- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is Dispersion Strengthening and What are the Dispersion Strengthening Alloys?

Dispersion strengthening is a powerful metallurgical technique used to enhance the mechanical properties of metal alloys. This process involves distributing fine particles of a secondary phase throughout the matrix of a metal, resulting in improved strength, hardness, and high-temperature stability. Dispersion-strengthening alloys are materials that have undergone this process, exhibiting superior performance in demanding applications. These alloys typically contain small, evenly dispersed particles of oxides, carbides, or other compounds that impede dislocation movement, thereby increasing the material's overall strength and resistance to deformation at elevated temperatures.

Understanding the Science Behind Dispersion Strengthening

Dispersion strengthening is a cornerstone of modern metallurgy, enabling the creation of materials that can withstand extreme conditions. To truly appreciate its value, we need to explore the mechanisms at play, the role of particles in enhancing strength, and how this technique differs from other strengthening methods.

The Mechanisms of Dispersion Strengthening

At its core, dispersion strengthening involves embedding tiny, stable particles—often oxides or carbides—into a metal matrix. These particles act as obstacles, impeding the movement of dislocations within the metal's crystal lattice. Dislocations are defects in the atomic structure that, when moved, cause plastic deformation. By hindering their motion, the metal becomes significantly stronger and more resistant to deformation, even at elevated temperatures. Unlike other methods that rely on heat treatment or alloying, dispersion strengthening maintains its efficacy at high temperatures, making it ideal for demanding applications.

The Role of Dispersed Particles

The particles used in dispersion strengthening are not just any inclusions - they are meticulously chosen for their stability and compatibility with the base metal. Typically, these particles are oxides, such as yttria or alumina, due to their exceptional thermal stability and insolubility in the metal matrix. Their size, distribution, and volume fraction are critical factors. Smaller, uniformly distributed particles maximize strength by creating a dense network of barriers. This approach is particularly effective in superior alloys, where maintaining mechanical integrity under extreme conditions is paramount.

How Dispersion Strengthening Differs from Other Methods?

To appreciate the uniqueness of dispersion strengthening, it's helpful to contrast it with other strengthening techniques, such as precipitation hardening or solid solution strengthening. Precipitation hardening relies on heat treatment to form coherent precipitates, which can dissolve at high temperatures, reducing effectiveness. Solid solution strengthening, on the other hand, involves dissolving one element into another to distort the lattice, but it often lacks the thermal stability of dispersion strengthening. What sets dispersion strengthening apart is its ability to retain strength at temperatures where other methods falter, making it a preferred choice for high-performance alloys.

Exploring Dispersion Strengthening Alloys and Their Applications

Now that we understand the science, let's turn our attention to the stars of the show: dispersion-strengthened alloys. These materials are engineered to deliver unparalleled performance, and their applications span industries that demand the utmost in reliability and durability. Let's examine the types of alloys, their key properties, and the industries that rely on them.

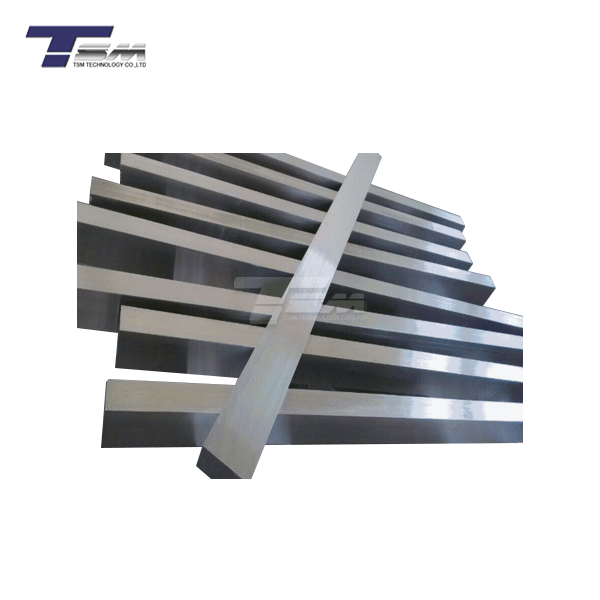

Types of Dispersion Strengthening Alloys

Dispersion-strengthened alloys come in various forms, each tailored to specific needs. Nickel-based superalloys, such as those enhanced with oxide particles, are among the most prominent. These alloys, often referred to as oxide-dispersion-strengthened (ODS) alloys, combine the inherent corrosion resistance and high-temperature strength of nickel with the added benefits of dispersion strengthening. Other examples include copper-based alloys strengthened with alumina particles and iron-based ODS alloys. Each type is designed to excel in specific environments, from corrosive marine settings to the searing heat of turbine engines.

