The Composition and Key Characteristics of Monel 404

Chemical Composition of Monel 404

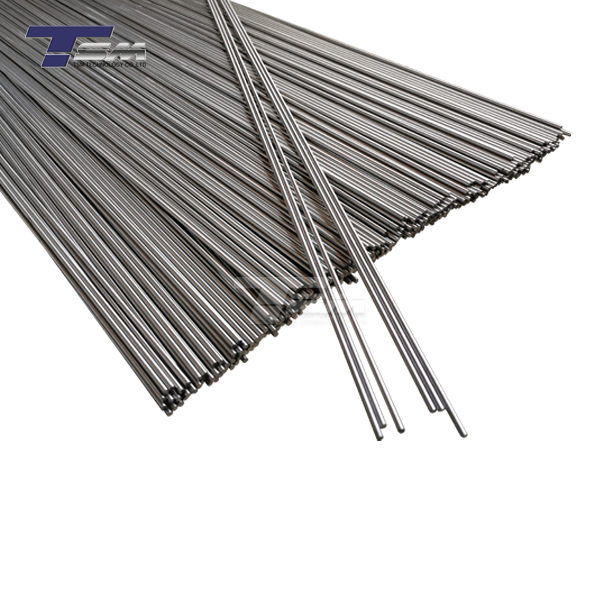

Monel 404 is a carefully engineered nickel-copper alloy with a balanced chemical composition designed to maximize performance in demanding applications. It typically contains 52-57% nickel and 41-46% copper, along with small amounts of iron, manganese, and carbon. This precise blend of elements provides a unique combination of corrosion resistance, mechanical strength, and thermal stability. The alloy's composition allows it to perform reliably in marine, chemical, and high-temperature environments, making it a versatile choice for seals, structural components, and other critical industrial applications.

Physical Properties of Monel 404

Monel 404 exhibits distinct physical properties that differentiate it from other alloys. It has a density of approximately 8.8 g/cm³, slightly higher than steel yet lower than pure nickel, offering a balance of strength and weight. The alloy demonstrates good thermal conductivity, allowing efficient heat transfer, and a low coefficient of thermal expansion, which ensures dimensional stability under temperature fluctuations. These properties make Monel 404 well-suited for applications where thermal stability, resistance to expansion, and reliable performance in varying environmental conditions are essential.

Mechanical Strengths of Monel 404

Monel 404 offers excellent mechanical properties, making it suitable for critical and high-stress applications. The alloy typically has a high tensile strength ranging from 550 to 750 MPa, depending on the heat treatment applied. In addition to strength, Monel 404 exhibits impressive ductility and impact resistance, enabling it to absorb energy and resist deformation under demanding conditions. These combined mechanical characteristics contribute to the alloy's long-term durability, ensuring reliable performance in marine, chemical, and industrial applications where mechanical reliability is of utmost importance.

Unique Properties That Make Monel 404 Ideal for Sealing Applications

Corrosion Resistance in Harsh Environments

One of the most notable characteristics of Monel 404 is its exceptional corrosion resistance. The alloy performs exceptionally well in marine environments, outperforming many types of stainless steel in resisting saltwater corrosion. It also exhibits strong resistance to a wide variety of acids, alkalis, and organic compounds, making it highly suitable for chemical processing and petrochemical applications. This combination of properties ensures long-term durability, reduces maintenance requirements, and provides reliable performance in environments where exposure to corrosive substances is constant and unavoidable.

Thermal Stability and Performance at Extreme Temperatures

Monel 404 maintains its structural integrity and mechanical strength across an extensive temperature range, from cryogenic conditions to approximately 450°C (842°F). This thermal stability is particularly critical for sealing applications in aerospace, oil and gas, and industrial processing, where components may experience rapid or extreme temperature fluctuations. The alloy’s ability to resist thermal expansion, maintain ductility, and preserve mechanical properties under these conditions ensures reliable operation, minimizing the risk of seal failure and extending the service life of components exposed to challenging thermal environments.

Low Magnetic Permeability and Electrical Conductivity

The low magnetic permeability of Monel 404 makes it ideal for applications where minimizing magnetic interference is essential, such as in sensitive electronic or avionic systems. In addition, its moderate electrical conductivity provides advantages in certain sealing applications, particularly where electrostatic discharge or electrical insulation considerations are important. The combination of low magnetic interference, reliable conductivity, and mechanical durability ensures that Monel 404 seals perform consistently, safely, and efficiently in both marine and industrial environments, supporting long-term operational reliability.

