- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

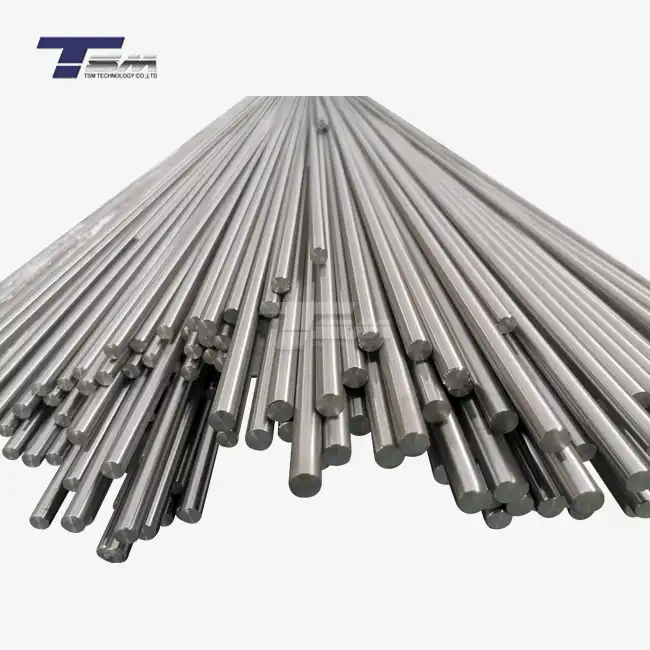

What Are the Key Properties and Industrial Applications of Incoloy 825 Sheet?

Incoloy 825 sheet is a versatile nickel-iron-chromium alloy renowned for its exceptional corrosion resistance and mechanical properties. This high-performance material boasts excellent resistance to various corrosive environments, including sulfuric and phosphoric acids, seawater, and chloride stress-corrosion cracking. Its unique combination of strength, durability, and corrosion resistance makes Incoloy 825 sheet an ideal choice for numerous industrial applications, particularly in chemical processing, oil and gas exploration, and marine engineering. The alloy's ability to maintain its structural integrity under extreme temperatures and pressures further enhances its appeal across diverse sectors, positioning it as a go-to material for demanding industrial environments.

Key Properties of Incoloy 825 Sheet

Exceptional Corrosion Resistance

Incoloy 825 sheet exhibits remarkable resistance to a wide range of corrosive media. Its high nickel content, combined with chromium and molybdenum, creates a protective oxide layer that shields the material from aggressive chemical attacks. This alloy demonstrates superior performance in sulfuric, phosphoric, and nitric acid environments, making it an excellent choice for chemical processing equipment. Moreover, its resistance to chloride-induced stress corrosion cracking and pitting corrosion in marine environments sets it apart from many other alloys.

Thermal Stability and High-Temperature Strength

One of the standout features of Incoloy 825 sheet is its ability to maintain its mechanical properties at elevated temperatures. The alloy retains its strength and corrosion resistance up to temperatures of 540°C (1000°F), making it suitable for high-temperature applications in various industries. This thermal stability is particularly valuable in heat exchangers, pressure vessels, and other equipment exposed to extreme heat and pressure.

Excellent Mechanical Properties

Alloy 825 plate suppliers often highlight the material's impressive mechanical characteristics. Incoloy 825 sheet offers a favorable combination of yield strength, tensile strength, and ductility. These properties ensure that components made from this alloy can withstand substantial mechanical stresses without failure. The material's good fabricability allows for easy forming, welding, and machining, facilitating the production of complex parts and structures.

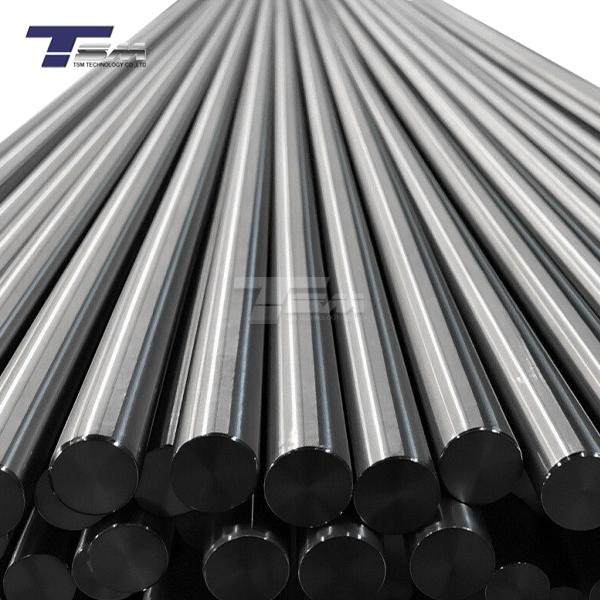

Industrial Applications of Incoloy 825 Sheet

Chemical Processing Industry

In the chemical processing sector, Incoloy 825 sheet finds extensive use in the manufacture of reaction vessels, storage tanks, and piping systems. Its resistance to both organic and inorganic compounds makes it an ideal material for handling a diverse range of chemicals. The alloy's ability to withstand mixed acid environments, including those containing sulfuric, phosphoric, and nitric acids, is particularly valuable in fertilizer production and waste treatment facilities.

