Understanding the Microstructure of 718 Sheet

Grain Structure and Its Importance

The grain structure of the 718 sheet plays a crucial role in determining its mechanical properties. Smaller grain sizes generally result in higher strength and improved fatigue resistance. Understanding grain structure is essential for predicting the material's behavior under various conditions.

Key Precipitate Phases in 718 Sheet

718 sheet derives its exceptional properties from its complex microstructure, which includes several important precipitate phases. The primary strengthening phases are γ' (gamma prime) and γ" (gamma double prime), while other phases like delta and various carbides also contribute to the alloy's characteristics.

Relationship Between Microstructure and Mechanical Properties

The microstructure of 718 sheet directly influences its mechanical properties. The distribution and size of precipitates, as well as the grain size, affect strength, ductility, and creep resistance. A thorough understanding of this relationship is crucial for optimizing the material's performance in specific applications.

Methods for Testing Grain Size in 718 Sheet

Optical Microscopy Techniques

Optical microscopy is a fundamental method for analyzing grain size in 718 sheet. This technique involves sample preparation through polishing and etching, followed by examination under a light microscope. The grain boundaries are revealed, allowing for measurement and analysis according to ASTM E112 standards.

ASTM E112 Standard for Grain Size Determination

ASTM E112 provides standardized methods for determining average grain size. These include comparison charts, the planimetric (Jeffries) method, and intercept procedures. Each method has its advantages and is suitable for different types of grain structures.

Advanced Imaging Techniques for Precise Grain Analysis

For more precise grain analysis, advanced techniques such as electron backscatter diffraction (EBSD) can be employed. EBSD provides detailed information about grain orientation and size distribution, offering a more comprehensive understanding of the material's microstructure.

Analyzing Precipitate Phases in 718 Sheet

Scanning Electron Microscopy (SEM) for Phase Identification

SEM is a powerful tool for analyzing precipitate phases in 718 sheet. It provides high-resolution images of the microstructure, allowing for the identification and characterization of various phases. When combined with energy-dispersive X-ray spectroscopy (EDS), SEM can also provide information about the chemical composition of these phases.

Transmission Electron Microscopy (TEM) for Nanoscale Analysis

TEM offers even higher resolution than SEM, making it ideal for studying the nanoscale features of precipitate phases. This technique can reveal the crystal structure and orientation of precipitates, providing valuable insights into the material's strengthening mechanisms.

X-ray Diffraction (XRD) for Phase Quantification

XRD is a non-destructive technique used to identify and quantify crystalline phases in 718 sheet. It can provide information about the volume fraction of different phases, which is crucial for understanding the material's overall properties and heat treatment effectiveness.

Hardness Testing Methods for 718 Sheet

Rockwell Hardness Testing

Rockwell hardness testing is a widely used method for evaluating the hardness of 718 sheet. It involves applying a load to the material surface using a diamond cone or hardened steel ball indenter. The depth of indentation is measured to determine the hardness value. For 718 sheet, the Rockwell C scale is typically used.

Vickers Hardness Testing

Vickers hardness testing is another common method, particularly useful for measuring the hardness of thin sheets or small areas. It uses a diamond pyramid indenter and measures the size of the resulting indentation to calculate hardness. This method provides high accuracy and is suitable for a wide range of hardness values.

Microhardness Testing for Local Property Evaluation

Microhardness testing is valuable for evaluating local variations in hardness across the 718 sheet. This technique uses very small loads and can measure hardness at specific locations within grains or at grain boundaries. It's particularly useful for studying the effects of heat treatment or processing on the material's properties.

Conclusion

Testing the 718 sheet for grain size, precipitate phases, and hardness is essential for ensuring its quality and performance in demanding applications. By employing a combination of optical microscopy, electron microscopy, and hardness testing techniques, manufacturers and end-users can gain a comprehensive understanding of the material's microstructure and mechanical properties. This knowledge is crucial for optimizing heat treatments, predicting material behavior, and ensuring the reliability of components made from 718 sheet in critical industries such as aerospace and energy. As material science continues to advance, these testing methods will evolve, providing even more precise and insightful data to drive innovation in high-performance alloy development and application.

FAQs

What is the typical grain size range for 718 sheet?

The grain size of 718 sheet typically ranges from ASTM 4 to 8, depending on processing conditions and heat treatment.

How does heat treatment affect the precipitate phases in 718 sheet?

Heat treatment can significantly influence the size, distribution, and volume fraction of precipitate phases, particularly γ' and γ", which are crucial for the alloy's strength.

What is the average hardness range for 718 sheet?

The hardness of 718 sheet typically ranges from 36 to 45 HRC (Rockwell C) in the fully heat-treated condition.

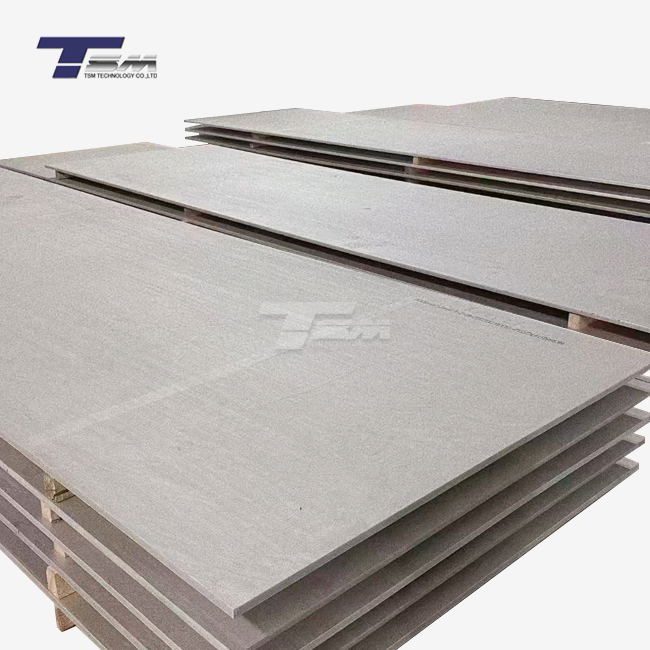

Why Choose TSM Technology for Your 718 Sheet Needs?

TSM Technology stands out as a premier manufacturer and supplier of high-quality 718 sheet. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure unparalleled quality and consistency in every product. Our 718 sheet meets stringent industry standards such as ASTM B670, ASME SB670, and AMS 5596. We offer customization options, various surface treatments, and provide comprehensive material certification. Choose TSM Technology for a reliable, high-performance 718 sheet that meets your most demanding industrial applications. For inquiries or to request a free sample, please contact us at info@tsmnialloy.com.

References

ASTM International. "ASTM E112-13: Standard Test Methods for Determining Average Grain Size." West Conshohocken, PA: ASTM International, 2013.

Schirra, J. J., et al. "Effect of microstructure (and heat treatment) on the 649°C properties of advanced PM superalloy disk materials." Superalloys 2004 (2004): 341-350.

Azadian, S., et al. "Delta phase precipitation in Inconel 718." Materials Characterization 53.1 (2004): 7-16.

Kulawik, K., et al. "Electron microscopy and X-ray diffraction studies of Inconel 718 superalloy." Materials Science and Engineering: A 556 (2012): 267-273.

ASTM International. "ASTM E18-20: Standard Test Methods for Rockwell Hardness of Metallic Materials." West Conshohocken, PA: ASTM International, 2020.

Callister, William D., and David G. Rethwisch. Materials science and engineering: an introduction. Vol. 9. New York: Wiley, 2018.