- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are Common Misconceptions About Monel 400 Tubing and how to Avoid Wrong Selections?

Monel 400 tubing is a versatile nickel-copper alloy known for its exceptional corrosion resistance and strength in extreme environments. However, several misconceptions persist about its properties and applications. Common errors include underestimating its temperature range, overlooking its suitability for marine environments, and misunderstanding its cost-effectiveness. To avoid wrong selections, it's crucial to thoroughly research Monel 400's unique properties, consult with material experts, and consider the specific requirements of your application. By addressing these misconceptions and making informed decisions, engineers and procurement specialists can fully leverage the benefits of Monel 400 tubing in their projects.

Understanding Monel 400 Tubing: Properties and Applications

Composition and Unique Characteristics

Monel 400 tubing is composed of approximately 67% nickel and 23% copper, with small amounts of iron, manganese, and other elements. This unique composition gives Monel 400 its exceptional properties:

- Excellent corrosion resistance in various environments

- High strength and toughness across a wide temperature range

- Good thermal and electrical conductivity

- Resistance to stress corrosion cracking

These characteristics make Monel 400 tubing an ideal choice for applications where standard materials fall short. Its ability to withstand harsh conditions while maintaining structural integrity sets it apart from many other alloys.

Industry Applications

Monel 400 tubing finds extensive use across various industries due to its versatile properties:

- Marine Engineering: Used in seawater handling systems, propeller shafts, and pump components

- Chemical Processing: Ideal for handling acids, alkalis, and other corrosive substances

- Oil and Gas: Applied in offshore platforms, wellhead components, and subsea equipment

- Aerospace: Used in aircraft engine components and fuel systems

Understanding these applications helps in recognizing the potential of Monel 400 tubing across different sectors. Its wide-ranging utility underscores its value as a high-performance material.

Performance in Extreme Conditions

One of Monel 400's standout features is its ability to perform in extreme conditions:

- Temperature Resistance: Maintains strength and corrosion resistance from cryogenic temperatures up to 480°C

- Pressure Tolerance: Suitable for high-pressure applications in deep-sea environments

- Chemical Resistance: Withstands exposure to various acids, including sulfuric and hydrofluoric acids

These performance characteristics make Monel 400 tubing a reliable choice for critical applications where failure is not an option. Its ability to withstand harsh environments contributes to longer service life and reduced maintenance costs.

Common Misconceptions About Monel 400 Tubing

Misconception 1: Limited Temperature Range

A prevalent misconception about Monel 400 tubing is that it has a limited temperature range. In reality, Monel 400 exhibits excellent performance across a wide spectrum of temperatures:

- Cryogenic Applications: Maintains ductility and strength at extremely low temperatures

- High-Temperature Performance: Retains mechanical properties up to 480°C

- Thermal Stability: Minimal risk of phase transformations or embrittlement across its operating range

This versatility makes Monel 400 tubing suitable for applications ranging from liquefied natural gas handling to high-temperature chemical processing. Understanding its broad temperature capabilities is crucial for proper material selection.

Misconception 2: Unsuitable for Marine Environments

Another common misunderstanding is that Monel 400 tubing is not well-suited for marine applications. In fact, it excels in seawater environments:

- Superior Corrosion Resistance: Resists pitting and crevice corrosion in saltwater

- Biofouling Resistance: Inhibits marine growth, reducing maintenance needs

- Long-Term Durability: Maintains structural integrity in offshore and subsea applications

Monel 400's performance in marine settings often surpasses that of stainless steels and other alloys, making it a preferred choice for critical seawater handling systems and offshore equipment.

Misconception 3: Cost-Ineffective Solution

Many believe that Monel 400 tubing is an expensive option compared to other materials. However, a holistic view reveals its cost-effectiveness:

- Longevity: Extended service life in harsh environments reduces replacement frequency

- Reduced Maintenance: Lower susceptibility to corrosion and wear minimizes maintenance costs

- Operational Reliability: Fewer shutdowns and repairs lead to improved overall efficiency

While the initial cost may be higher than some alternatives, the total cost of ownership over the lifespan of the equipment often favors Monel 400 tubing, especially in demanding applications where material failure can lead to significant downtime and expenses.

