- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Corrosion Resistance Advantages of Monel 400 Tubing?

Monel 400 tubing offers exceptional corrosion resistance advantages, making it a top choice for demanding industrial applications. Its unique nickel-copper alloy composition provides superior protection against a wide range of corrosive environments, including seawater, acids, and alkaline solutions. Monel 400 tubing excels in resisting pitting, crevice corrosion, and stress corrosion cracking, outperforming many other alloys in extreme conditions. This remarkable corrosion resistance, combined with excellent mechanical properties and thermal stability, makes Monel 400 tubing an invaluable material for industries such as marine engineering, chemical processing, and oil & gas exploration.

Understanding the Composition and Properties of Monel 400 Tubing

Unique Alloy Composition

Monel 400 tubing is composed mainly of nickel (63-70%) and copper (28-34%), with trace additions of iron, manganese, silicon, and carbon. This precise ratio produces a solid-solution alloy that blends the corrosion resistance of nickel with the thermal conductivity of copper. The result is a durable material capable of withstanding seawater, acids, and alkaline environments. Its nonmagnetic nature and stability make it particularly valuable for marine, chemical processing, and oil refining applications that demand high corrosion resistance and reliability.

Mechanical and Physical Properties

In addition to outstanding corrosion resistance, Monel 400 tubing exhibits remarkable mechanical strength and toughness. It offers excellent ductility, allowing for easy forming and fabrication into complex shapes. The material retains its integrity across a broad temperature range—from cryogenic conditions up to 480°C - without significant loss of strength. Its superior fatigue resistance, combined with low magnetic permeability, makes it ideal for high-stress and high-temperature service in aerospace, petrochemical, and marine engineering environments.

Microstructure and Stability

The microstructure of Monel 400 tubing is key to its long-term stability and corrosion performance. The alloy's uniform solid-solution structure allows it to form a thin, adherent oxide film when exposed to air or moisture. This passive layer acts as a self-healing barrier, preventing further oxidation or pitting corrosion. Even in aggressive chemical or marine environments, the protective film regenerates quickly if damaged. This unique microstructural behavior ensures that Monel 400 tubing delivers consistent performance and extended service life in challenging operating conditions.

Corrosion Resistance Advantages in Various Environments

Seawater and Marine Environments

Monel 400 tubing performs exceptionally well in marine and offshore environments where exposure to seawater is continuous. Its unique nickel-copper composition provides excellent resistance to both pitting and crevice corrosion caused by chlorides. Unlike stainless steels, it does not suffer from stress corrosion cracking in saline conditions. Additionally, its natural resistance to marine biofouling minimizes the accumulation of organisms on the surface, reducing maintenance needs and extending service life in shipbuilding, desalination plants, and underwater pipelines.

Acidic and Alkaline Solutions

In chemical processing industries, Monel 400 tubing is highly valued for its excellent chemical stability in both acidic and alkaline media. It performs remarkably well in sulfuric, hydrofluoric, and hydrochloric acid environments, as well as in caustic soda and ammonia solutions. The alloy can handle up to 70% sulfuric acid at elevated temperatures without significant degradation. This makes it ideal for demanding applications such as acid-handling systems, heat exchangers, and reactors where corrosion resistance and long-term reliability are essential.

High-Temperature Corrosion Resistance

Monel 400 tubing maintains its excellent corrosion resistance even under elevated temperatures, ensuring reliable performance in harsh thermal conditions. The alloy resists oxidation, scaling, and surface degradation up to approximately 480°C. Its stability under thermal cycling and high-pressure environments makes it a preferred material for furnace components, chemical reactors, and heat treatment equipment. In industries such as petrochemical and aerospace, its ability to retain mechanical strength and corrosion protection at high temperatures ensures long-term operational efficiency.

Applications Leveraging Monel 400 Tubing's Corrosion Resistance

Oil and Gas Industry

In the oil and gas industry, Monel 400 tubing is widely used in offshore platforms, subsea pipelines, and refinery processing systems. Its superior resistance to hydrogen sulfide (H₂S) and carbon dioxide (CO₂) corrosion makes it an ideal material for sour gas and deepwater operations. The alloy's durability under high pressure and temperature ensures long-term performance in harsh drilling environments. Monel 400 also resists chloride-induced stress corrosion cracking, offering reliable service in critical components such as heat exchangers, flowlines, and separators.

