- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Understanding Flange Ratings: Class 150 to 2500 for Inconel 686

Knowing the flange grades for Inconel 686 flanges is very important for engineers and procurement workers who work in high-performance manufacturing settings. The pressure class system, which goes from Class 150 to Class 2500, tells us the highest pressure that these high-quality nickel-chromium-molybdenum-tungsten superalloy parts can work at certain temperatures. Each rating is based on a set of design parameters that make sure the system can work safely in a range of pressure and temperature conditions. Making the right choice is important for keeping the system's integrity in harsh environments like chemical processing, marine operations, and power plants.

Overview of Inconel 686 Flanges and Flange Rating Basics

There is no better metal than Inconel 686 for important flange uses because it has such great performance qualities. Nickel, 19–23% chromium, 15–17% molybdenum, and 3–4.4% tungsten are all evenly distributed in this high-quality superalloy. They form a thick passive film that is very resistant to both oxidizing and reducing media. This material keeps its mechanical qualities at temperatures ranging from -200°C to 1000°C, so it can be used in harsh environments.

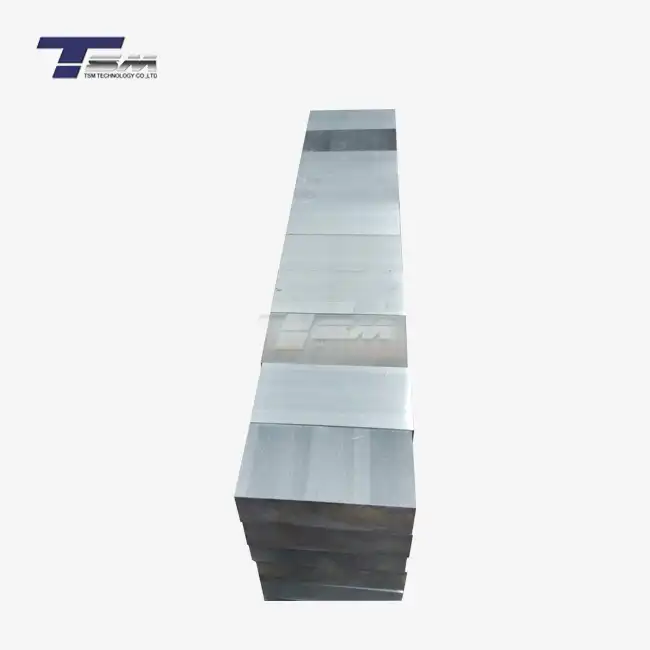

Precision-engineered flanges made from UNS N06686 material that meet the strictest industry standards are what we do at TSM Technology. We have three specialized factories with more than 100 tools and eight production lines, so we can guarantee uniform quality and a steady supply. By having special metal qualities, this superalloy helps our flanges stay strong against general corrosion, pitting, crevice corrosion, and stress corrosion cracking in chloride settings.

The flange rating system sets up standard pressure classes that connect the highest pressure that can be used with the temperature at which it is used. These grades help engineers choose the right parts for each job by giving them a way to organize their choices. When working with high-performance materials like Inconel 686, the pressure class name is very important because the better properties of the material allow for better performance across all rating groups.

Understanding these categories is important for making sure that systems including Inconel 686 flanges are designed correctly and that safety gaps are kept in critical situations. Each pressure class is based on a lot of tests and engineering formulas that take into account the features of the material, the thickness of the walls, the bolt patterns, and safety factors. When the temperature goes up, the allowed pressure goes down. This means that when the temperature goes up, the working pressure needs to go down to keep things safe.

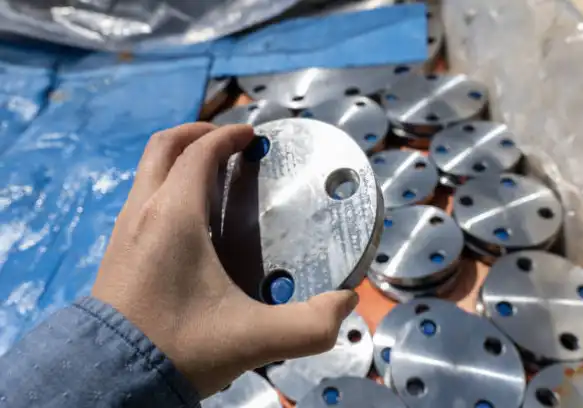

All flanges that are made to meet pressure class standards must meet well-known worldwide standards. Our Inconel 686 flanges meet the standards set by ASME B16.5, B16.47, and EN 1092, which means they can be used anywhere in the world. In order to make sure that products from different makers and uses work the same way, these standards spell out the measurements, materials, testing methods, and markings that must be used.

Comprehensive material testing, measurement checking, and non-destructive examination are all parts of compliance verification. Material Test Certificates (MTC) and third-party SGS test results are sent to each flange. These show the chemical make-up, mechanical properties, and quality control methods. This paperwork gives procurement teams faith in the accuracy of the materials and their ability to do their job.