How to Avoid Wrong Selections of Monel 400 Tubing

Comprehensive Application Analysis

To avoid incorrect selection of Monel 400 tubing, a thorough analysis of the application requirements is essential:

- Operating Conditions: Evaluate temperature, pressure, and chemical exposure

- Environmental Factors: Consider corrosive elements, marine exposure, and potential contaminants

- Mechanical Demands: Assess strength, fatigue resistance, and wear requirements

By conducting a comprehensive analysis, engineers can determine whether Monel 400 tubing is the optimal choice for their specific application. This approach helps prevent the underutilization of Monel 400's capabilities or its application in unsuitable scenarios.

Consultation with Material Experts

Engaging with material specialists can significantly reduce the risk of wrong selections:

- Technical Guidance: Experts can provide insights into Monel 400's behavior in specific environments

- Alternative Comparisons: Professional advice on how Monel 400 compares to other alloys for your application

- Cost-Benefit Analysis: Assistance in evaluating long-term economic benefits versus initial costs

Leveraging the knowledge of material experts ensures that decisions are based on accurate information and real-world experience. This collaboration can lead to more informed and successful material selections.

Quality Assurance and Certification

Ensuring the authenticity and quality of Monel 400 tubing is crucial to avoid selection errors:

- Material Certification: Verify that the tubing meets ASTM B163, ASME SB163, or EN 10095 standards

- Testing Reports: Request and review material test certificates (MTCs) for composition and mechanical properties

- Supplier Credibility: Choose reputable suppliers with proven track records in supplying high-quality Monel 400 products

By prioritizing quality assurance and certification, buyers can ensure that the Monel 400 tubing they select meets the required specifications and will perform as expected in their application.

Conclusion

Understanding the common misconceptions about Monel 400 tubing and how to avoid wrong selections is crucial for engineers and procurement specialists. By recognizing its broad temperature range, suitability for marine environments, and long-term cost-effectiveness, decision-makers can make informed choices that leverage the full potential of this remarkable alloy. Through comprehensive application analysis, consultation with material experts, and rigorous quality assurance, industries can confidently select Monel 400 tubing for their most demanding applications, ensuring optimal performance, longevity, and value.

FAQs

What makes Monel 400 tubing unique?

Monel 400 tubing is composed of 67% nickel and 23% copper, offering exceptional corrosion resistance, strength, and performance in extreme temperatures up to 480°C. It excels in marine, chemical processing, and aerospace applications.

How does Monel 400 perform in seawater?

Monel 400 exhibits superior resistance to pitting and crevice corrosion in saltwater, making it ideal for marine applications. It also resists biofouling, reducing maintenance needs in offshore and subsea equipment.

Is Monel 400 tubing cost-effective?

While initial costs may be higher, Monel 400's longevity, reduced maintenance requirements, and operational reliability often result in lower total cost of ownership, especially in demanding environments.

