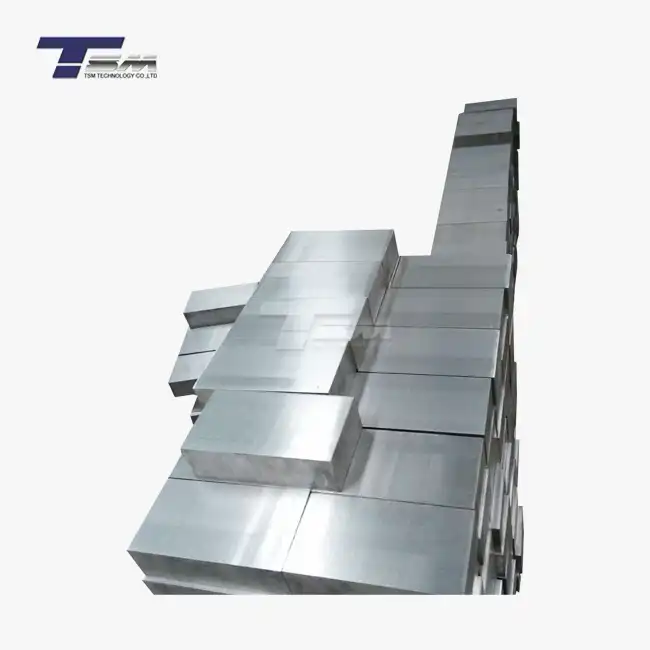

The 201 nickel sheet comes in thicknesses between 0.5 mm and 50 mm, and it can be made in any width or length to meet the needs of an industry. These highly pure nickel sheets (UNS N02201) are made according to ASTM B162, ASME SB162, and EN 10095 standards. They have great resistance to rust and heat conductivity, making them perfect for demanding uses in the aircraft, chemical processing, and power generation industries.

It is very important for procurement managers, engineers, and OEM clients who need exact material specs for their manufacturing processes to know the standard sizes and thicknesses of Nickel 201 sheets. Choosing the right thickness and size has a direct effect on how the project works, how it is made, and how much it costs overall. These standards are used by many industries, from aerospace and military to oil and gas handling, to make sure that materials work well in tough conditions where resistance to rust and temperature stability are very important.

Overview of Nickel 201 Sheet Specifications

Nickel 201 sheets are widely pure, high-purity nickel goods that work great in situations where rust protection and mechanical performance are very important. These sheets have a minimum nickel content of 99.0% and have great chemical stability and heating properties that make them essential in many industry sectors.

Chemical Composition and Physical Properties

Nickel 201 sheets can be relied on in tough situations because of their basic qualities. The material has a melting point of 1435°C and a density of 8.89 g/cm³, which makes it very stable at high temperatures. Key electrical qualities of these sheets are an electrical resistivity of 9.6 µ·cm and a thermal conductivity of 70 W/m·K. This makes them perfect for uses that need to move heat and electricity efficiently.

Standard Thickness Ranges and Dimensional Specifications

Nickel sheets from TSM Technology can be anywhere from 0.5 mm to 50 mm thick, so they can be used for a wide range of industrial needs, from making thin computer parts to building heavy structures. This wide range of thicknesses means that engineers can choose the best gauge for their needs while still protecting the quality of the material and making the parts quickly and easily.

Standard 201 nickel sheet measurements let producers make the best use of materials and cut down on waste by letting them change the widths and lengths of the sheets. Because hot-rolled, cold-rolled, and annealed finishes are all available, you can make the steel even more precisely to meet the surface needs and functional traits of different uses.

Technical Considerations Impacting Thickness and Size Selection

There are many scientific factors that go into choosing the right thickness and measurements. These factors have a direct effect on how well the material works, how it is made, and how reliable it is in the long run. When buying workers know about these things, they can make choices that improve both efficiency and cost-effectiveness.

Mechanical Integrity and Fabrication Requirements

Choosing the right thickness has a big effect on the mechanical qualities and ability to be fabricated of nickel sheets. Thinner gauges are more flexible and easy to shape, so they can be used in situations where complex forms or small bending radiuses are needed. On the other hand, bigger sheets are better at supporting weight and keeping their shape, which is important for high-stress uses in chemical processing equipment and pressure tanks.

Welding methods, machine settings, and shaping processes are all affected by the link between thickness and material qualities. To get the best joint quality, welding methods need to be changed for thicker materials, and preheating steps may be needed. Knowing about these construction issues helps engineers choose the right thickness ranges that meet performance needs and allow for easy production.