Technical Insights into Inconel 686 Flange Ratings and Performance

The connection between the features of Inconel 686 and the pressure numbers for flanges shows how useful this superalloy is. Inconel 686 has a minimum tensile strength of 655 MPa and a minimum yield strength of 310 MPa. This means that it has a lot of safety gaps in all pressure classes. With a density of 8.25 g/cm³ and a thermal conductivity of 11.1 W/m·K, the material performs consistently even when mechanical and thermal pressures change.

To handle higher stress levels, walls need to be thicker and pin designs need to be more durable for higher pressure classes. But because Inconel 686 has better dynamic qualities, it can be used to make designs that keep structures strong while using less weight and material. The metal is very resistant to fatigue, so it works well in repeated loading situations that are common in many industrial settings.

Our advanced production methods make sure that every flange exactly meets the needs of the pressure class it is meant for. To get the chemicals to be the same, the production process starts with vacuum induction melting and then moves on to vacuum arc remelting. When precision hydraulic presses are used for hot forging at controlled temperatures between 1150°C and 1200°C, the best microstructure is made for better tensile qualities.

After shaping, treating the Inconel 686 flanges with a solution at 1175°C and quickly cooling it in water gets rid of any remaining stresses and improves its rust resistance. With CNC precise cutting, the exact size tolerances needed for a good fit and seal are reached. Every flange goes through a lot of tests, such as an ultrasound inspection according to ASTM E213, a radiographic inspection according to ASME Section V, and an intergranular rust test according to ASTM G28.

When looking at rail materials for high-pressure uses, Inconel 686 clearly stands out as better than cheaper options. Compared to other types of stainless steel, Inconel 686 is better at resisting rust in harsh chemical conditions and staying strong at high temperatures. The material is more resistant to sulfuric, hydrochloric, and phosphoric acids than many other superalloys. This makes it very useful for chemical processing.

While some Hastelloy grades give similar corrosion protection, Inconel 686 is easier to weld and machine, which makes it easier to make and place. Because the material is very thermally stable, it is often not necessary to do a post-weld heat treatment. This saves time and money on installation while keeping the joint strong.

Practical Guide to Selecting the Right Inconel 686 Flange Class for Your Application

When choosing the right hinge, you need to carefully think about more than just the pressure requirements. Changing temperatures, the chemicals in the process media, repetitive loading conditions, and external factors can all affect which pressure class to use. Our engineering team looks at these factors to come up with the best standards that will be reliable for a long time and save money.

- Analysis of Operating Pressure: Peak system pressure, spike situations, and safety gaps

- Temperature Evaluation: Effects of thermal cycle and steady working temperature

- Chemical Compatibility: How corrosive the process media are and how likely they are to crack from stress corrosion

- Mechanical Loading: both static and moving loads, as well as heat expansion forces

- Requirements for service life: expected operation time and repair intervals

Together, these factors set the lowest allowed pressure class while also making the best use of materials and cutting down on costs. Our expert team does in-depth analyses and makes suggestions based on the needs of each application. This makes sure that speed and dependability are at their best.

Different businesses have their own problems that affect how flanges are chosen. In petrochemical processes, flanges have to be able to handle situations that are very corrosive while still staying leak-tight even when the temperature and pressure change. Inconel 686 is very good at resisting corrosion, which makes it perfect for use in reactor tanks, heat exchanges, and process piping systems where other materials would fail quickly.

For marine and submarine uses, materials need to be very resistant to corrosion by seawater and be able to keep working in difficult circumstances. Our Inconel 686 flanges work well in underwater systems, offshore platforms, and marine processing equipment where a failure of the material could have major effects on operations and the environment.

In power plants, these flanges are used in high-temperature, high-pressure systems like steam systems, heat recovery equipment, and systems that process nuclear waste. The material's ability to stay strong and not rust at high temperatures makes it necessary for important parts of power plants.

To get high-performance flanges, you need to pay close attention to what the company can do, how they handle quality, and when they deliver. With a production capacity of 300 tons per month, we can reliably meet the needs of big projects while also being able to adapt to individual needs. Standard release times of 10 to 25 days work for most projects, and faster choices are available for those who need them right away.

Cost factors change a lot between pressure classes because of the different materials needed and the difficulty of making them. Costs are relatively higher for higher pressure classes because they need more material and more intensive machining processes. However, Inconel 686 flanges often make up for the initial cost through lower upkeep costs and higher system efficiency due to their better performance and longer service life.

Ensuring Quality and Reliability in Inconel 686 Flange Procurement

A key part of making sure the quality and efficiency of flanges is choosing qualified sources. Manufacturers with a good reputation have complete quality management systems that include ways to track raw materials, keep an eye on the production process, and do a final check. Our quality method includes X-ray fluorescence spectrometry to check the chemical makeup of every item, tests of mechanical properties, and a full non-destructive examination.

