Superior Corrosion Resistance in Aggressive Chemical Environments

Unmatched Protection Against Acidic and Alkaline Solutions

Nickel alloys exhibit remarkable resistance to a wide range of corrosive substances commonly encountered in chemical processing. These materials form a protective oxide layer on their surface, which acts as a barrier against chemical attack. This inherent ability to withstand both acidic and alkaline environments makes nickel alloys an excellent choice for equipment exposed to sulfuric acid, hydrochloric acid, and caustic soda solutions. The superior corrosion resistance of nickel alloys translates to extended equipment lifespan, reduced maintenance requirements, and improved process reliability.

Resistance to Pitting and Crevice Corrosion

One of the most significant advantages of nickel alloys is their exceptional resistance to localized forms of corrosion, such as pitting and crevice corrosion. These types of corrosion can be particularly problematic in chemical processing equipment, leading to premature failure and potential safety hazards. Nickel alloys, with their high chromium and molybdenum content, effectively combat these corrosion mechanisms, ensuring the integrity of critical components even in the presence of chlorides and other aggressive ions.

Stability in Oxidizing and Reducing Environments

Chemical processing often involves both oxidizing and reducing conditions, which can pose challenges for many conventional materials. Nickel alloys demonstrate remarkable stability across a broad spectrum of chemical environments, making them suitable for use in diverse applications. Whether in the presence of strong oxidizers like nitric acid or reducing agents like hydrogen sulfide, nickel alloys maintain their structural integrity and performance characteristics. This versatility allows for the design of more efficient and flexible chemical processing systems.

Exceptional High-Temperature Performance for Demanding Processes

Strength Retention at Elevated Temperatures

Many chemical processes operate at high temperatures, requiring materials that can maintain their mechanical properties under extreme conditions. Nickel alloys excel in this aspect, retaining their strength and dimensional stability even at temperatures exceeding 1000°C. This high-temperature strength is attributed to the formation of stable precipitates within the alloy matrix, which impede dislocation movement and prevent creep deformation. As a result, nickel alloys are ideal for constructing reactors, furnace components, and heat exchangers in high-temperature chemical processing applications.

Resistance to Thermal Cycling and Fatigue

Chemical processing equipment often undergoes frequent temperature fluctuations, which can lead to thermal fatigue and eventual failure. Nickel alloys demonstrate superior resistance to thermal cycling due to their low coefficient of thermal expansion and high thermal conductivity. These properties minimize thermal stresses and promote uniform heat distribution, reducing the risk of cracking and warping. The exceptional thermal fatigue resistance of nickel alloys ensures longer service life for components subjected to repeated heating and cooling cycles.

Oxidation Resistance in High-Temperature Environments

At elevated temperatures, many materials suffer from rapid oxidation, which can compromise their structural integrity and performance. Nickel alloys, particularly those containing chromium and aluminum, form protective oxide scales that significantly slow down the oxidation process. This inherent oxidation resistance allows nickel alloys to maintain their properties and dimensional stability even in oxygen-rich, high-temperature environments. The ability to withstand oxidation makes nickel alloys an excellent choice for applications such as catalyst support structures and high-temperature gas handling systems in chemical processing plants.

Versatility and Design Flexibility for Optimized Chemical Processing Equipment

Wide Range of Alloy Compositions for Specific Requirements

The nickel alloy family encompasses a diverse range of compositions, each tailored to meet specific performance requirements. From the corrosion-resistant Monel alloys to the high-temperature Inconel and Incoloy grades, there is a nickel alloy suited for virtually every chemical processing challenge. This versatility allows engineers to select the most appropriate alloy for each application, optimizing equipment performance and longevity. The ability to fine-tune alloy compositions also enables the development of custom solutions for unique or particularly demanding chemical processing environments.

