The Inconel 690 tube is a high-performance nickel-chromium metal tubing option that was made to work with nuclear power. This superalloy has great resistance to rust, great mechanical strength, and amazing longevity in harsh situations like high radiation, harsh chemicals, and temperature cycles. These high-quality tubes are used in steam generator systems and important nuclear parts all over the world, where safety and durability are the most important things.

Understanding Inconel 690 Tube: Specifications and Properties

Nickel-chromium alloy tube is different from other materials because of its unique makeup. Nickel (58% minimum), chromium (28–31%), and iron (9–11%) make up most of Inconel 690 tubes. They meet strict world standards like ASTM B622, ASME SB622, and EN 10095.

Chemical Composition and Mechanical Properties

Figuring out the exact chemicals that make up this superalloy helps you understand why it works so well in nuclear settings. The high nickel content makes it very resistant to rust, and the high chromium rate makes it more resistant to oxidation at high temperatures. The highest carbon amount is kept at 0.05% to stop carbide crystals, which could hurt efficiency.

The strong qualities of the mechanical traits are truly impressive. With a minimum tensile strength of 655 MPa and a minimum yield strength of 275 MPa, these seamless tubes can handle a lot of force without breaking. With a density of 8.19 g/cm³ and a melting point range of 1343–1377°C, it can be used reliably in nuclear uses that need to work at high temperatures.

Manufacturing Standards and Specifications

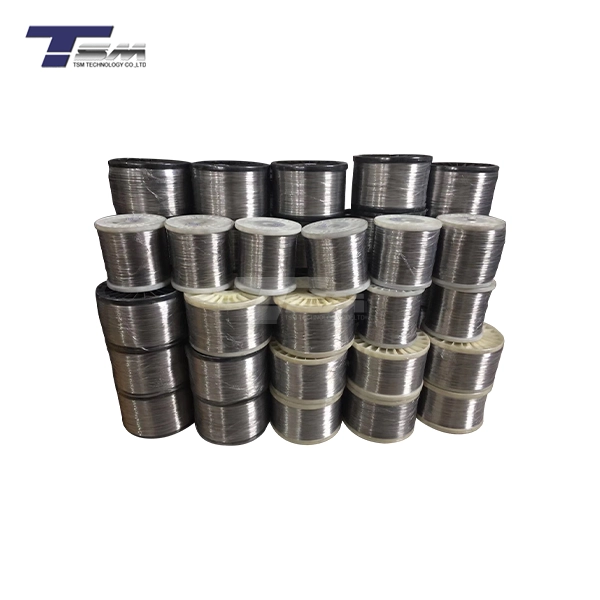

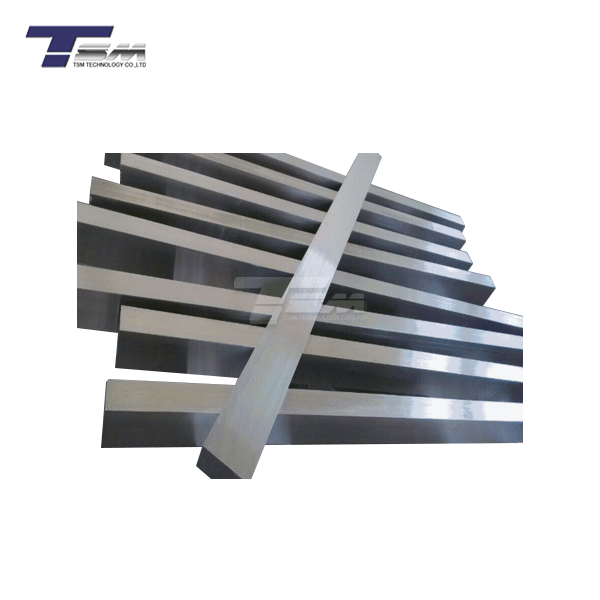

These high-quality tubes are made by TSM Technology with exact control over their dimensions. We can make things with outside sizes from 6.0 mm to 114 mm, wall thicknesses from 0.5 mm to 15 mm, and lengths of up to 15,000 mm. To get the best performance in nuclear settings, the surfaces are treated with grinding, electropolishing, and chemical passivation.