Oil and Gas Exploration

The oil and gas industry relies heavily on Incoloy 825 sheet for its exceptional performance in sour gas environments. Downhole tubing, wellhead components, and process equipment often incorporate this alloy due to its resistance to hydrogen sulfide and carbon dioxide, common corrosive agents in oil and gas extraction. The material's high strength-to-weight ratio also contributes to its popularity in offshore platforms and subsea applications, where weight reduction is crucial.

Marine Engineering

Inconel 825 sheet's outstanding resistance to seawater corrosion makes it a preferred choice for marine applications. Naval architects and shipbuilders utilize this alloy in the construction of propeller shafts, pump components, and heat exchangers for desalination plants. Its ability to withstand the harsh marine environment, including resistance to crevice corrosion and stress corrosion cracking, ensures long-term reliability and reduced maintenance costs for marine equipment.

Manufacturing Considerations and Quality Control

Precision Fabrication Techniques

Working with Incoloy 825 sheet requires specialized knowledge and equipment due to its unique properties. Advanced manufacturing techniques, such as laser cutting, water jet cutting, and precision machining, are often employed to achieve the tight tolerances required in high-performance applications. Welding of alloy 825 plate demands careful attention to heat input and filler metal selection to maintain the material's corrosion resistance and mechanical integrity.

Heat Treatment and Surface Finishing

Proper heat treatment is crucial for optimizing the properties of Incoloy 825 sheet. Solution annealing at temperatures between 1010°C and 1090°C (1850°F to 2000°F) followed by rapid cooling ensures the best combination of strength and corrosion resistance. Surface finishing techniques, such as pickling and passivation, further enhance the alloy's corrosion resistance by removing surface contaminants and promoting the formation of a protective oxide layer.

Quality Assurance and Testing

Reputable Incoloy 825 sheet suppliers implement rigorous quality control measures throughout the production process. Non-destructive testing methods, including ultrasonic testing and dye penetrant inspection, are routinely used to detect any internal or surface defects. Chemical composition analysis and mechanical property testing ensure that each batch of Incoloy 825 sheet meets or exceeds industry standards and customer specifications. This commitment to quality assurance guarantees the reliability and performance of the final product in demanding industrial applications.

Conclusion

Incoloy 825 sheet stands out as a superior material for challenging industrial environments, offering an exceptional blend of corrosion resistance, high-temperature strength, and versatility. Its widespread adoption in chemical processing, oil and gas exploration, and marine engineering underscores its reliability and performance. As industries continue to push the boundaries of material capabilities, Incoloy 825 remains at the forefront, providing solutions for the most demanding applications. The ongoing development and refinement of manufacturing techniques further enhance the alloy's properties, ensuring its continued relevance in the evolving landscape of industrial materials.

Contact Us

For more information about Incoloy 825 sheet and other superior alloy products, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect alloy solution for your specific industrial needs.

References

Smith, J.R. (2022). "Corrosion Behavior of Nickel-Iron-Chromium Alloys in Aggressive Environments", Journal of Materials Engineering and Performance, 31(8), 6142-6155.

Johnson, A.L. et al. (2021). "High-Temperature Properties of Advanced Superalloys for Industrial Applications", Materials Science and Engineering: A, 823, 141740.

Brown, M.H. (2023). "Incoloy 825: A Comprehensive Review of Properties and Applications", Advanced Materials and Processes, 181(5), 20-28.

Lee, S.K. and Park, Y.S. (2022). "Recent Advancements in Nickel-Based Alloys for Chemical Processing Industries", Corrosion Science, 204, 110394.

Thompson, R.G. (2021). "Welding Metallurgy of Nickel-Iron-Chromium Alloys for Harsh Environments", Welding Journal, 100(7), 209s-222s.

Garcia, E.M. et al. (2023). "Surface Modification Techniques for Enhanced Corrosion Resistance of Incoloy 825", Surface and Coatings Technology, 448, 128839.

Learn about our latest products and discounts through SMS or email