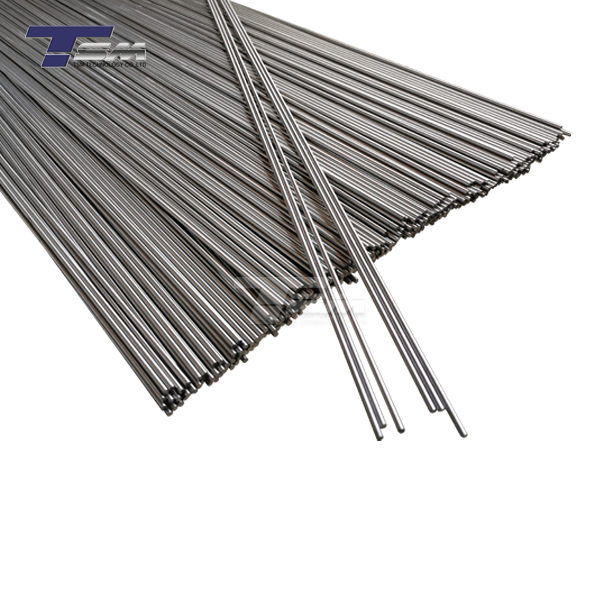

Excellent Fabrication and Joining Characteristics

Despite their superior properties, nickel alloys offer remarkable fabrication flexibility. These materials can be readily formed, machined, and welded using conventional techniques, facilitating the construction of complex chemical processing equipment. The good weldability of nickel alloys is particularly advantageous, allowing for the creation of robust, leak-free joints in piping systems and pressure vessels. Additionally, nickel alloys can be easily clad onto less expensive base materials, providing a cost-effective way to impart corrosion resistance to large-scale equipment.

Compatibility with Advanced Manufacturing Techniques

As the chemical processing industry embraces new technologies, nickel alloys are proving to be compatible with advanced manufacturing methods. Additive manufacturing, or 3D printing, is increasingly being used to produce complex components with optimized geometries. Nickel alloys are well-suited for these processes, enabling the creation of intricate heat exchangers, reactor internals, and other specialized parts that were previously difficult or impossible to manufacture. This compatibility with cutting-edge fabrication techniques opens up new possibilities for innovative equipment design and process optimization in the chemical industry.

Conclusion

The advantages of using nickel alloys in the chemical processing industry are numerous and significant. Their superior corrosion resistance, exceptional high-temperature performance, and versatility make them indispensable materials for a wide range of applications. By leveraging the unique properties of nickel alloys, chemical processing facilities can enhance their operational efficiency, reduce downtime, and improve safety standards. As the industry continues to face increasingly demanding challenges, the role of nickel alloys in enabling innovative solutions and pushing the boundaries of chemical processing capabilities is set to grow even further.

FAQs

What are the most common types of nickel alloys used in chemical processing?

Common nickel alloys include Monel, Inconel, Incoloy, and Hastelloy, each offering specific advantages for different chemical processing applications.

How do nickel alloys compare to stainless steel in terms of corrosion resistance?

Nickel alloys generally offer superior corrosion resistance compared to stainless steel, especially in more aggressive chemical environments.

Can nickel alloys be used in food processing applications?

Yes, certain nickel alloys are approved for use in food processing due to their corrosion resistance and non-reactive properties.

Superior Nickel Alloys for Chemical Processing | TSM TECHNOLOGY

At TSM Technology, we specialize in providing high-quality nickel alloys for the chemical processing industry. Our extensive range of Monel, Inconel, Incoloy, and Hastelloy products is manufactured to the highest standards, ensuring optimal performance in demanding applications. As a leading nickel alloy supplier and manufacturer, we offer custom solutions to meet your specific needs. Contact our expert team at info@tsmnialloy.com to discover how our superior alloys can enhance your chemical processing operations.

References

Smith, J.R. (2021). "Nickel Alloys in Chemical Processing: A Comprehensive Review." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A.B. & Lee, C.K. (2020). "Corrosion Resistance of Nickel Alloys in Aggressive Chemical Environments." Corrosion Science, 162, 108211.

Thompson, R.G. (2019). "High-Temperature Behavior of Nickel-Based Superalloys in Chemical Reactors." Materials Science and Engineering: A, 743, 321-335.

Liu, X.Y., et al. (2022). "Advances in Nickel Alloy Design for Next-Generation Chemical Processing Equipment." Progress in Materials Science, 123, 100721.

Garcia-Sanchez, E. & Fernandez-Gonzalez, D. (2020). "Fabrication Techniques for Complex Nickel Alloy Components in Chemical Industry Applications." Journal of Manufacturing Processes, 54, 275-289.

Patel, N.V. & Roberts, T.L. (2021). "Economic Impact of Nickel Alloy Usage in Chemical Processing: A Global Perspective." Chemical Engineering Research and Design, 168, 241-256.