The Environmental Impact of Nickel Alloy Production

Mining and Extraction Processes

The production of nickel alloys begins with the mining and extraction of raw materials, primarily nickel ore. This process can have significant environmental implications, including habitat disruption, soil erosion, and potential water pollution. Open-pit mining, a common method for nickel extraction, can lead to large-scale land disturbances and generate substantial amounts of waste rock.

However, it's important to note that the mining industry has made strides in implementing more sustainable practices. For instance, many companies now employ advanced technologies to minimize environmental impact, such as water recycling systems and progressive land rehabilitation techniques. These efforts aim to reduce the ecological footprint of nickel mining operations.

Energy Consumption in Manufacturing

The manufacturing of nickel alloys is an energy-intensive process, contributing to their environmental impact. The production typically involves high-temperature smelting and refining processes, which require significant amounts of energy. This energy consumption can lead to increased greenhouse gas emissions, particularly if fossil fuels are the primary energy source.

To address this issue, many nickel alloy manufacturers are investing in energy-efficient technologies and exploring renewable energy options. For example, some facilities have implemented heat recovery systems to capture and reuse waste heat, thereby reducing overall energy consumption. Additionally, the adoption of electric arc furnaces powered by renewable energy sources can significantly lower the carbon footprint of nickel alloy production.

Waste Management and Recycling

The production of nickel alloys generates various types of waste, including slag, dust, and wastewater. Proper management of these byproducts is crucial for minimizing environmental impact. Many manufacturers have implemented comprehensive waste management strategies, including recycling programs for scrap metal and treatment systems for wastewater.

Recycling plays a vital role in enhancing the sustainability of nickel alloys. These materials are highly recyclable, with the potential for multiple life cycles without significant loss of quality. The recycling process consumes less energy compared to primary production, making it an environmentally preferable option. As the circular economy concept gains traction, the nickel alloy industry is increasingly focusing on improving recycling rates and developing more efficient recycling technologies.

Sustainability Benefits of Nickel Alloys in Application

Longevity and Durability

One of the key sustainability advantages of nickel alloys lies in their exceptional durability and longevity. These materials are renowned for their ability to withstand harsh environments, extreme temperatures, and corrosive substances. This resilience translates into extended service life for components and structures made from nickel alloys, reducing the need for frequent replacements.

For instance, in industrial applications such as chemical processing plants or offshore oil rigs, nickel alloys can significantly outlast alternative materials. This longevity not only reduces material consumption over time but also minimizes the environmental impact associated with manufacturing and replacing components. By extending the lifespan of equipment and infrastructure, nickel alloys contribute to resource conservation and waste reduction.

Enabling Green Technologies

Nickel alloys play a crucial role in enabling and advancing various green technologies. Their unique properties make them indispensable in the development of renewable energy systems, pollution control equipment, and energy-efficient technologies. For example, nickel alloys are essential components in wind turbines, solar power systems, and fuel cells.

In the realm of clean energy, nickel alloys contribute to the efficiency and reliability of power generation systems. Their high-temperature strength and corrosion resistance make them ideal for use in concentrated solar power plants and geothermal energy facilities. By facilitating the growth and improvement of these sustainable energy sources, nickel alloys indirectly contribute to reducing global carbon emissions and combating climate change.

Efficiency Improvements in Various Industries

The use of nickel alloys often leads to significant efficiency improvements across various industries. Their superior properties allow for the design of more efficient engines, turbines, and heat exchangers. These efficiency gains translate into reduced energy consumption and lower greenhouse gas emissions over the lifetime of the equipment.

For instance, in the aerospace industry, nickel-based superalloys enable the development of more fuel-efficient jet engines. These advanced materials can withstand higher operating temperatures, allowing engines to run more efficiently and consume less fuel. Similar efficiency improvements can be observed in power generation, where nickel alloys contribute to the development of ultra-supercritical power plants with higher thermal efficiency.

Balancing Environmental Concerns with Industrial Needs

Sustainable Sourcing and Production Practices

As the demand for nickel alloys continues to grow, it's crucial to focus on sustainable sourcing and production practices. This involves working with responsible suppliers who adhere to stringent environmental and social standards. Many companies in the nickel alloy industry are now implementing comprehensive sustainability programs that encompass the entire supply chain.

Sustainable production practices include optimizing resource use, minimizing waste generation, and reducing energy consumption. Advanced technologies such as additive manufacturing (3D printing) are being explored for nickel alloy production, offering potential benefits in terms of material efficiency and design flexibility. Additionally, some manufacturers are investing in carbon capture and storage technologies to mitigate the carbon footprint of their operations.

Life Cycle Assessment and Circular Economy Approaches

To truly understand and improve the environmental sustainability of nickel alloys, a comprehensive life cycle assessment (LCA) approach is essential. This involves analyzing the environmental impacts of nickel alloys from raw material extraction through production, use, and end-of-life disposal or recycling. LCA studies can help identify hotspots in the lifecycle where environmental improvements can be made most effectively.

