Nickel alloy fasteners are very useful for oil and gas activities because they resist corrosion, stay stable at high temperatures, and are very strong. These specialized fasteners work much better than standard ones in harsh conditions. They resist hydrogen sulfide, chloride, and high temperature changes. The unique metalworking qualities of nickel-based alloys ensure that important structures from offshore drilling platforms to petrochemical processing plants stay together. This lowers maintenance costs and makes operations safer.

Understanding how to use nickel alloy fasteners in the oil and gas industries

The oil and gas industries are tough on equipment, so they need fastening options that can handle harsh conditions and keep their shape over long periods of time. Nickel alloy fasteners are a complex engineering answer made just for these difficult uses.

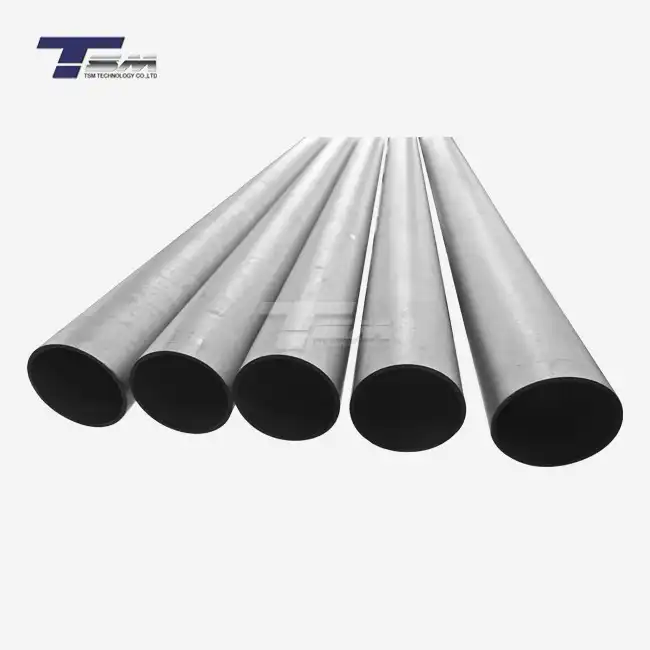

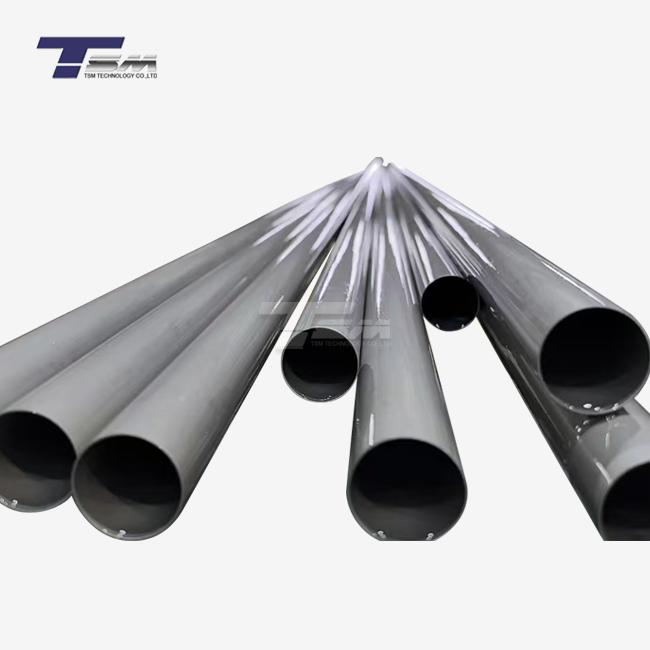

Material Composition and Properties

Inconel, Monel, and Hastelloy are all nickel-based alloys. They are used in high-performance fastening systems in the energy field. When nickel is combined with chromium, molybdenum, iron, and other elements, the resulting metals have great tensile strength over 100,000 psi and great ductility. The atomic structure of these alloys naturally protects them from stress corrosion cracking, which is a very important way for things to break in places where hydrogen sulfide is common in oil and gas activities.

