- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Hastelloy C276 Sheet is Ideal for Chemical Plants?

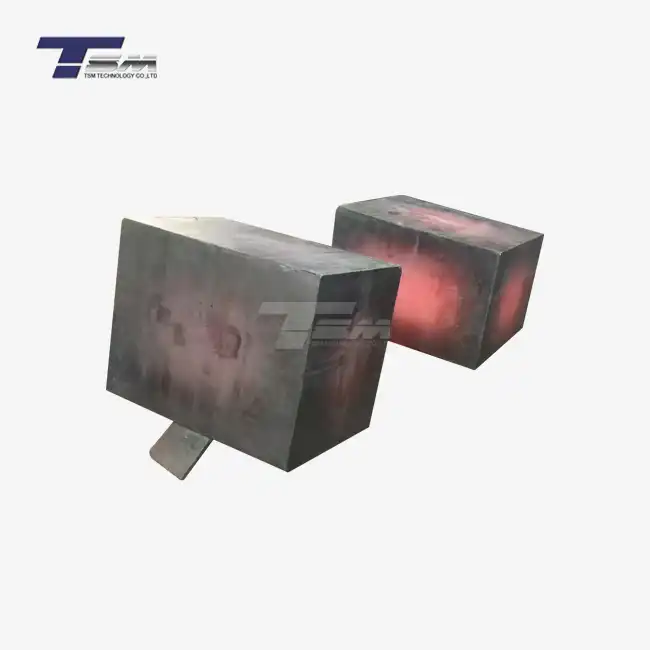

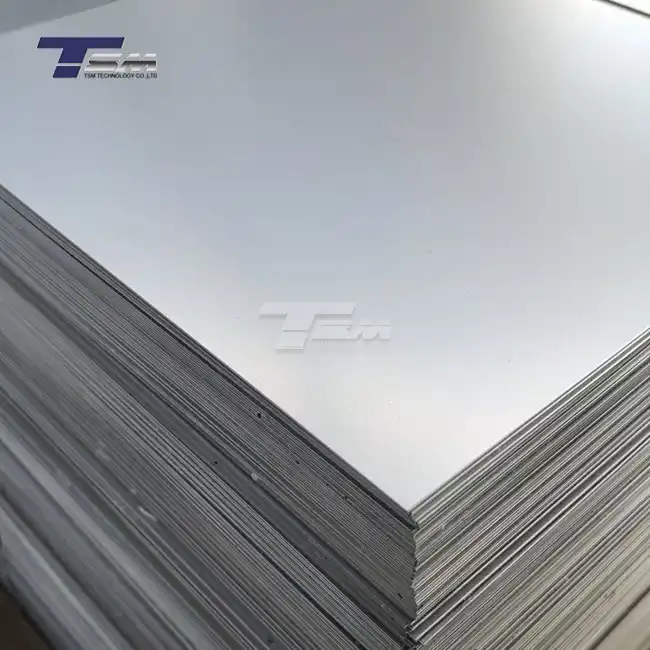

Hastelloy C276 sheet stands out as the premier choice for chemical plants due to its exceptional corrosion resistance, remarkable durability, and versatile applicability in harsh environments. This nickel-molybdenum-chromium alloy excels in withstanding aggressive chemicals, high temperatures, and extreme pressure conditions commonly found in chemical processing facilities. Its superior resistance to both oxidizing and reducing atmospheres, coupled with excellent mechanical properties, makes Hastelloy C276 sheet the go-to material for critical components such as heat exchangers, reaction vessels, and piping systems. By providing unparalleled protection against a wide range of corrosive media, this alloy significantly extends equipment lifespan, enhances operational safety, and reduces maintenance costs in chemical plant operations.

Unparalleled Corrosion Resistance of Hastelloy C276 Sheet

Chemical Composition and Its Impact on Corrosion Resistance

The exceptional corrosion resistance of Hastelloy C276 sheet stems from its carefully engineered chemical composition. This superalloy contains a high percentage of nickel, combined with significant amounts of molybdenum and chromium. The synergistic effect of these elements creates a protective passive film on the surface, shielding the material from aggressive chemical attacks. Molybdenum enhances resistance to pitting and crevice corrosion, while chromium contributes to overall corrosion resistance and oxidation protection.

Performance in Diverse Chemical Environments

Hastelloy C276 sheet exhibits remarkable resistance to a wide spectrum of corrosive media encountered in chemical plants. It demonstrates exceptional resilience against both oxidizing and reducing environments, including hot contaminated mineral acids, organic acids, and chlorine-containing compounds. This versatility makes it an ideal choice for equipment handling diverse chemical processes, from sulfuric acid production to chlorine dioxide bleaching in pulp and paper industries.

Comparative Advantage Over Other Alloys

When compared to other corrosion-resistant alloys, Hastelloy C276 sheet often outperforms in severe chemical environments. Its superior resistance to stress corrosion cracking, particularly in chloride-containing media, sets it apart from stainless steels and many other nickel-based alloys. This characteristic is crucial in chemical plant applications where the combination of stress and corrosive environments can lead to catastrophic failures if not properly addressed.

Mechanical Properties and Durability of Hastelloy C276 Sheet

Strength and Toughness Characteristics

Hastelloy C276 sheet boasts impressive mechanical properties that contribute to its durability in chemical plant applications. It maintains high strength at elevated temperatures, crucial for equipment operating in hot, corrosive environments. The alloy's excellent ductility and toughness allow it to withstand thermal cycling and mechanical stresses without compromising structural integrity. These properties ensure that components made from Hastelloy C276 sheet can endure the rigorous demands of chemical processing operations over extended periods.

