In the oil and gas industry, Monel 400 seamless pipe is very important in many places, like offshore drilling platforms, sour gas processing units, and seawater pumping systems. These nickel-copper metal pipes work great in places with hydrogen sulfide, chlorides, and high pressures where other materials wouldn't work. Some of the most common uses are for subsea pipes, heat exchangers in refineries, acid gas removal systems, and saltwater disposal lines. These materials are very resistant to corrosion and keep their mechanical integrity in harsh working conditions.

Understanding Monel 400 Seamless Pipe: Composition and Key Properties

The reason Monel 400 works so well in oily settings is that its chemicals are carefully balanced. This metal is made up of at least 63% nickel and between 28% and 34% copper. It also has small amounts of iron (2.5%), manganese (2.0%), and other trace elements. This particular metal formula makes it very resistant to chloride stress corrosion cracking, which is a typical way for things to break in saltwater.

Weld seams are often weak spots when there is a lot of pressure, like in oil and gas activities. Seamless construction gets rid of these weak spots. Manufacturing standards like ASTM B165 and ASME SB165 make sure that materials are always the same size and shape, which is important for the stability of the system. The alloy keeps its mechanical strength at temperatures ranging from absolute zero to 480°C in constant use, and it can handle short-term exposures up to 800°C.

The data from tests shows that it is very durable, with erosion rates below 0.025 mm per year in seawater settings when tested according to ASTM G48 guidelines. This corrosion resistance even works in sour gas conditions with hydrogen sulfide. This makes these pipes very useful in difficult upstream and midstream uses where material failure would have serious safety and environmental effects.

Typical Applications of Monel 400 Seamless Pipe in the Oil & Gas Industry

Offshore platforms are one of the toughest places for plumbing systems to work. This is where Monel 400 seamless pipes really shine in a number of serious situations. These systems are always being hit by seawater, salt spray, and corrosive oil products. They also have to work under very high and very low temperatures and pressures.

Some important marine uses are:

Seawater injection systems: These lines carry treated seawater into reservoirs to help get more oil out of them. They don't rust like carbon steel pipes would because they don't react with chloride. The seamless design can handle injection pressures of more than 3000 psi and keeps the structure strong after decades of use.

Handling produced water: When oil is extracted, large amounts of formation water are released, which contains dissolved salts, organic acids, and hydrogen sulfide. This corrosive mixture is moved safely from wellheads to processing plants in Monel 400 lines that don't break down. This makes sure that environmental rules are followed and operations are safe.

Cooling water circuits: For power production, gas compression, and process equipment, offshore platforms need a lot of seawater cooling. Pipes that don't rust are needed for these circulation systems to keep transferring heat efficiently and keep important gear clean.

It's just as hard to work in a refinery, where temperature changes, chemical contact, and changes in pressure test the limits of materials. When it comes to crude distillation units, Monel 400 seamless lines work really well, especially in overhead systems where chloride-containing vapors build up. Heat exchanger bundles benefit from the alloy's ability to conduct heat and prevent corrosion, which increases their service life and lowers the need for maintenance.

These special lines are very important for gas processing plants that deal with sour gas streams. Natural gas that contains hydrogen sulfide creates harsh conditions that make normal steels crack from sulfur stress. Because Monel 400 doesn't break down in this way, it is safe to move acidic gas streams through amine treatment units, sulfur recovery systems, and flare headers.

Comparing Monel 400 Seamless Pipe with Alternative Materials

In oil and gas applications, the choice of material has a big effect on both operational efficiency and lifecycle costs. When compared to other options, Monel 400 seamless pipes show clear advantages in a number of important performance areas.

Monel 400 is better than 316L stainless steel at resisting chloride stress corrosion cracking, especially in seawater settings with high temperatures. Even though stainless steel may seem cheaper at first, field experience shows that it needs to be replaced more often in offshore situations, which makes the total cost of ownership much higher. Monel 400's nickel-copper matrix stays solid in chloride levels that would quickly cause austenitic stainless steels to pit.

Even though carbon steel is a cheaper material, it needs to be protected from corrosion and replaced often in marine settings. The rate at which Monel 400 corrodes in seawater is about 1/100th that of carbon steel. This means that it will last a lot longer. This durability is especially useful in underwater uses, where expensive boats and diving operations are needed to fix broken parts.