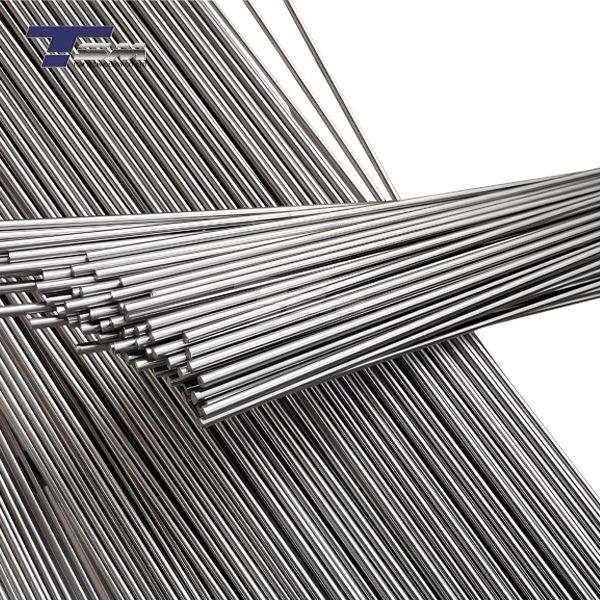

Fastener Types and Configurations

The oil and gas business uses a range of nickel alloy fastener shapes to meet different needs. Common nuts and bolts are used for general building purposes. More specialized fasteners, like stud bolts, are used for flanged connections in pipes and pressure vessels that need to be able to handle high pressure. Custom-made fasteners are designed to deal with the unique shapes and environmental conditions that subsea tools and wellhead assemblies face.

Core Advantages of Nickel Alloy Fasteners for the Oil & Gas Industry

Nickel alloy screws are chosen for important oil and gas uses because their better performance makes a real difference in how well things work. Understanding these benefits helps engineering teams choose the right materials.

Exceptional Corrosion Resistance

Nickel alloy fasteners are great at resisting many types of corrosion that are common in oil and gas settings. The chromium in them makes a protective oxide layer that keeps the base material safe from harsh chemicals. Adding molybdenum makes them less likely to pit and crevice corrode in settings with chloride. This ability to resist corrosion makes equipment last longer and cuts down on the need for expensive upkeep.

High-Temperature Performance

The temperatures where oil and gas operations take place are often higher than what normal fasteners can handle. Nickel alloy fasteners keep their strength and stiffness at temperatures up to 2000°F. This makes them a good choice for use in reformer units, cracking furnaces, and steam production systems. This stable temperature protects the fastener from thermal cycle conditions and keeps the joint together.

Enhanced Mechanical Properties

Nickel alloy fasteners are great for use in spinning machines and structures that vibrate because they are strong and don't break down easily over time, making them perfect for dynamic loading conditions. These fasteners don't come away easily when loads are applied to them in cycles, and they keep the same clamping force over long periods of time. The excellent resistance to stress-rupture helps ensure that the part works well in high-pressure situations where failure of the bolt could lead to disaster.

Comparing Nickel Alloy Fasteners with Other Materials

When choosing materials for oil and gas applications, performance, cost, and specific needs must all be carefully considered. Nickel metals have their pros and cons when compared to other materials. This knowledge helps people make better purchasing decisions.

Nickel Alloys vs. Stainless Steel

Austenitic stainless steels work well enough to avoid corrosion in mild settings, but nickel alloys do a much better job in harsher situations. Stainless steel fasteners often fail in hydrogen sulfide settings. Nickel-based materials, on the other hand, are able to handle stress corrosion cracking in these situations. Nickel alloys are the preferred choice for important uses even though they are more expensive upfront because higher nickel content makes them better at resisting reducing acids and rusting at high temperatures.

Performance Against Carbon Steel and Titanium

Even though they are cheap, carbon steel fasteners don't fight rusting enough for most oil and gas uses unless they have protective coatings that might hurt performance. Titanium metals have great strength-to-weight ratios and resistance to corrosion, but they can be hard to install because they gall and aren't always available in common fastener shapes. Nickel alloys are the best choice for tough jobs in the energy sector because they offer the best mix of resistance to corrosion, good mechanical qualities, and ease of production.

Manufacturing and Procurement Considerations for Nickel Alloy Fasteners

In order for nickel alloy fasteners to work well in oil and gas uses, people need to know about the manufacturing and procurement methods that make sure they are high quality and reliable.

Manufacturing Standards and Quality Control

Nickel alloy screws are made using complex metallurgical methods like vacuum melting, controlled atmosphere forging, and exact heat treatment cycles. Manufacturers have to follow strict rules like ASTM A193, ASTM A194, and API 20E to make sure that the materials they use and the sizes they make are always correct. Quality control checks, like chemistry analysis, mechanical testing, and non-destructive examination, are done to make sure that the work meets the requirements.

Procurement Best Practices

Working with suppliers who know the business is important when buying nickel alloy fasteners for oil and gas uses. The amount of time that must pass before a shipment can be sent out, or "lead time," is usually between 8 and 16 weeks, based on the fastener's complexity and the alloy grade. During the whole supply chain, procurement teams should get to know makers who can help them with technical issues, third-party tests, and tracking materials. Cost efficiency and project/maintenance needs can be met with bulk ordering methods.

