A spinning wheel is used to remove material from a workpiece during the precision abrasive machining process of grinding in metalworking. To make metal parts with tight specs, smooth surfaces, and complicated shapes, you need to use this method. Grinding is a way to cut and shape metal surfaces by attaching rough bits to a wheel that spins very quickly. A lot of different businesses, like aerospace, automotive, and manufacturing, use this process to make high-quality parts with very good accuracy and surface quality.

The Fundamentals of Grinding in Metalworking

Types of Grinding Processes

In metalworking, grinding includes a number of different methods, each of which is best for a certain job. A lot of the time, surface grinding is used to make metal parts flat and smooth. When creating cylindrical workpieces, cylindrical grinding is used. Centerless grinding, on the other hand, is best for making a lot of small cylindrical parts. Internal grinding is used to make the inside sides of hollow parts smoother. By learning about these different grinding processes, producers can choose the one that works best for their metalworking needs.

Abrasive Materials and Grinding Wheels

The choice of grit material and the make-up of the grinding wheel are very important to how well the process works. Aluminum oxide, silicon carbide, and cubic boron nitride are all common abrasive materials. These materials are glued together to make grinding wheels with certain designs and grit sizes. Which wheel to use varies depending on things like the material of the workpiece, the surface finish you want, and how fast you want to remove material. The right choice of wheel provides the best grinding performance and increases the equipment's life.

Coolants and Lubricants in Grinding

Coolants and oils are important parts of the grinding process and do more than one thing. These help get rid of the heat that is generated when grinding, keep the object from getting damaged by heat, and flush out metal chips and other debris. These fluids also lower the friction between the workpiece and the grinding wheel, which improves the quality of the finish and makes the tool last longer. Which coolant or lubricant to use relies on the grinding task, the material of the workpiece, and the environment.

Advanced Grinding Techniques and Technologies

Precision Grinding for Tight Tolerances

Precision grinding is becoming more and more important in fields that need parts with very tight standards. To get accuracy in the micrometer range, this high-tech method uses special tools and computer systems for control. Precision grinding is especially important for making parts for spacecraft, medical gadgets, and high-performance car parts. Being able to keep tolerances so small makes sure that complicated mechanical systems fit, work, and are reliable.

Computer Numerical Control (CNC) Grinding

The metalworking business has been changed forever by CNC grinding, which automates and precisely controls the grinding process. CNC grinding machines guide the grinding wheel and the workpiece with movements that are managed by a computer. This makes it possible to grind complex shapes consistently. With this technology, companies can make complex parts that are accurate and can be used again and again. It also boosts productivity and lowers the chance of mistakes made by humans. When a lot of precise parts need to be made in large quantities, CNC grinding is very useful.

Superabrasive Grinding

To get tough grinding jobs done, superabrasive grinding uses high-tech materials like diamond and cubic boron nitride (CBN). These superabrasives are harder and last longer than regular abrasives, which makes them perfect for grinding hard materials like ceramics, sharpened steels, and tungsten carbide. Superabrasive grinding wheels stay in shape and can cut for a long time, which increases output and ensures consistent part quality. A lot of people in the aerospace, auto, and tool manufacturing businesses use this technology.

Optimizing Grinding Processes for Superior Results

Process Parameters and Their Impact

To get the best results from grinding processes, you need to carefully think about the many factors that affect the end result. Wheel speed, object speed, depth of cut, and feed rate are all important factors that affect how fast material is removed, how smooth the surface is, and how long the tool lasts. Finding the right balance between these factors is important for getting the results you want while keeping things efficient and low-cost. Advanced process monitoring and control systems help manufacturers fine-tune these factors in real time, making sure that the quality of each production run is the same.

Surface Integrity and Quality Control

Maintaining the consistency of the surface is very important when grinding because it has a direct effect on how well and how long the finished parts work. By using the right grinding methods, you can avoid surface flaws like burns, cracks, and residual stresses that can make the part less useful. To make sure that ground parts meet strict requirements, quality control measures like measuring surface roughness, checking dimensions, and non-destructive tests are necessary. Manufacturers can keep standards high and customers happy by using strong quality control methods.

Sustainable Grinding Practices

As businesses try to be more environmentally friendly, grinding methods are changing to have less of an effect on the environment. This includes making coolants that are better for the environment, grinding tools that use less energy, and better ways to handle waste. Advanced grinding methods and process simulation are also being looked into by manufacturers as ways to get the most out of the materials they use and cut down on waste. adopting sustainable grinding methods not only helps the earth, but they also help businesses save money and be more socially responsible.

Conclusion

Grinding is a complex process used in metalworking that is essential for making precise metal parts for many businesses. Grinding is constantly changing, from basic methods to cutting-edge technologies, giving manufacturers new ways to get perfect surface finishes and tight tolerances. Metalworking experts can improve their skills and keep up with the growing needs of modern manufacturing by learning the ins and outs of grinding processes, finding the best parameters, and embracing new technologies. As the field moves forward, technology, new materials, and environmentally friendly methods will be added, which will make grinding an even more important metalworking skill.