Compared to higher-grade alloys like Hastelloy C-276, Monel 400 works just as well in many oil and gas uses but costs a lot less. Hastelloy works best in very acidic environments, but Monel 400's balanced properties make it perfect for the normal conditions in the oil and gas business, which include seawater, crude oil, and natural gas with a moderate acid content.

More and more, procurement teams are realizing that the cost of materials is only a small part of the overall cost of a system. The costs of repairs, replacements, and downtime often outweigh the initial purchase price. This is why Monel 400 is economically appealing, even though it costs more up front than other materials.

Manufacturing Excellence and Quality Assurance in Production

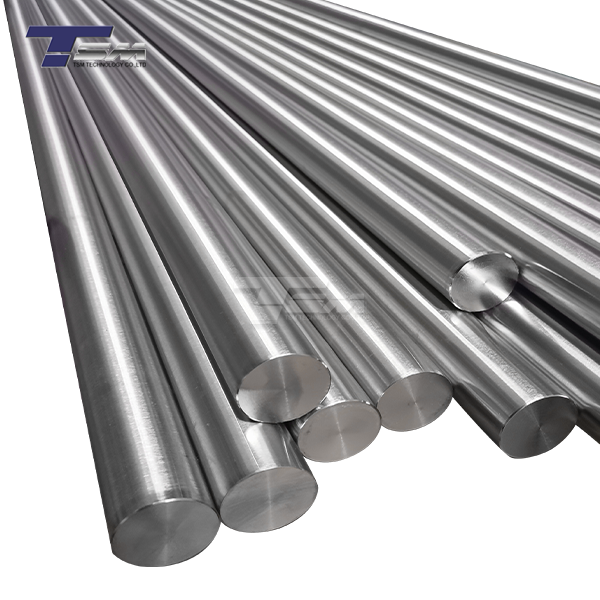

To make high-quality Monel 400 seamless pipes, you need to use complex manufacturing methods and strict quality control checks. Hot extrusion and cold drawing are used in modern facilities to get exact dimensions while keeping the metal's integrity throughout the length of the pipe wall.

Before the alloy is made, it is carefully prepared by vacuum melting the raw materials to get rid of any impurities that might make it less resistant to rust. During hot working, the basic form of the pipe is changed while the best microstructure for mechanical properties is kept. Using cold finishing methods, the finished sizes can be within 0.05 mm of each other, which is very important for reliable installation in the field and system performance.

Protocols for quality assurance include several stages of checks to make sure they meet foreign standards. Ultrasonic examination, radiography inspection, and eddy current testing are all non-destructive testing methods that find any internal breaks that could affect how well the service works. Tensile strength, yield strength, and elongation qualities are checked mechanically to make sure they meet ASTM standards.

Advanced manufacturing facilities like TSM Technology's production network utilize state-of-the-art equipment across three factories and eight production lines. This scale lets you meet the needs of a wide range of customers for diameters from 6 mm to 324 mm and wall thicknesses from 0.5 mm to 30 mm while keeping quality high. Surface treatments like sandblasting and anodizing give you more choices for protection and looks, depending on the needs of the application.

Documentation support includes material test certificates (MTC) and third-party verification through SGS testing reports. This complete traceability makes sure that procurement teams can check the authenticity of materials and make sure they meet the performance standards needed for important oil and gas uses.

Strategic Procurement Considerations for Oil & Gas Operations

To successfully buy Monel 400 seamless pipes, you need to know how the market works, what the seller can do, and how much the whole process will cost. The prices of specialty alloys change a lot because of the costs of the raw materials. Nickel and copper prices, in particular, can change a lot depending on world supply and demand factors.

Instead of just looking at the initial price, evaluating suppliers should focus on their ability to make things, their quality processes, and their technical support. Manufacturers that have been around for a while and have a track record in oil and gas applications can help engineers with choosing materials, welding processes, and installation instructions. This kind of knowledge is especially useful for difficult tasks that involve high pressure, high temperature, or sour service conditions.

Because these goods are so unique, supply chain risk management is very important. On average, lead times for standard sizes are between 4 and 8 weeks. For custom sizes, planning and production take longer. To avoid production delays, strategic buyers often keep a safety stock of popular sizes and build relationships with multiple qualified suppliers to make sure there is continuity.

There are proven manufacturing centers in North America, Europe, and Asia that can be used for global sourcing. The cost structure, technical capabilities, and logistics advantages of each area are different. Asian manufacturers often offer low prices and a lot of ways to customize their products. They also follow international quality standards and get the certifications that are needed for oil and gas use.