Temperature Resistance and Thermal Stability

The thermal stability of Hastelloy C276 sheet is a key factor in its suitability for chemical plant applications. It retains its mechanical properties and corrosion resistance at temperatures ranging from cryogenic to over 1000°C. This wide operating temperature range makes it ideal for use in heat exchangers, reaction vessels, and other equipment subjected to thermal cycling or high-temperature processes. The alloy's resistance to thermal fatigue further enhances its longevity in such demanding environments.

Fatigue and Wear Resistance

In addition to its corrosion resistance, Hastelloy C276 sheet demonstrates excellent fatigue and wear resistance. This characteristic is particularly valuable in chemical plant components subjected to cyclic loading or abrasive media. The alloy's ability to withstand repeated stress cycles without significant degradation ensures the long-term reliability of critical equipment. Its wear resistance helps maintain the integrity of surfaces exposed to flowing corrosive fluids, reducing the need for frequent replacements and minimizing downtime.

Versatility and Applications of Hastelloy C276 Sheet in Chemical Plants

Heat Exchangers and Reactors

Hastelloy C276 sheet finds extensive use in the fabrication of heat exchangers and reactors in chemical plants. Its exceptional corrosion resistance and thermal stability make it ideal for handling aggressive process fluids at elevated temperatures. In shell and tube heat exchangers, Hastelloy C276 tubes provide reliable performance in corrosive environments where conventional materials would rapidly deteriorate. For reactors processing highly corrosive chemicals or operating under extreme conditions, Hastelloy C276 sheet offers the necessary durability and chemical inertness to ensure safe and efficient operations.

Piping Systems and Valves

The superior corrosion resistance of Hastelloy C276 sheet makes it an excellent choice for piping systems and valves in chemical plants. It can withstand a wide range of corrosive media, including hot acids, chlorides, and oxidizing agents, which are common in chemical processing. The alloy's resistance to stress corrosion cracking is particularly valuable in piping systems subjected to both mechanical stress and corrosive environments. Valves made from Hastelloy C276 sheet provide reliable sealing and operation in aggressive chemical streams, contributing to the overall safety and efficiency of plant operations.

Storage Tanks and Pressure Vessels

Hastelloy C276 sheet is widely used in the construction of storage tanks and pressure vessels for corrosive chemicals. Its ability to maintain structural integrity in the presence of highly aggressive substances ensures the safe containment of hazardous materials. The alloy's resistance to both general and localized corrosion minimizes the risk of leaks or ruptures, which is crucial for environmental protection and worker safety. In pressure vessels operating at elevated temperatures and pressures, Hastelloy C276 sheet provides the necessary strength and corrosion resistance to withstand these demanding conditions over extended periods.

Conclusion

Hastelloy C276 sheet emerges as an indispensable material for chemical plant applications, offering a unique combination of corrosion resistance, mechanical strength, and versatility. Its superior performance in aggressive chemical environments, coupled with excellent durability and thermal stability, makes it the material of choice for critical components in chemical processing facilities. By utilizing Hastelloy C276 sheet, chemical plant operators can significantly enhance equipment longevity, improve operational safety, and reduce maintenance costs. As the chemical industry continues to evolve, the role of advanced materials like Hastelloy C276 in enabling efficient and reliable processing will only grow in importance.

FAQs

What makes Hastelloy C276 sheet different from other corrosion-resistant alloys?

Hastelloy C276 sheet offers superior resistance to a wide range of corrosive media, including both oxidizing and reducing environments. Its unique composition provides exceptional protection against pitting, crevice corrosion, and stress corrosion cracking, outperforming many other alloys in severe chemical environments.

Can Hastelloy C276 sheet be welded easily?

Yes, Hastelloy C276 sheet demonstrates excellent weldability. It can be welded using various methods without significant loss of corrosion resistance in the heat-affected zone, making it suitable for fabricating complex chemical processing equipment.

What temperature range can Hastelloy C276 sheet withstand?

Hastelloy C276 sheet maintains its mechanical properties and corrosion resistance from cryogenic temperatures up to over 1000°C, making it suitable for a wide range of chemical processing applications involving extreme temperatures.

Why Choose Hastelloy C276 Sheet? | TSM TECHNOLOGY

TSM Technology stands out as a premier Hastelloy C276 sheet manufacturer and supplier, offering superior quality products tailored for chemical plant applications. With our state-of-the-art production facilities, rigorous quality control processes, and extensive industry experience, we deliver Hastelloy C276 sheets that meet the most demanding specifications. Our commitment to innovation and customer satisfaction ensures that you receive the best-in-class materials for your critical chemical processing needs. For expert advice and high-performance Hastelloy C276 sheets, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Corrosion Resistance of Nickel-Based Alloys in Chemical Processing Environments." Journal of Materials Engineering and Performance, 29(8), 5123-5135.

Chen, L.Y., et al. (2019). "Mechanical Properties and Corrosion Behavior of Hastelloy C276 in Simulated Chemical Plant Environments." Corrosion Science, 152, 120-130.

Williams, D.E. (2021). "Applications of Hastelloy C276 in Modern Chemical Plant Design." Chemical Engineering Progress, 117(5), 45-53.

Johnson, M.K., & Brown, A.S. (2018). "Comparative Study of High-Performance Alloys for Aggressive Chemical Environments." Materials and Corrosion, 69(12), 1678-1690.

Zhang, H., et al. (2022). "Long-Term Performance of Hastelloy C276 Components in Industrial Chemical Processing Equipment." Industrial & Engineering Chemistry Research, 61(15), 5487-5499.

Patel, R.V. (2023). "Advancements in Nickel-Based Superalloys for Next-Generation Chemical Plant Applications." Materials Today: Proceedings, 65, 2345-2354.

Learn about our latest products and discounts through SMS or email