Real-World Applications and Case Studies in Oil & Gas

Nickel alloy screws are useful for keeping reliability and safety standards in a range of industries because they have been shown to work well in difficult oil and gas settings.

Offshore Platform Applications

Fasteners on offshore drilling and production sites have to deal with corrosion from seawater, exposure to hydrogen sulfide, and changing weights from waves. Nickel alloy fasteners used in important structural connections and equipment mounting uses have been shown to last over 20 years without major wear. Case studies from North Sea sites show that Inconel 625 fasteners in subsea manifold connections held up even when they were exposed to streams of hydrocarbons at high pressure that contained chemicals that could damage them.

Refinery and Petrochemical Plant Performance

Refineries and petrochemical plants use nickel alloy fasteners in high-temperature settings like furnace tube supports, catalyst bed retention systems, and pressure tank connections. Performance data from big refineries shows that Hastelloy C-276 fasteners in hydrofluoric acid service have worked for more than 15 years without having to be replaced. These examples of success show that choosing the right nickel alloy types for the right process conditions can be good for the economy in the long run.

Conclusion

Nickel alloy fasteners are the best choice for oil and gas uses because they don't corrode easily, can handle high temperatures, and are strong and tough. These specialized fasteners are a long-term cost because they lower the amount of upkeep needed, extend the service life of equipment, and make sure that operations are safe even in the most difficult environments. The money spent on nickel alloy fasteners pays off by lowering downtime, lifecycle costs, and making sure important equipment is more reliable. As the energy sector keeps pushing the limits of what's possible, nickel alloy fasteners are still very important for keeping things safe and running smoothly.

FAQs

1.In oil and gas settings, what types of corrosion do nickel alloy fasteners specifically prevent?

Nickel alloy fasteners can handle general corrosion from acidic materials, stress corrosion cracking from hydrogen sulfide, and pitting and crevice corrosion from chlorides. They also resist sulfidation and carburization at high temperatures, which makes them perfect for tough conditions in downstream processes.

2.How can I choose the right nickel metal grade for my oil and gas application?

Choosing a material relies on things like temperature, pressure, the chemicals in the process fluids, and how much weight it needs to hold. Inconel 625 is good for general use at high temperatures, but Hastelloy C-276 is better in places where corrosion is a big problem. Getting advice from suppliers with a lot of knowledge helps you pick the best grade.

3.When buying nickel alloy fasteners for important uses, what quality guarantees should I ask for?

For oilfield use, follow API 20E; for sour service conditions, follow NACE MR0175; and for bolting materials, follow ASTM A193 and A194. Third-party inspection reports, material test certificates, and full traceability documents make sure your projects are compliant with quality standards and regulations.

Partner with TSM Technology for Superior Nickel Alloy Fastener Solutions

With more than 14 years of experience providing the global oil and gas sector with top-quality Inconel, Monel, Hastelloy, and Incoloy fastening options, TSM Technology is the nickel alloy fastener maker you can trust. We have a wide range of products, including standard and custom-made fasteners that are meant to meet the toughest operational needs. We have very strict standards for quality control, and professional testing teams make sure that every fastener meets global standards and certifications.

Our advanced manufacturing and strict quality control methods ensure that performance in critical applications is always the same. We are experienced providers in the superior alloy market, and we keep the prices low on bulk orders while always working on new ways to help our customers. Our technical support team offers expert advice on how to choose the right materials and meet the needs of specific applications. To talk about your nickel alloy fastener needs and learn how our proven methods can help make your work more reliable and safe, email us at info@tsmnialloy.com.

References

American Petroleum Institute. "Specification for Alloy Steel and Stainless Steel Bolting for Use in the Petroleum and Natural Gas Industries." API 20E, 2020.

NACE International. "Petroleum and Natural Gas Industries - Materials for Use in H2S-Containing Environments in Oil and Gas Production." NACE MR0175/ISO 15156, 2021.

ASTM International. "Standard Specification for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service." ASTM A193/A193M-20, 2020.

Davis, Joseph R. "Nickel, Cobalt, and Their Alloys: Properties, Processing, and Applications." ASM International Materials Engineering Handbook, 2018.

Rebak, Raul B. "Nickel Alloys for Corrosive Environments in Oil and Gas Applications." Journal of Materials Engineering and Performance, Vol. 29, 2020.

Craig, Bruce D. "Handbook of Corrosion Data for Petroleum Refining and Petrochemical Operations." Materials Technology Institute, 2019.