Key Properties of Dispersion-Strengthened Alloys

What makes these alloys so remarkable? Their standout properties include exceptional creep resistance, meaning they resist deformation under prolonged stress at high temperatures. They also exhibit superior fatigue strength, allowing them to endure repeated loading without failure. Additionally, these alloys maintain their mechanical integrity in oxidative and corrosive environments, a crucial trait for applications in harsh conditions. For industries requiring materials that can perform reliably over extended periods, these properties are invaluable, positioning dispersion-strengthened alloys as a cornerstone of advanced engineering.

Industries and Applications Relying on These Alloys

The versatility of dispersion-strengthened alloys makes them indispensable across a range of sectors. In aerospace, they are used in turbine blades and combustion chambers, where temperatures can exceed 1,000°C. The energy sector relies on them for components in gas turbines and nuclear reactors, where durability under thermal stress is non-negotiable. Precision engineering and machine shops also benefit from these materials, crafting components that demand exacting tolerances and longevity. Companies like TSM Technology Co., Ltd., a global leader in supplying superior alloys, play a pivotal role in providing these high-performance materials to meet the needs of such industries.

Innovations and Future Trends in Dispersion-Strengthening Alloys

The world of dispersion strengthening is not static - it's a field of constant innovation, driven by the need for ever-more-capable materials. Advances in manufacturing, emerging alloy compositions, and sustainability considerations are shaping the future of these alloys. Let's explore what's on the horizon.

Advances in Manufacturing Techniques

Producing dispersion-strengthened alloys is no simple feat, but recent advancements are making it more efficient and precise. Techniques like mechanical alloying, where metal powders are blended with oxide particles and then consolidated, have revolutionized the production of ODS alloys. Additive manufacturing, or 3D printing, is also gaining traction, allowing for the creation of complex components with tailored microstructures. These innovations enable manufacturers to achieve finer particle distributions and enhanced material properties, pushing the boundaries of what superior alloys can achieve.

Emerging Alloy Compositions

The quest for better performance is driving the development of new alloy compositions. Researchers are experimenting with novel combinations, such as titanium-based ODS alloys for lightweight applications and cobalt-based alloys for enhanced wear resistance. Hybrid alloys, which combine dispersion strengthening with other methods like precipitation hardening, are also emerging, offering a synergistic boost in performance. These advancements ensure that industries have access to materials that meet increasingly stringent demands, from higher operating temperatures to greater environmental resistance.

Sustainability and the Future of Alloy Development

As industries strive to reduce their environmental footprint, sustainability is becoming a key focus in alloy development. Dispersion-strengthened alloys, with their longevity and resistance to degradation, already contribute to sustainability by reducing the need for frequent replacements. However, efforts are underway to make their production more eco-friendly, such as using recycled materials in mechanical alloying or developing alloys that require less energy to process. Companies like TSM Technology Co., Ltd. are at the forefront of this movement, continuously improving their offerings to align with global sustainability goals while maintaining their reputation for quality and innovation.

Conclusion

Dispersion strengthening is a remarkable technique that has transformed the landscape of advanced materials, enabling the creation of alloys that thrive under the most challenging conditions. From the science of particle reinforcement to the diverse applications of dispersion-strengthened alloys, this field offers endless fascination and potential. As industries continue to push the limits of performance, innovations in manufacturing, alloy compositions, and sustainability will ensure that these materials remain at the cutting edge. Whether you're in aerospace, energy, or precision engineering, understanding the power of these alloys can unlock new possibilities for your projects.

Contact Us

For more information about our superior nickel alloys and special metals, including dispersion-strengthened varieties, please don't hesitate to contact TSM TECHNOLOGY. Our team of experts is ready to assist you in finding the perfect material solution for your specific needs. Reach out today at info@tsmnialloy.com.

References

Smith, J. A., & Brown, T. R. (2019). Advanced Metallurgy: Principles of Dispersion Strengthening in High-Performance Alloys. Materials Science Press.

Lee, H. K., & Patel, M. S. (2021). Oxide-Dispersion-Strengthened Alloys: Applications in Extreme Environments. Engineering Materials Journal.

Garcia, R. E., & Thompson, L. D. (2020). Innovations in Nickel-Based Superalloys: Dispersion Strengthening Techniques. Industrial Metallurgy Review.

Nakamura, Y., & Singh, P. (2018). Mechanical Alloying and Its Impact on Dispersion-Strengthened Materials. Journal of Advanced Manufacturing.

Evans, D. W., & Carter, S. L. (2022). Sustainable Practices in Alloy Development: A Focus on Dispersion Strengthening. Green Engineering Publications.

Kim, S. J., & Alvarez, E. M. (2023). Future Trends in High-Temperature Alloys: Dispersion Strengthening and Beyond. Materials Innovation Digest.

Learn about our latest products and discounts through SMS or email