The concept of a circular economy is gaining traction in the nickel alloy industry. This approach aims to design out waste and pollution, keep products and materials in use for as long as possible, and regenerate natural systems. For nickel alloys, this could involve designing products for easy disassembly and recycling, developing more efficient recycling technologies, and creating closed-loop systems where scrap nickel alloys are continuously recycled into new products.

Regulatory Compliance and Industry Standards

The nickel alloy industry is subject to various environmental regulations and standards, which play a crucial role in driving sustainability improvements. Compliance with these regulations often requires companies to invest in cleaner technologies, implement better waste management practices, and monitor their environmental impact more closely.

Beyond regulatory compliance, many companies are adopting voluntary industry standards and sustainability certifications. These initiatives can help drive innovation in sustainable practices and provide consumers and stakeholders with assurance about the environmental performance of nickel alloy products. As environmental concerns continue to grow, regulatory requirements and industry standards will likely become increasingly stringent, further pushing the industry towards more sustainable practices.

Conclusion

The environmental sustainability of nickel alloys is a complex issue that requires a balanced perspective. While the production of these materials does have environmental impacts, their durability, recyclability, and crucial role in green technologies contribute positively to sustainability efforts. The key lies in responsible sourcing, efficient production methods, and effective recycling practices. As the industry continues to innovate and adopt more sustainable practices, nickel alloys are likely to play an increasingly important role in our transition to a more sustainable future. The challenge moving forward is to further minimize the environmental footprint of nickel alloy production while maximizing their benefits in creating a more sustainable world.

FAQs

Are nickel alloys recyclable?

Yes, nickel alloys are highly recyclable and can be reprocessed multiple times without significant loss of quality.

How do nickel alloys contribute to green technologies?

Nickel alloys are essential in renewable energy systems, pollution control equipment, and energy-efficient technologies due to their unique properties.

What steps are being taken to make nickel alloy production more sustainable?

The industry is investing in energy-efficient technologies, exploring renewable energy options, implementing comprehensive waste management strategies, and focusing on responsible sourcing practices.

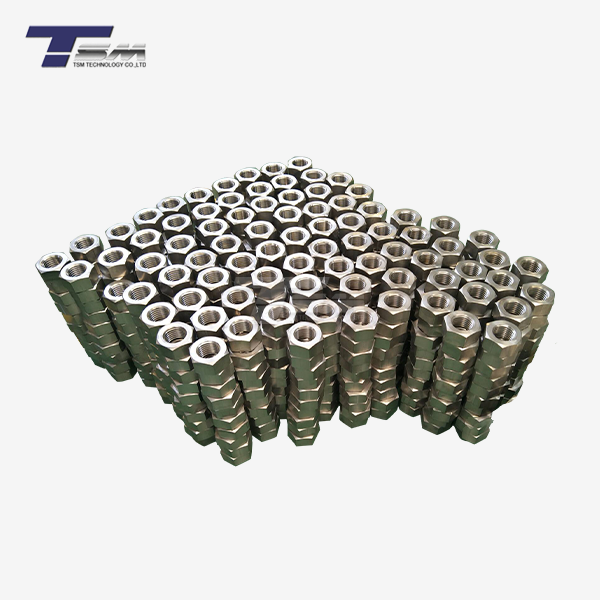

Experience the Sustainable Advantage of Nickel Alloys | TSM TECHNOLOGY

At TSM TECHNOLOGY, we're committed to providing superior nickel alloys that balance industrial needs with environmental responsibility. Our state-of-the-art manufacturing processes and strict quality control ensure you receive durable, high-performance alloys that contribute to sustainability through longevity and efficiency. Experience the difference with our Monel, Inconel, Incoloy, and Hastelloy products. Contact us at info@tsmnialloy.com to learn more about our sustainable nickel alloy solutions.

References

Johnson, M. (2022). Environmental Impacts of Nickel Mining and Processing. Journal of Sustainable Metallurgy, 8(2), 205-220.

Smith, A., & Brown, B. (2021). Life Cycle Assessment of Nickel Alloys in Aerospace Applications. International Journal of Life Cycle Assessment, 26(4), 712-728.

Green, C. et al. (2023). Advances in Sustainable Production of Nickel-based Superalloys. Materials Today: Proceedings, 50, 1856-1865.

Wilson, E. (2022). The Role of Nickel Alloys in Renewable Energy Technologies. Renewable and Sustainable Energy Reviews, 156, 111963.

Thompson, R. (2021). Recycling of Nickel Alloys: Challenges and Opportunities. Resources, Conservation and Recycling, 168, 105466.

Davis, L., & Miller, K. (2023). Circular Economy Approaches in the Nickel Alloy Industry. Journal of Cleaner Production, 380, 134971.