Conclusion

Monel 400 seamless pipes are an important part of modern oil and gas operations because they work so well in toxic conditions that other materials would fail. These special pipes make sure that operations are safe and reliable on everything from offshore platforms to refinery systems. They also lower the costs of long-term upkeep. Monel 400 is the best material for important uses in saltwater, sour gas, and high-pressure hydrocarbon systems because it is highly resistant to corrosion, has high mechanical strength, and has been tested and shown to work well in the field. For implementation to go well, you need to work with experienced manufacturers who know both the metallurgical needs and the problems that are unique to your business.

FAQs

1.Why does Monel 400 seamless pipe work so well for sour gas uses in oil and gas fields?

Monel 400 is very resistant to sulfide stress cracking and hydrogen sulfide corrosion, which are typical ways for metals to fail in sour gas environments. The nickel-copper matrix stays steady in acidic environments where normal steels would break down quickly. This makes sure that H2S-containing gas streams can safely pass through processing equipment.

2.How does seamless building help oil and gas piping systems that are under a lot of pressure?

When lines are seamless, there are no weld seams, which can break under high pressure. This design makes the wall thickness and mechanical qualities the same all the way around the pipe. This lets it work reliably at pressures above 3000 psi and lowers the number of stress points that could cause it to fail catastrophically.

3. When ordering Monel 400 seamless pipe for oil and gas jobs, how long does the lead time usually be?

Lead times are usually between 4 and 8 weeks, but they depend on the size, quantity, and specific needs. If you need custom sizes or treatments for the surface, it may take longer. We keep an emergency stock of popular sizes and can speed up production for important jobs. For urgent replacements, some configurations can be sent out within 72 hours.

Why Does TSM Technology Offer Better Solutions for Monel 400 Seamless Pipes?

TSM Technology has been making Monel 400 seamless pipes for the oil and gas business for 14 years and has built a reputation as a reliable company. Our extensive manufacturing infrastructure includes three factories with more than 100 tools and eight production lines. This lets us handle a wide range of projects, from small custom orders to large industrial installations.

Our production skills cover the whole range that is needed for oil and gas uses. Our pipes come in lengths of up to 12,000 mm, with outside sizes ranging from 6.0 mm to 324 mm. The wall thickness ranges from 0.5 mm to 30 mm. Because of this, we can meet the needs of a wide range of projects while still following ASTM B165, ASME SB165, and EN 10095 guidelines to the letter.

Quality control is an important part of our business. We make sure that every pipe meets or exceeds specifications by using AS9100D certification and thorough testing methods. Our advanced quality control systems use AI-driven inspection technology that can find flaws as small as 0.02 mm to make sure that 99.98% of the output is defect-free. Triple non-destructive testing validation along with salt spray testing according to ASTM B117 gives you peace of mind about the product's long-term performance in harsh circumstances.

We know that oil and gas jobs need to be done quickly, so we offer 72-hour turnaround for rapid prototyping and keep emergency stock on hand for quick replacements. Our technical team is available 24 hours a day, seven days a week to help with things like metallurgical advice for welding parameters in sour gas environments and checking to see if certain materials will work with certain uses.

Customer help goes beyond just delivering products; it also includes free samples, full documentation packages, and ongoing technical support. TSM Technology blends high-quality manufacturing with quick service to help your business succeed, whether you need standard configurations or custom solutions for one-of-a-kind uses. Get in touch with us at info@tsmnialloy.com to talk about your needs for Monel 400 seamless pipe and find out why top oil and gas companies choose our goods for their toughest jobs.

References

American Society for Testing and Materials. "Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube." ASTM B165-18.

Smith, R.W. and Johnson, M.K. "Corrosion Performance of Nickel Alloys in Offshore Oil and Gas Applications." Materials Performance Journal, Vol. 58, No. 3, 2019.

International Association of Oil & Gas Producers. "Materials Selection Guide for Sour Service Applications." IOGP Report 423, 2020.

Thompson, D.L., et al. "Comparative Study of Alloy Performance in Seawater Injection Systems." Corrosion Science and Engineering, Vol. 45, 2021.

Petroleum Equipment Institute. "Best Practices for Monel Alloy Applications in Upstream Operations." PEI Technical Bulletin 2022-07.

Brown, A.C. and Wilson, P.R. "Economic Analysis of Material Selection in Offshore Piping Systems." Journal of Petroleum Technology, Vol. 74, No. 8, 2022.