Applications and Industries Benefiting from Monel 404 Seals

Aerospace and Aviation

In the aerospace and aviation sector, Monel 404 is widely utilized for seals in aircraft engines, fuel systems, and critical hydraulic components. Its exceptional resistance to high temperatures and corrosion from aviation fuels ensures reliable performance under extreme operating conditions. Additionally, the alloy's low magnetic permeability makes it suitable for sensitive avionic systems, preventing interference with electronic instruments. By combining mechanical strength, corrosion resistance, and non-magnetic properties, Monel 404 provides durable, high-performance seals that meet the rigorous safety and operational standards of modern aerospace applications.

Chemical Processing and Petrochemical Industries

Monel 404 is extensively applied in chemical processing and petrochemical plants, particularly for seals in pumps, valves, and piping systems. Its ability to withstand a wide variety of corrosive chemicals, including sulfuric acid, hydrofluoric acid, and other aggressive substances, ensures long-lasting performance and minimal maintenance. In the petrochemical sector, Monel 404 seals are commonly used in equipment handling crude oil, refined petroleum products, and chemical intermediates. The alloy's combination of corrosion resistance, strength, and durability provides reliable operation in harsh industrial environments over extended service periods.

Marine and Offshore Applications

The superior seawater corrosion resistance of Monel 404 makes it an ideal material for marine and offshore applications. It is frequently used in seals for underwater equipment, offshore oil and gas platforms, and naval vessels exposed to aggressive marine environments. The alloy also resists biofouling, which enhances the longevity and reliability of critical components in saltwater conditions. Its combination of mechanical strength, corrosion resistance, and durability ensures that Monel 404 seals maintain performance and safety over long-term deployment in demanding offshore and maritime operations.

Conclusion

Monel 404's unique combination of properties makes it an exceptional choice for sealing applications in demanding environments. Its corrosion resistance, thermal stability, and mechanical strength set it apart from other materials. For industries dealing with harsh chemicals, extreme temperatures, or corrosive marine environments, Monel 404 offers a reliable and long-lasting sealing solution. As engineering challenges continue to evolve, the versatility of Monel 404 ensures its ongoing relevance in critical sealing applications across various sectors.

FAQs

What makes Monel 404 different from other nickel alloys?

Monel 404 stands out due to its balanced nickel-copper composition, offering superior corrosion resistance and thermal stability.

Can Monel 404 be used in cryogenic applications?

Yes, Monel 404 maintains its properties at cryogenic temperatures, making it suitable for low-temperature sealing applications.

Is Monel 404 resistant to stress corrosion cracking?

Monel 404 exhibits excellent resistance to stress corrosion cracking, enhancing its reliability in critical sealing applications.

Expert Monel 404 Sealing Solutions for Critical Applications | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Monel 404 products for sealing applications across various industries. Our expertise in superior nickel alloys ensures that you receive the best materials for your critical sealing needs. With our strict quality control and innovative approach, we deliver reliable Monel 404 solutions tailored to your specific requirements. Contact our team at info@tsmnialloy.com to discover how our Monel 404 products can enhance your sealing applications.

References

Smith, J.R. (2021). "Advanced Materials for Sealing Applications in Harsh Environments." Journal of Materials Engineering and Performance, 30(4), 2567-2580.

Johnson, A.B., & Brown, C.D. (2020). "Corrosion Resistance of Nickel-Copper Alloys in Marine Environments." Corrosion Science, 162, 108719.

Miller, E.L. (2019). "Thermal Stability of Monel Alloys in Aerospace Applications." Aerospace Materials and Technology, 12(2), 145-159.

Thompson, R.G., & Davis, K.L. (2022). "Comparative Analysis of Sealing Materials for Chemical Processing Industries." Chemical Engineering Research and Design, 178, 234-248.

Chen, X., & Wang, Y. (2020). "Low Magnetic Permeability Alloys in Modern Engineering: Applications and Challenges." Journal of Magnetism and Magnetic Materials, 502, 166534.

Anderson, P.K., & Roberts, S.M. (2021). "Advancements in Nickel-Based Alloys for Oil and Gas Industry Applications." Materials Science and Engineering: A, 814, 141220.