Why Inconel 690 Tubes Are Preferred in Nuclear Plants?

Materials used in nuclear power plants must be able to survive the toughest working conditions and still be completely reliable. When it comes to applications where a material failure could have terrible results, Inconel 690 tube steam generator tubing is the most important one.

Superior Corrosion Resistance in Nuclear Environments

This metal is different from others like Inconel 600 and stainless steel because it is very resistant to stress corrosion cracks. Tubing in nuclear steam engines is exposed to harsh water chemistry, high temperatures, and neutron radiation all at the same time. Nickel-chromium metal tubes stays strong over long periods of service, while other materials often break under these combined loads.

Comparative tests show that some products work much better than others. While Inconel 600 can crack due to primary water stress corrosion, this better alloy is resistant to this failure mechanism thanks to its higher chromium content. The new material is also better at stopping acidic rust and denting, which are typical issues in nuclear steam engines.

Thermal Stability and Radiation Resistance

Extreme changes in temperature and neutron bombardment happen inside nuclear reactors. The quality tubes' stable architecture keeps them from breaking down when exposed to radiation and keeps their flexibility when the temperature changes. Because of this temperature stability, parts will last longer and need less upkeep.

Operational data from nuclear plants around the world shows that this choice of materials made the plants more reliable. Plants that use these tubes say that they can run for longer periods of time without needing to be inspected and that they plug up much less often than tubes made of other alloys.

Manufacturing and Quality Assurance of Inconel 690 Tubes

Modern ways of making things make sure that the quality and dimensions stay the same, which is important for nuclear uses, such as in the production of Inconel 690 tube. Modern production methods are used on all 8 of TSM Technology's production lines to make high-quality superalloy tubes.

Production Process and Technology

The first step in the production process is choosing high-quality raw materials and vacuum freezing them to get rid of any flaws that might affect performance. By carefully controlling the temperature, hot working makes the first tube shape, and cold drawing gets the end measurements very precisely. The annealing process improves the material qualities and reduces any remaining pressures.

Our high-tech building has more than 100 precise machines, such as five-axis machining centers and specialized making tools. This infrastructure makes it possible to keep the standard of production high while keeping the tight limits needed for nuclear uses.

Comprehensive Quality Control Systems

Before delivering a tube, strict quality assurance routines check every part of its performance. Ultrasonic checking, radiography examination, and eddy current testing are all non-destructive testing methods that can find problems inside a product that could shorten its useful life.

Hydrostatic testing is done on each tube to make sure it can handle pressure, and microstructure analysis is done to make sure the right heat treatment was done. Mill Test Certificates (MTC) and SGS test results that confirm the chemical make-up and mechanical qualities make up the full material tracking paperwork. These approvals make sure that nuclear safety standards and government rules are followed.

Procurement Guide for Inconel 690 Tubes: Pricing, Suppliers, and Purchase Tips

To do a good job of buying, you need to know what affects costs and choose skilled sources who can meet nuclear quality standards. The high cost of the materials used to make this superalloy, Inconel 690 tube, is due to its high performance and long service life.

Cost Considerations and Value Analysis

The amount of money needed to buy quality nickel-chromium metal tubes depends on a number of things. Costs are directly affected by size, wall thickness, and production volume. Base material prices are also affected by changes in the nickel and chrome markets. Customized needs and fast delivery times may raise costs, but they are often required for important nuclear uses.

Lifecycle cost study shows that this choice of material is more cost-effective. Even though it costs more up front than options like stainless steel, the longer life and lower upkeep needs save a lot of money in the long run. Nuclear plants say that their running costs have gone down because they are more reliable and don't need to be inspected as often.

Supplier Selection Criteria

To find good Inconel 690 tube providers, you need to carefully look at their credentials and skills. For nuclear uses, sellers must have the right quality standards, such as ISO 9001 and nuclear-specific certificates. Logistics and project timelines are affected by things like the ability to manufacture, the availability of expert help, and the distance between locations.

TSM Technology has been working in the nuclear business for 14 years and has a lot of certifications and quality methods that have been proven to work. Our 50,000▥ plant can offer up to 300 tons of goods every month and can also customize and process them to meet the needs of particular projects.