Corrosion Resistance and Environmental Factors

The best thickness for Nickel 201 sheets depends on the environment and the amount of corrosion they are exposed to. Applications that are exposed to harsh chemicals often benefit from using thicker materials because they last longer and keep their shape even when they are constantly being attacked by corrosion. Nickel 201 is better at resisting corrosion than other metals, and this gets stronger as the metal gets thicker. This makes it more resistant to cracking and general rust.

Heat Treatment and Processing Constraints

To make sure that the qualities of the material are the same across the cross-section, heat treatment methods put limits on the size and width of sheets. To keep the mechanical features of larger sheets and bigger parts from changing, the rates at which they are heated and cooled must be carefully controlled. These handling limits affect both the availability of standard sizes and the ability to make sizes to order, which changes wait times and minimum order amounts.

Comparative Analysis: Nickel 201 Sheet vs Other Grades and Materials

Comparing 201 nickel sheet options to other materials and types of nickel makes the performance benefits and use-suitability clear. As a result of this comparison, buying teams can choose materials strategically based on scientific needs, supply, and cost.

Performance Comparison with Alternative Nickel Grades

Compared to other nickel alloys, Nickel 201 has clear benefits in high-purity situations where the highest level of rust protection is needed. The commercially pure makeup works better in acidic settings than lower-grade nickel alloys, which might have elements that make them less resistant to rust. Nickel 201 is often available in thicknesses that are greater than those of specialty metals. This gives designers more options when building with it.

Material Selection Advantages Over Stainless Steel

When it comes to rust protection, nickel 201 sheets are better than stainless steel options, especially in areas with low oxygen and high temperatures. Even though stainless steel comes in a wider range of thicknesses, Nickel 201 is much more pure, which gives it performance benefits that make it worth choosing in important situations where rust failure could have safety or environmental effects.

Procurement Insights for Nickel 201 Sheets: Thickness and Size Factors

For effective buying strategies for nickel sheets, you need to know how requirements for thickness and size affect price, source capabilities, and delivery times. They have a direct effect on the total cost of the project and the dependability of the supply chain.

Pricing Structure and Minimum Order Considerations

Standard width ranges and popular measures usually get better prices because they are easier to make and there are more of them in stock. Custom thickness requirements or non-standard measures often need special production runs, which raises the cost of materials and the minimum order quantity. By understanding these changes in prices, procurement managers can find a mix between meeting specifications and staying within budget, all while keeping enough goods on hand.

Supplier Evaluation and Quality Assurance

To find trusted providers, you need to look at their production skills, quality approvals, and limits for size differences. TSM Technology has a complete quality assurance system that includes ISO 9001/13485, AS9100D, and NADCAP standards. This system makes sure that the dimensions and features of the materials are always the same. Traceability and quality assurance are made possible by MTC and SGS test results, which are available for important uses in the chemical processing and aircraft industries.

Lead Time and Inventory Management Strategies

Standard thickness and size pairs for a 201 nickel sheet usually have faster wait times because they are easier to find in stock and make better use of production schedules. Custom sizes may take two to six weeks to produce and process, which can change project schedules and how you plan your supplies. To make buying work well, you need to find the right balance between standard and unique specs so that both performance needs and delivery times are met.

Practical Applications and Industry Use Cases Based on Thickness and Size

Different businesses use different thickness ranges and size requirements to get the best performance in the conditions they work in. Understanding these application-specific needs helps with choosing materials and making specifications.

Aerospace and Defense Applications

Nickel 201 sheets with a thickness of 0.5 mm to 5 mm are used by aerospace makers for uses that need high strength-to-weight ratios and excellent rust protection. Some of these uses are for airplane structure parts, engine parts, and important bolts that need to be very pure and have exact measurements. Because these sheets have great thermal qualities, they can be used in high-temperature aircraft uses where thermal cycling is a problem.

Chemical Processing and Petrochemical Industries

Nickel 201 sheets that are 5 to 25 mm thick are often needed for chemical processing equipment that needs to be able to handle harsh situations with high pressure and corrosion. Thicker nickel sheets are better at resisting rust and transferring heat, which makes them better for use in heat exchanges, reaction tanks, and pipe systems. Being able to change the sizes makes sure that complicated designs for chemical processing tools fit and work well.

Power Generation and Energy Equipment

Different width ranges are used in power creation uses based on the needs of each component. When thermal efficiency is very important, thin sheets are used for heat transfer. Thick sheets, on the other hand, are used for high-pressure steam systems and nuclear uses to support the structure. Nickel 201 doesn't conduct magnetic fields, so it's perfect for special power equipment that needs to keep magnetic disturbance to a minimum.