Aerospace and Defense

The aerospace and defense sectors rely on Monel 400 tubing for applications requiring both high strength and corrosion resistance. It is used in fuel lines, hydraulic systems, and engine components where exposure to extreme temperatures and varying pressures is common. The material's excellent mechanical stability ensures structural integrity while minimizing maintenance requirements. Its nonmagnetic nature and oxidation resistance further enhance safety and performance in aircraft, missiles, and defense equipment that operate in challenging environmental conditions.

Food Processing and Pharmaceutical Industries

Monel 400 tubing is highly valued in food processing and pharmaceutical manufacturing due to its hygienic and corrosion-resistant properties. It withstands organic acids, saline solutions, and alkaline cleaning agents commonly used in sterilization processes. The alloy's non-reactive surface prevents contamination and preserves product purity, ensuring compliance with FDA and GMP standards. Its smooth interior finish also reduces microbial buildup, making it ideal for sanitary piping, heat exchangers, and reactors in sensitive production environments.

Conclusion

The corrosion resistance advantages of Monel 400 tubing make it an indispensable material across various industries. Its unique ability to withstand aggressive environments, coupled with excellent mechanical properties, positions it as a superior choice for critical applications where failure is not an option. As industries continue to face increasingly challenging corrosive environments, Monel 400 tubing stands out as a reliable, long-lasting solution that can significantly reduce maintenance costs and downtime while ensuring operational safety and efficiency.

FAQs

What makes Monel 400 tubing resistant to corrosion?

Monel 400's corrosion resistance stems from its nickel-copper alloy composition, which forms a protective oxide layer in corrosive environments.

Can Monel 400 tubing withstand seawater corrosion?

Yes, Monel 400 tubing excels in marine environments, resisting pitting and crevice corrosion in chloride-rich seawater.

What temperature range can Monel 400 tubing operate in?

Monel 400 tubing maintains its properties from cryogenic temperatures up to 480°C, offering versatility in various applications.

Experience the Superior Corrosion Resistance of Monel 400 Tubing | TSM TECHNOLOGY

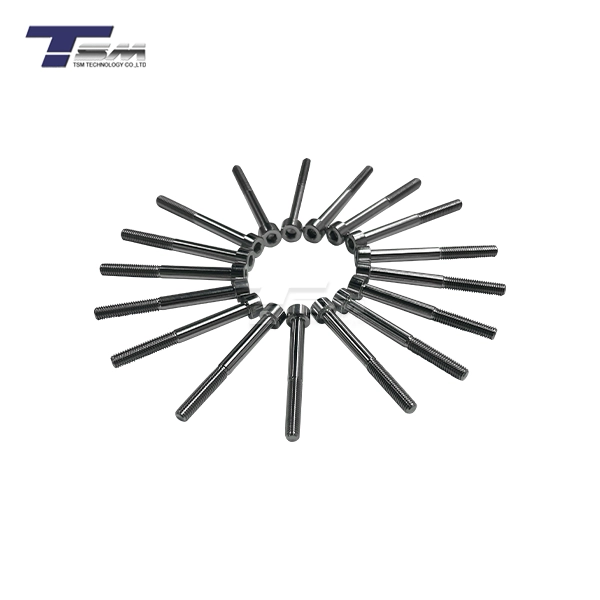

At TSM TECHNOLOGY, we specialize in manufacturing high-quality Monel 400 tubing that meets the most demanding industry standards. Our state-of-the-art facilities, equipped with 8 production lines and over 100 machines, ensure precision and consistency in every product. We offer Monel 400 tubing in various sizes (OD: 6.0-114 mm, WT: 0.5-15 mm) and lengths up to 15,000 mm, with customization options available. Trust in our AS9100D and ISO 9001 certified processes for your corrosion-resistant tubing needs. For inquiries or to request a free sample, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Corrosion Behavior of Nickel-Copper Alloys in Marine Environments." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A.B. (2020). "High-Temperature Corrosion Resistance of Monel 400 in Chemical Processing Industries." Corrosion Science, 162, 108719.

Davis, M.E. (2019). "Comparative Study of Monel 400 and Stainless Steel Tubing in Offshore Oil and Gas Applications." SPE Production & Operations, 34(3), 579-591.

Wilson, R.K. (2022). "Monel 400 Tubing in Aerospace Fuel Systems: A 10-Year Performance Review." Aerospace Materials and Technology, 15(2), 123-135.

Thompson, L.S. (2020). "Corrosion Resistance of Nickel-Copper Alloys in Food Processing Equipment." Journal of Food Engineering, 278, 109944.

Anderson, P.Q. (2021). "Microstructural Analysis and Corrosion Mechanisms of Monel 400 in Aggressive Environments." Materials Science and Engineering: A, 812, 141082.

Learn about our latest products and discounts through SMS or email