- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Welding and Fabrication Tips for Incoloy 825 Sheet

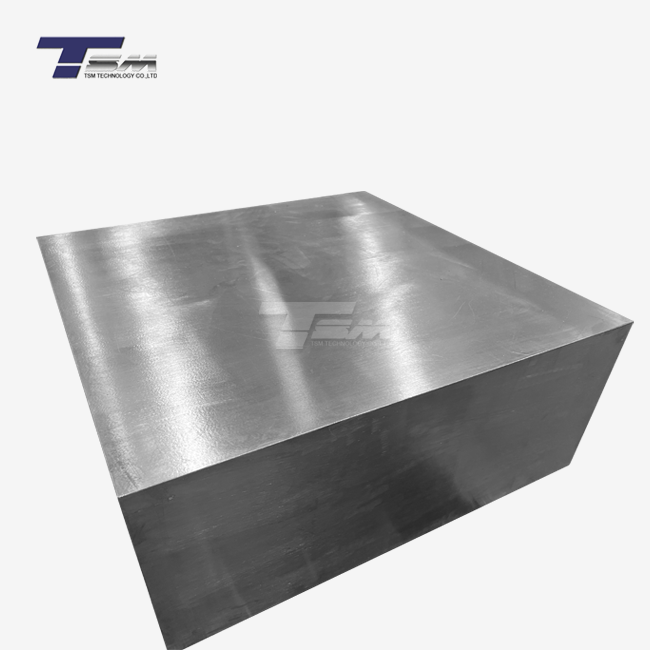

Incoloy 825 sheet is a versatile nickel-iron-chromium alloy known for its exceptional corrosion resistance and mechanical properties. When working with this high-performance material, proper welding and fabrication techniques are crucial to maintain its integrity and ensure optimal performance. This comprehensive guide explores essential tips and best practices for welding and fabricating Incoloy 825 sheet, covering preparation methods, welding techniques, and post-weld treatments. By following these recommendations, engineers and fabricators can maximize the alloy's potential and create durable, high-quality components for demanding applications in chemical processing, oil and gas, and marine industries.

Preparation and Material Handling

Surface Cleaning and Contamination Prevention

Before welding Incoloy 825 sheet, meticulous surface cleaning is critical to ensure weld integrity. All oils, greases, dirt, and other contaminants should be completely removed using suitable solvents or degreasers. For more persistent residues, light mechanical abrasion may be employed to achieve a clean surface. It is important to work with dedicated, uncontaminated tools and clean work surfaces to avoid cross-contamination with other metals, which could compromise corrosion resistance and welding quality during fabrication.

Edge Preparation Techniques

Achieving high-quality welds on Incoloy 825 plate depends heavily on proper edge preparation. For thicker sheets, mechanical cutting methods such as plasma or water jet cutting are recommended, followed by grinding to remove oxide layers. Thinner sheets can be effectively prepared using shearing or laser cutting techniques. Regardless of method, edges should be smooth, free of burrs, and properly aligned to ensure consistent weld penetration, reduce defects, and support the structural integrity of the finished component.

Storage and Handling Precautions

Incoloy 825 sheets must be stored and handled with care to preserve their surface quality and corrosion resistance. Sheets should be kept in a clean, dry environment to prevent moisture absorption and surface oxidation. When moving or handling the material, clean gloves should be used to avoid contamination from oils or dirt. For larger sheets, appropriate lifting equipment is necessary to prevent bending, scratching, or other damage while ensuring the safety of personnel during transport and installation.

Welding Techniques and Parameters

Recommended Welding Processes

Incoloy 825 sheet can be welded using several established processes, including Gas Tungsten Arc Welding (GTAW/TIG), Gas Metal Arc Welding (GMAW/MIG), and Shielded Metal Arc Welding (SMAW). GTAW is particularly favored for its precision and ability to produce clean, high-quality welds on thinner sheets, minimizing defects. For a thicker Incoloy 825 plate, GMAW is often chosen due to its higher deposition rates, improved productivity, and suitability for larger fabrication projects, while SMAW remains useful in field repairs or situations with limited equipment availability.