TSM Technology: Your Trusted Inconel 690 Tube Manufacturer

The TSM Technology company is an expert in high-quality superalloys, such as the Inconel 690 tube, and offers complete solutions for nuclear and commercial uses. We know a lot about production, quality control, and giving professional help during the whole buying process.

Advanced Manufacturing Capabilities

Our modern building has specialized production lines with state-of-the-art tools designed especially for making nickel alloys. Three companies with eight production lines and more than one hundred precise machines make it possible to produce goods quickly and with high quality. Our quality systems are backed up by ISO 9001 and AS9100D standards, and the fact that we serve more than 70 areas around the world shows how reliable we are.

Our production methods are always getting better because of new technologies. Research and development skills let you make changes to meet the needs of unique apps while still following international standards. Our engineering team offers expert advice to help you choose the best materials and specifications for each job.

Global Service and Support

Support services that cover more than just making include coordinating supplies, writing up paperwork, and giving expert help. For foreign shipping, products are protected with wooden cases or steel boxes, and full records of how the shipment was tracked are sent with every delivery.

Since 2011, when we started dealing internationally, we've built relationships with nuclear power plants all over the world. We are committed to engaging with the global market and keeping up with changing technology needs by actively taking part in industry events.

Conclusion

When it comes to nuclear power uses that need rust protection, mechanical strength, and long-term dependability, Inconel 690 tubes are the best choice. These nickel-chromium metal tubes are safe and reliable to use in the harshest nuclear settings because of their high quality makeup and manufacturing. This tried-and-true material is used by nuclear power plants all over the world for steam generator tubes and important reactor parts whose performance directly affects safety and operating efficiency.

FAQs

1.In nuclear uses, what makes Inconel 690 tubes different from Inconel 600 tubes?

Inconel 690 has more chromium than Inconel 600 (28–31% vs. 14–17% in Inconel 600), which makes it more resistant to main water stress corrosion cracking and better resistant to rust. This better mix of metals protects it from the breaking processes that happen in Inconel 600 in nuclear steam generators.

2.How does Inconel 690 hold up in nuclear plants where temperatures change a lot?

With a melting point between 1343 and 1377°C, the metal is very stable at high temperatures and keeps its tensile qualities at temperatures above 700°C. Its stable lattice doesn't break down when heated and cooled many times, and it keeps its strength and flexibility even when temperatures change, which is common in nuclear operations.

3.How long does it usually take to get Inconel 690 tubes, and how many do I need to order?

Lead times depend on the specs and the number of orders, but for normal measurements, they are usually between 4 and 8 weeks. Common sizes are kept in stock by TSM Technology, but special specs may take more time to make. Minimum order amounts depend on specific measurements and can be discussed based on the needs of the project.

Partner with TSM Technology for Premium Inconel 690 Tube Solutions

TSM Technology is ready to help you with your nuclear project needs by making luxury nickel-chromium alloy tubing to the highest levels of quality. As a seller of Inconel 690 tubes, we can meet all of your needs, including unique specs, fast shipping, and full expert help throughout the whole process of buying from us. We provide the dependability your important applications need with 14 years of experience in the field and quality systems that have been tested and shown to work. For full quotes, technical details, and sample requests, email us at info@tsmnialloy.com.

References

American Society for Testing and Materials. "Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Tubes." ASTM International, West Conshohocken, PA.

Nuclear Energy Institute. "Steam Generator Tube Integrity and Inspection Guidelines for Nuclear Power Plants." Nuclear Energy Institute Technical Report, Washington, DC.

Rebak, R.B. "Alloy 690 - Material for Steam Generator Tubing in Pressurized Water Reactors." Materials Science Forum, Trans Tech Publications.

Electric Power Research Institute. "Materials Reliability Program: Steam Generator Management Program Guidelines." EPRI Technical Report, Palo Alto, California.

International Atomic Energy Agency. "Assessment and Management of Ageing of Major Nuclear Power Plant Components Important to Safety: Steam Generators." IAEA Technical Report Series, Vienna.

Gorman, J.A., Stavropoulos, K.K., and Somerville, J.M. "Inconel Alloy 690 - A New Corrosion Resistant Material for Nuclear Steam Generator Applications." Nuclear Engineering and Design Journal, Elsevier Science Publishers.