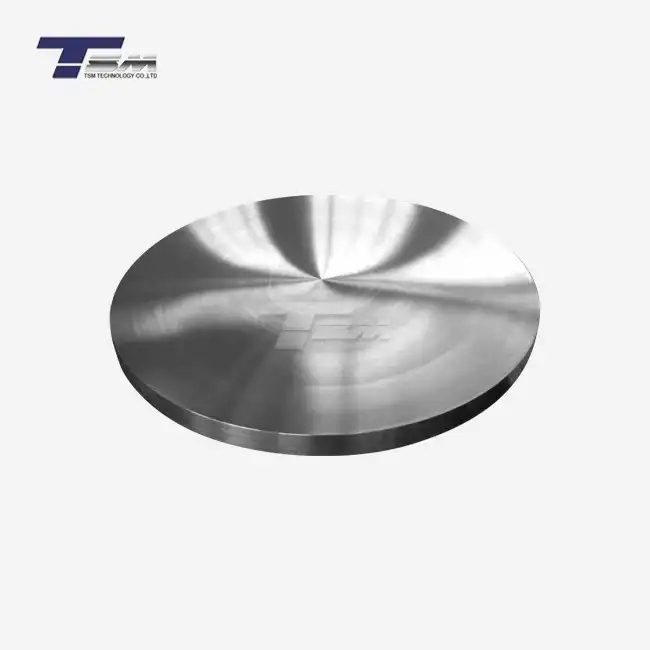

The production of nickel alloy plates involves sophisticated manufacturing techniques. The process begins with melting the alloy components in controlled environments to ensure purity and precise composition. The molten metal is then cast into ingots or continuous cast slabs. These are subsequently hot-rolled to achieve the desired thickness, followed by cold rolling for further thickness reduction and improved surface finish. Heat treatment processes such as solution annealing and stress relieving are applied to enhance the material's properties and relieve internal stresses.

Quality Control Measures

Rigorous quality control is essential in nickel alloy sheet production. Manufacturers employ various testing methods to ensure the integrity and performance of the final product. These include spectral analysis for composition verification, ultrasonic testing for detecting internal flaws, and intergranular corrosion tests like ASTM G28. Each sheet is typically laser-marked with unique identifiers for traceability, allowing manufacturers to track the material from production through to end-use.

Key Properties of Nickel Alloy Sheets

Corrosion Resistance

One of the most remarkable properties of nickel alloy sheets is their exceptional corrosion resistance. These materials can withstand highly aggressive environments, including exposure to acidic, alkaline, and oxidizing substances. The formation of a protective oxide layer on the surface of nickel alloys contributes to their corrosion resistance, making them ideal for use in chemical processing plants, offshore oil and gas facilities, and marine applications where standard materials would rapidly deteriorate.

High-Temperature Performance

Nickel alloy sheets exhibit outstanding strength and stability at elevated temperatures. Unlike many other metals that lose their structural integrity when subjected to high heat, nickel alloys maintain their mechanical properties even at temperatures exceeding 1000°C. This characteristic makes them invaluable in aerospace engines, gas turbines, and industrial furnaces where materials must perform reliably under extreme thermal conditions.

Mechanical Strength and Ductility

The combination of high strength and ductility in nickel alloy sheets sets them apart from other materials. These alloys offer excellent tensile and yield strengths across a wide temperature range, coupled with good elongation properties. This balance allows for the fabrication of complex components that can withstand high stresses and fatigue loads while remaining resistant to cracking and deformation. The mechanical versatility of nickel alloy sheets makes them suitable for both structural applications and parts requiring precise forming.

Advantages and Applications of Nickel Alloy Sheets

Industrial Applications

Nickel alloy sheets find extensive use across various industries due to their unique properties. In the chemical processing sector, they are utilized for constructing reactors, heat exchangers, and piping systems that handle corrosive materials. The aerospace industry relies on nickel alloy sheets for manufacturing turbine blades, exhaust systems, and other critical components exposed to high temperatures and stresses. In the energy sector, these materials play a crucial role in power generation equipment, including gas turbines and nuclear reactors, where reliability and longevity are paramount.

Cost-Effectiveness and Longevity

While the initial cost of nickel alloy plates may be higher compared to some conventional materials, their long-term cost-effectiveness is undeniable. The exceptional durability and resistance to degradation result in extended service life and reduced maintenance requirements. This longevity translates to lower lifecycle costs, fewer replacements, and minimized downtime in industrial operations. Furthermore, the ability of nickel alloy plates to perform in harsh environments often eliminates the need for additional protective measures or frequent part replacements, leading to overall cost savings.

Customization and Fabrication Advantages

Nickel alloy sheets offer excellent fabricability, allowing for a wide range of manufacturing processes. They can be easily welded, machined, and formed into complex shapes without compromising their properties. This versatility enables designers and engineers to create custom solutions for specific applications. Advanced surface treatments, such as pickling and electropolishing, can further enhance the performance characteristics of nickel alloy sheets. The ability to tailor these materials to precise specifications makes them invaluable in industries where standard off-the-shelf solutions are inadequate.

Conclusion

Nickel alloy sheets stand out as exceptional engineering materials, offering a unique combination of corrosion resistance, high-temperature strength, and versatility. Their ability to perform in extreme environments makes them indispensable in critical industries such as aerospace, chemical processing, and energy production. As technology advances and industrial demands become more challenging, the role of nickel alloy sheets in enabling innovation and ensuring operational reliability continues to grow. For businesses and engineers seeking high-performance materials that can withstand the most demanding conditions, nickel alloy sheets provide a robust and dependable solution.

FAQs

What are the main advantages of using nickel alloy sheets?

Nickel alloy sheets offer exceptional corrosion resistance, high-temperature strength, and excellent fabricability. They maintain their properties in extreme environments, making them ideal for aerospace, chemical processing, and energy sectors.

How do nickel alloy sheets compare to stainless steel in terms of corrosion resistance?

While both materials offer good corrosion resistance, nickel alloy sheets generally outperform stainless steel in more aggressive environments, particularly at higher temperatures and in the presence of certain chemicals.

Can nickel alloy sheets be customized for specific applications?

Yes, nickel alloy sheets can be tailored through composition adjustments, heat treatments, and surface finishes to meet specific application requirements, offering a high degree of customization.

Experience the Superior Quality of Nickel Alloy Sheets | TSM TECHNOLOGY

At TSM TECHNOLOGY, we pride ourselves on delivering premium nickel alloy sheets that meet the most stringent industry standards. Our state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every sheet we produce exceeds expectations. With a wide range of alloy options and customization capabilities, we're your trusted partner for high-performance materials. Experience the TSM difference today. For inquiries or to discuss your specific needs, please contact us at info@tsmnialloy.com.

References

Davis, J.R. (2000). Nickel, Cobalt, and Their Alloys. ASM International.

Donachie, M.J., & Donachie, S.J. (2002). Superalloys: A Technical Guide. ASM International.

Special Metals Corporation. (2007). High-Performance Alloys for Resistance to Aqueous Corrosion. Special Metals Corporation Publication Number SMC-026.

Reed, R.C. (2006). The Superalloys: Fundamentals and Applications. Cambridge University Press.

ASTM International. (2015). ASTM B168-15 Standard Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Plate, Sheet, and Strip.

Klarstrom, D.L., Crook, P., & Wu, J.B.C. (2004). Metallurgical Design of Alloys for Corrosion Control. Corrosion: Fundamentals, Testing, and Protection, 13A, ASM Handbook, ASM International.

Learn about our latest products and discounts through SMS or email