Filler Metal Selection

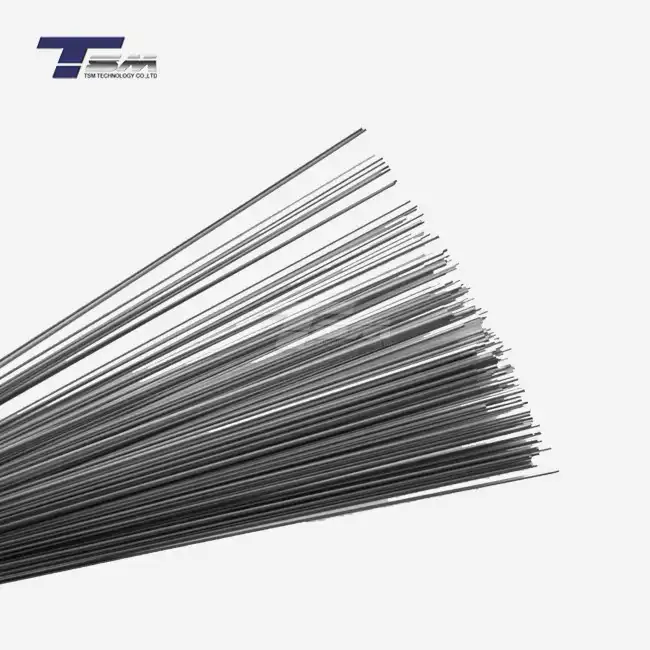

Selecting the appropriate filler metal is critical to maintaining the corrosion resistance and mechanical properties of welded Incoloy 825 components. Filler metals such as ERNiCrMo-3 for GTAW and GMAW, and ENiCrMo-3 for SMAW, closely match the base alloy composition. Filler metals must be properly stored, clean, and dry before welding to prevent contamination. Proper filler metal selection ensures weld integrity, uniform corrosion resistance, and compatibility with the thermal and mechanical properties of the Incoloy 825 base material.

Welding Parameters and Techniques

Effective welding of Incoloy 825 sheet requires careful control of heat input and welding technique. Low heat input minimizes distortion and reduces the risk of hot cracking, while stringer bead or narrow weave patterns help manage thermal effects. Use a direct current electrode negative (DCEN) for GTAW and a direct current electrode positive (DCEP) for GMAW to optimize arc stability. For thicker plates, preheating to 150–200°C (300–400°F) slows cooling rates, reduces residual stresses, and lowers the likelihood of hydrogen-induced cracking, ensuring durable, high-quality welds.

Post-Weld Treatments and Quality Control

Stress Relief and Heat Treatment

After welding, stress relief heat treatment may be necessary to reduce residual stresses and improve the overall performance of the welded Incoloy 825 component. Typical stress relief temperatures range from 870-980°C (1600-1800°F), followed by rapid cooling. Always consult specific material specifications and project requirements for precise heat treatment parameters.

Surface Finishing and Passivation

To restore corrosion resistance, remove any heat tint or oxide scale from the weld and heat-affected zone using mechanical or chemical cleaning methods. For optimal corrosion resistance, consider passivating the welded area using a nitric acid solution or electropolishing techniques. This process helps form a protective oxide layer on the surface of the Incoloy 825 sheet.

Non-Destructive Testing (NDT) Methods

Implement appropriate NDT methods to ensure weld quality and integrity. Common techniques for inspecting Incoloy 825 welds include visual inspection, dye penetrant testing, radiographic testing, and ultrasonic testing. Select the most suitable NDT method based on the specific application requirements and regulatory standards.

Conclusion

Mastering the welding and fabrication of Incoloy 825 sheet requires attention to detail, proper technique, and adherence to best practices. By following the guidelines outlined in this article, fabricators can achieve high-quality welds and maintain the exceptional properties of this versatile alloy. Remember that each project may have unique requirements, so always consult material specifications and industry standards for specific guidance. With the right approach, Incoloy 825 can be successfully fabricated into components that deliver outstanding performance in challenging environments.

FAQs

What is the ideal welding process for thin Incoloy 825 sheets?

Gas Tungsten Arc Welding (GTAW/TIG) is often preferred for thin Incoloy 825 sheets due to its precision and ability to produce high-quality welds.

Is preheating necessary when welding Incoloy 825?

Preheating is not always required, but can be beneficial for thicker sections. Preheating to 150-200°C (300-400°F) can help reduce cooling rates and minimize the risk of hydrogen-induced cracking.

How can I improve the corrosion resistance of welded Incoloy 825 components?

After welding, passivate the surface using a nitric acid solution or electropolishing techniques to form a protective oxide layer, enhancing corrosion resistance.

Expert Incoloy 825 Sheet Solutions | TSM TECHNOLOGY

At TSM Technology, we specialize in providing high-quality Incoloy 825 sheets and plates for demanding industrial applications. Our extensive experience and strict quality control ensure that you receive materials that meet the highest standards. For expert advice on welding and fabricating Incoloy 825 or to discuss your specific project needs, contact our team at info@tsmnialloy.com. Trust TSM Technology for superior alloy solutions and unparalleled customer support.

References

Davis, J.R. (Ed.). (2000). Nickel, Cobalt, and Their Alloys. ASM International.

DuPont, J.N., Lippold, J.C., & Kiser, S.D. (2009). Welding Metallurgy and Weldability of Nickel-Base Alloys. John Wiley & Sons.

Kou, S. (2003). Welding Metallurgy (2nd ed.). John Wiley & Sons.

Olson, D.L., Siewert, T.A., Liu, S., & Edwards, G.R. (Eds.). (1993). ASM Handbook, Volume 6: Welding, Brazing, and Soldering. ASM International.

Special Metals Corporation. (2013). Incoloy alloy 825 Technical Data Sheet.

American Welding Society. (2015). AWS D1.6/D1.6M: Structural Welding Code - Stainless Steel.

Learn about our latest products and discounts through SMS or email