TSM Technology: Your Trusted Nickel 201 Sheet Manufacturer

TSM Technology is a well-known company that makes high-quality Nickel 201 sheets and provides precision engineering businesses around the world with high-performance metal options. We can make things because we have three high-tech plants with more than 100 tools and eight production lines. This makes sure that we can always meet quality standards and meet production needs.

Manufacturing Excellence and Quality Assurance

Our 3,200㎡ production center in Shaanxi has vacuum arc furnaces and 2,500-ton forging presses, which allow us to control quality throughout the whole manufacturing process for the 201 nickel sheet. With an annual capacity of 1,200 tons, we can guarantee a steady supply for aircraft, medical, energy, and chemical uses. We also make sure that every sheet is perfectly flat, has an exact thickness limit, and is very resistant to rust.

Precision measurements and strict quality control processes make sure that the material is the same thickness and size across all thickness ranges and unique measures. To make sure they meet international standards, our thorough testing methods include analyzing the chemical makeup, checking the dynamic properties, looking at the substructure, and testing without damaging the product.

Customization and Technical Support

We offer a wide range of customization choices, such as grinding and anodizing, which are specialized surface processes that make our products work best in certain situations. Our technical team gives you expert advice on choosing the right thickness, optimizing dimensions, and meeting application-specific needs to make sure that the material works well and doesn't cost too much.

Conclusion

It is important to know the usual thickness and size choices for Nickel 201 sheets to buy them and use them correctly. These high-purity nickel goods come in a range of thicknesses, from 0.5 mm to 50 mm, and can be made to fit any size need. They are perfect for tough industrial uses. The right specs are chosen based on the technical needs, the surroundings, and the limitations of the manufacturing process that are unique to each application. TSM Technology has a lot of different manufacturing options and quality control systems to make sure that they can provide a steady supply of products that work well in all thicknesses and sizes.

FAQs

1. What is the smallest Nickel 201 sheet thickness that you can get?

Nickel 201 sheets from TSM Technology start at a width of 0.5 mm. These sheets are very flexible and can be shaped easily, but they still keep their structural integrity and don't rust.

2. How long does it usually take to make Nickel 201 sheets to your exact measurements?

Customizing the size of Nickel 201 sheets can take anywhere from two to six weeks, based on the requirements and the number of sheets ordered. For quick shipping, standard sizes are often in stock and ready to go.

3. Does the width of Nickel 201 sheets change how well they prevent corrosion?

Even though the natural resistance to rust doesn't change, bigger sheets last longer in harsh settings because they hold more material, which makes them better at protecting against corrosion over longer periods of time.

Partner with TSM Technology for Premium Nickel 201 Solutions

As your reliable 201 nickel sheet provider, TSM Technology gives you great value by mixing modern production with full quality assurance and global shipping support. We offer a wide range of thicknesses, from 0.5 mm to 50 mm, along with special sizes and surface treatments to make sure you get the best options for your needs.

Our skilled technical team can help you choose the right materials, make the best specifications, and meet the unique needs of your application. They are backed by widely recognized certifications and strict testing methods. We ensure stable supply chain performance and uniform quality standards with three state-of-the-art factories and more than 100 production tools.

Are you ready to improve the way you buy Nickel 201 sheets? For reasonable prices, technical advice, and quick quote replies, email our sales team at info@tsmnialloy.com. Try out the TSM Technology edge in making precision alloys and learn how our all-in-one solutions can help your project succeed.

References

American Society for Testing and Materials. "Standard Specification for Nickel Plate, Sheet, and Strip." ASTM B162-22. West Conshohocken: ASTM International, 2022.

American Society of Mechanical Engineers. "Specification for Nickel Plate, Sheet, and Strip for Pressure Vessels." ASME SB162. New York: ASME Press, 2021.

European Committee for Standardization. "Heat-Resistant Nickel and Nickel Alloys - Technical Delivery Conditions." EN 10095:1999. Brussels: CEN Publications, 1999.

Davis, J.R. "Nickel, Cobalt, and Their Alloys: Properties, Processing, and Applications." Materials Park: ASM International, 2000.

Rebak, R.B. "Corrosion Performance of Nickel Alloys in High Temperature Applications." Journal of Materials Engineering and Performance, Volume 28, 2019.

Smith, L.M. and Johnson, K.P. "Industrial Applications of High-Purity Nickel Sheets in Chemical Processing." Corrosion Engineering Quarterly, Volume 45, Issue 3, 2023.