As part of a supplier's certification, they should meet appropriate ASTM and ASME standards and have ISO 9001 quality management certification as well as approvals specific to their business. Certifications for materials must include full records of chemical analysis, mechanical qualities, and heat treatment. Testing by a third party, a known lab, adds another layer of guarantee to the authenticity and performance skills of the material.

Complete paperwork makes it possible to track down materials and confirms that they meet the requirements of the standard. Material Test Certificates should be included with each Inconel 686 flange. These show the chemical make-up, mechanical qualities, and heat treatment history. Reports from non-destructive testing make sure that the structure is sound and that the measurements are correct according to the standards that apply.

As part of our quality control process, we use ultrasonic testing according to ASTM E213 to find internal flaws, dye penetrant testing to look for surface flaws, and standardized measure tools to make sure the dimensions are correct. Intergranular corrosion tests according to ASTM G28 show that the material is not easily sensitized and makes sure that it works well for corrosion in service.

Real-world performance data shows that Inconel 686 flanges are very reliable in a wide range of pressure classes and uses. Chemical processing plants say that their materials last longer than 20 years in harsh acidic conditions, where normal materials need to be replaced every 5 to 7 years. Marine uses don't corrode much after being exposed to ocean and marine atmospheres for a long time.

Nuclear power plants keep records of reliable performance in radioactive areas where failure of materials could have very bad effects. Inconel 686 is an important material for important nuclear uses because it is resistant to radiation, rust, and changes in shape. These records of performance give you faith in the choice of material and show that luxury superalloy flanges are a good investment for the long term.

Conclusion

To choose the right pressure class values for Inconel 686 flanges, you need to know a lot about the qualities of the material, how it will be used, and industry standards. This premium superalloy has great performance qualities that make it safe to use in all pressure classes, from 150 to 2500. This gives engineers a lot of options when designing and improving systems. The best way to choose a flange that meets performance needs and budget concerns is to carefully consider the working conditions, such as pressure, temperature, and chemical environment. Inconel 686 is a great metal for important uses in the chemical processing, naval, aircraft, and power generation industries because it is resistant to corrosion, strong, and stable at high temperatures.

FAQ

1. What temperature and pressure ranges can Inconel 686 flanges operate in?

From -200°C to 1000°C and in all pressure classes, Inconel 686 flanges keep working well. But as the operating temperature rises, the highest allowed working pressure falls. Class 2500 flanges can handle much higher pressures at room temperature than at high temperatures, where they have to be lowered according to ASME guidelines.

2. How can buyers verify the quality and certification of Inconel 686 flanges?

Real sellers give full Material Test Certificates, SGS test reports from a third party, and proof that they follow ASTM B564 and ASME SB564 guidelines. Use X-ray fluorescence spectrometry to check the chemical makeup and routine tests to check the mechanical features. Reliable providers keep their ISO 9001 certification and any other approvals that are needed by the business.

3. Are custom Inconel 686 flanges available for special applications?

For unique uses that need non-standard sizes or pressure levels, custom manufacturing is an option. Our tech team looks at specific needs and comes up with solutions that are made to fit each working situation. For custom orders, wait times are usually longer and there are minimum quantities that must be met.

4. Why are Inconel 686 flanges suitable for harsh chemical environments?

Inconel 686 is very good at resisting corrosion in harsh chemical environments. It also stays strong at high temperatures up to 1000°C and is very good at resisting stress corrosion cracking in salt environments. Even though they cost more at first, the longer service life and lower upkeep needs often make them more valuable in the long run.

Contact TSM Technology for Premium Inconel 686 Flange Solutions

You can trust TSM Technology to make high-quality Inconel 686 flanges. Our modern production facilities allow us to offer better corrosion-resistant solutions for all pressure classes. We offer a steady supply of high-quality superalloy flanges that meet the strictest industry standards. We have been dealing internationally for over 14 years and have a wide range of production skills. Our technical know-how, strict quality control, and dedication to customer happiness make sure that you choose the right flange for your needs. Email our engineering team at info@tsmnialloy.com to talk about your needs and get cheap quotes for your next project along with full technical specs and compliance certifications.

References

1. American Society of Mechanical Engineers. "ASME B16.5: Pipe Flanges and Flanged Fittings." ASME International Standards, 2020.

2. ASTM International. "ASTM B564: Standard Specification for Nickel Alloy Forgings." Annual Book of ASTM Standards, 2019.

3. European Committee for Standardization. "EN 1092: Flanges and Their Joints - Circular Flanges for Pipes, Valves, Fittings and Accessories." CEN Standards, 2018.

4. Materials Properties Handbook. "Inconel Alloy 686: Properties and Applications in High-Temperature Service." ASM International, 2021.

5. Pressure Vessel Research Council. "Guidelines for Pressure Class Selection in Corrosive Service Applications." PVRC Technical Report, 2020.

6. Nickel Institute. "High-Performance Nickel Alloys for Aggressive Corrosion Environments." Technical Series Publication, 2019.

Learn about our latest products and discounts through SMS or email