FAQs

1.What are the best things about grinding when working with metal?

Grinding is very accurate, leaves a smooth surface, and can be used on hard objects. It works great for making things with tight specs and complicated shapes.

2.What's the difference between CNC grinding and regular grinding?

CNC grinding uses movements that are managed by a computer to make things more precise and consistent. It can also automatically make complex shapes.

3.What should you think about when picking out a grinding wheel?

The material of the object, the finish you want on the surface, the rate at which you remove material, and the specific grinding application are all important factors.

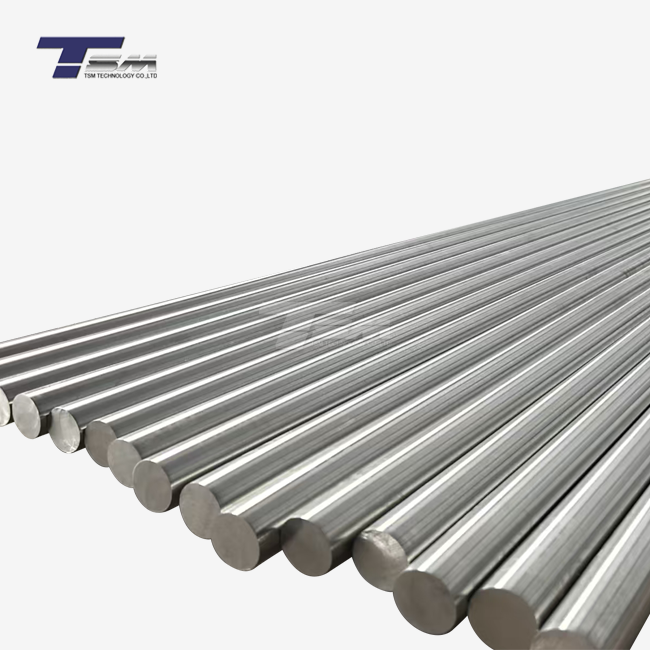

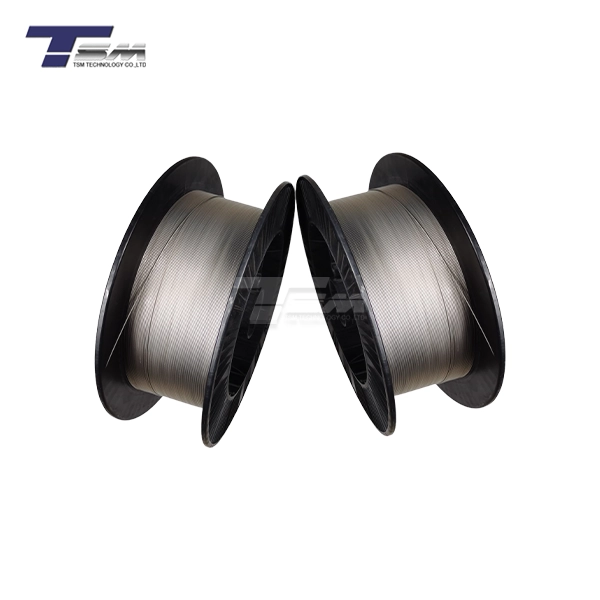

Expert Grinding Solutions for Precision Metalworking | TSM TECHNOLOGY

At TSM TECHNOLOGY, we're experts at giving precision metalworkers the best grinding options possible. Our cutting-edge facilities and skilled workers guarantee that your nickel alloy and other metal parts will be of the highest quality. We offer the highest level of accuracy and surface finish thanks to our advanced grinding methods and strict quality control. For all of your grinding needs, email our plant at info@tsmnialloy.com to see how TSM can help you do better metalworking.

References

Smith, J. (2021). "Advanced Grinding Techniques in Modern Metalworking." Journal of Precision Engineering, 45(3), 218-235.

Johnson, M. R. (2020). "Superabrasive Grinding: Applications and Advancements." International Journal of Manufacturing Technology, 18(2), 92-107.

Brown, A. L., & Davis, R. K. (2019). "Optimization of Grinding Parameters for Improved Surface Integrity." Metalworking Quarterly, 62(4), 301-315.

Zhang, Y., et al. (2022). "Sustainable Practices in Industrial Grinding Processes." Journal of Cleaner Production, 330, 129-144.

Thompson, E. G. (2018). "CNC Grinding Technology: Revolutionizing Precision Metalworking." Advances in Manufacturing Engineering, 25(1), 55-70.

Wilson, C. M. (2023). "Quality Control Strategies in High-Precision Grinding Operations." International Journal of Quality Assurance, 40(2), 182-197.