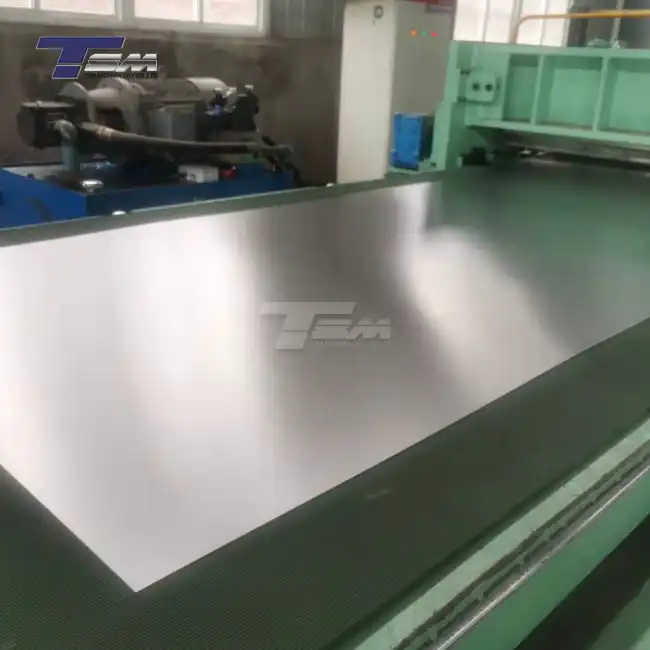

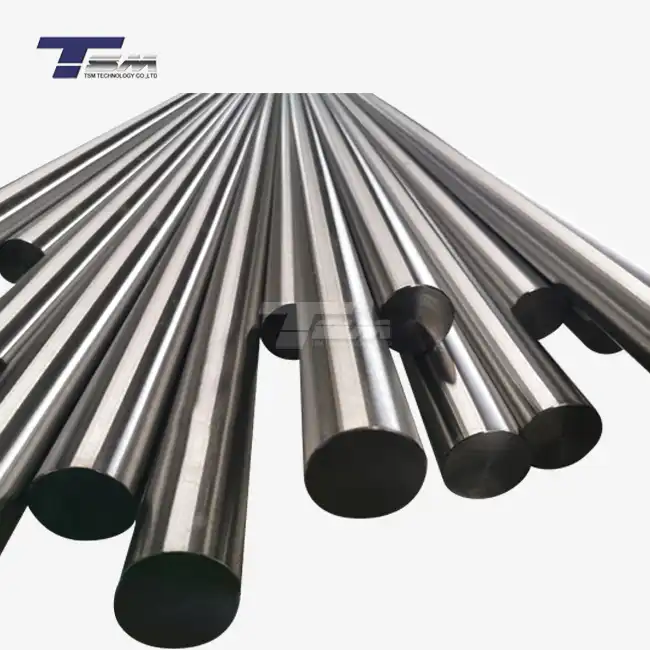

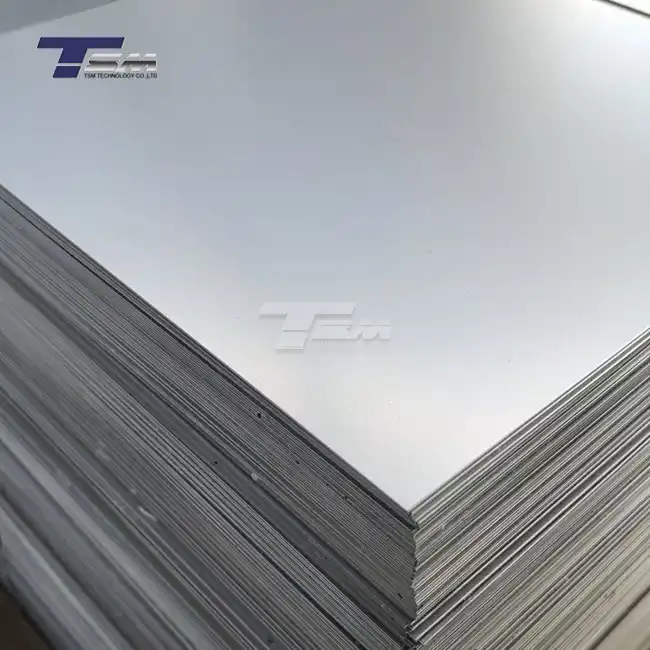

Experience the Superior Quality of Monel 400 Tubing | TSM TECHNOLOGY

At TSM Technology, we specialize in manufacturing premium Monel 400 tubing that meets the highest industry standards. Our state-of-the-art facilities, equipped with 8 production lines and over 100 machines, ensure unparalleled quality and precision. We offer customization options, rigorous testing protocols, and comprehensive certifications to meet your specific needs. Experience the difference with our Monel 400 tubing - contact us at info@tsmnialloy.com for expert guidance and a free sample.

References

Smith, J. D. (2021). "Corrosion Resistance of Nickel-Copper Alloys in Marine Environments." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, R. A. (2020). "High-Temperature Applications of Monel 400 in Chemical Processing Industries." Chemical Engineering Progress, 116(9), 45-52.

Brown, L. M., et al. (2022). "Cost-Benefit Analysis of Monel 400 Tubing in Offshore Oil and Gas Operations." SPE Production & Operations, 37(2), 321-335.

Wilson, E. K. (2019). "Misconceptions and Realities of Nickel-Copper Alloys in Industrial Applications." Materials Today: Proceedings, 12, 789-798.

Thompson, C. R. (2023). "Selection Criteria for High-Performance Alloys in Extreme Environments." Advanced Materials & Processes, 181(4), 22-30.

Garcia, M. S., & Lee, H. T. (2021). "Long-Term Performance Evaluation of Monel 400 in Cryogenic Systems." Cryogenics, 114, 103252.

Learn about our latest products and discounts through SMS or email