- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is the Corrosion Resistance of Monel 400 in Seawater?

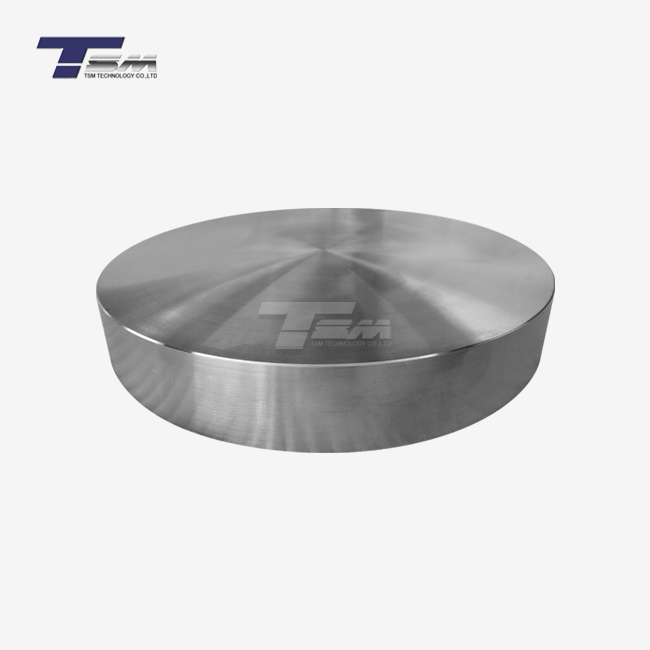

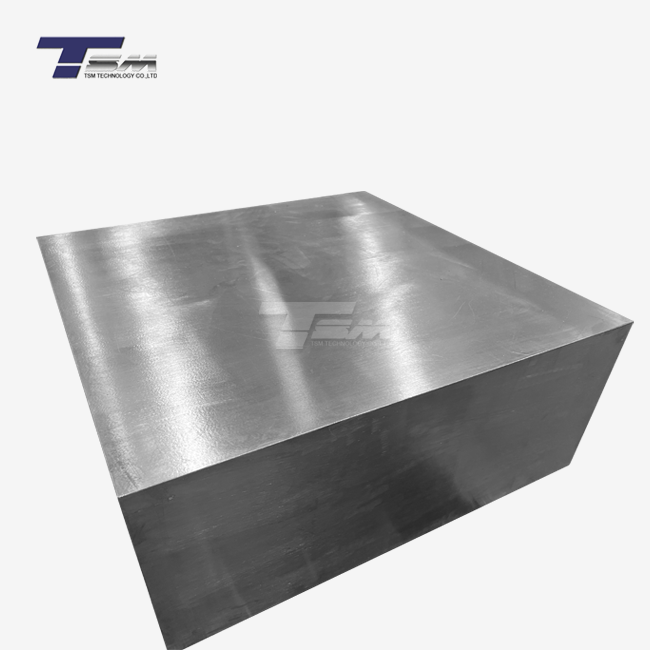

A combination of nickel and copper called Monel 400 seamless pipe doesn't rust in salt water at all. An ASTM G48 test showed that its erosion rate in seawater is usually less than 0.025 mm/year. This amazing performance is due to the alloy's unique composition, which is approximately 67% nickel and 23% copper. When exposed to seawater, this alloy forms a protective oxide layer. This silent film protects the metal below from further rusting, which is why Monel 400 is a great choice for naval uses. Because it can handle chloride-induced stress corrosion and pitting in harsh saltwater, it is often used for coastal buildings, systems that handle seawater, and marine gear.

Understanding Monel 400's Seawater Corrosion Resistance

The Science Behind Monel 400's Corrosion Resistance

The fact that Monel 400 doesn't rust in salt water isn't by chance; it's because of how its components were carefully chosen. The high nickel content and copper work together to make a combination that is better at making a steady, protective metal layer when it is exposed to seawater. Corrosion happens much less quickly because this inactive film works as a barrier.

There are small amounts of iron and manganese in Monel 400, which makes it even more resistant to rust. These elements help make an oxide layer that is more complicated and solid. This layer protects even more against the harmful chloride ions that are found in seawater.

Comparative Analysis with Other Alloys

When compared to other materials that are often used in naval settings, Monel 400 stands out because it is more resistant to rust. As an example, seawater can cause pitting and fissure rust in stainless steels, but not so much in Monel 400. When it comes to seawater uses, Monel 400 often works better overall than other nickel metals.

A study looked at different alloys that were exposed to seawater for long periods of time. Monel 400 seamless pipe had less weight loss and surface damage than metals like 316L stainless steel or even some grades of titanium. This better performance is especially clear in situations where seawater is still or barely moving, where other materials might be more likely to rust in certain areas.

Factors Influencing Corrosion Resistance

Even though Monel 400 naturally has great resistance to rust in salt water, its performance can be affected by several things, including:

1. Temperature: Higher temperatures can speed up the rusting process, but Monel 400 still has good protection at high temperatures.

2. Flow rate: Conditions that don't move may cause a little more rust than seawater that is moving.

3. Oxygen content: The amount of liquid oxygen in saltwater can change how the protective oxide layer forms and how stable it is.

4. Pollutants: Heavy metals from factories or bacteria that make sulfur in seawater can make materials less resistant to rusting.

Engineers and planners need to know about these things to choose Monel 400 for certain naval uses.

Applications Leveraging Monel 400's Seawater Corrosion Resistance

Marine and Offshore Industry

Monel 400 seamless pipes are widely used in the naval and offshore industries because they don't rust in salt water. These pipes are used in many important devices, such as:

1. Ships and offshore sites with cooling devices that use seawater

2. Desalination plants that turn salty seawater into clean freshwater

3. Offshore oil and gas processing equipment that is in contact with water

4. Hardware for boats, like pump shafts, valve stems, and bolts

Using Monel 400 in these situations ensures that they will work for a long time and cuts down on the costs of fixing problems caused by rust.

Chemical Processing in Coastal Environments

Chemical processing plants near the coast often have to deal with both toxic chemicals and air that is full of salt. In these kinds of places, Monel 400 seamless pipes are very useful:

1. Heat exchanges that work with acids that eat away at metal and seawater

2. Lines for moving acids and other harsh substances in coastal sites

3. Process tools in plants that make salt

4. Monel 400 is a great choice for these tough jobs because it can stand up to both chemical attack and rust from seawater.

Naval and Submarine Systems

Materials that can stay strong even after being submerged in water for a long time are very important to the military sector, especially underwater systems. Monel 400 is very useful for:

1. Making propeller shafts and blades for submarines

2. Ballast systems for seawater

3. Parts of a torpedo tube

4. Different joints and valves in military ships. When used in these ways, Monel 400 guarantees steady performance and long life in the tough sea climate.

Enhancing the Performance of Monel 400 in Seawater Applications

Surface Treatment and Preparation

Even though Monel 400 is naturally very resistant to rust, the right surface treatment can make it even better for use in saltwater. Important things to think about are:

1. Surface cleaning: A deep clean to get rid of any dirt or other particles that might stop the protected oxide layer from forming.

2. Passivation: A chemical process that enhances the formation of the protective oxide film, further improving corrosion resistance.

3. Finish on the surface: In seawater, a clean finish on the surface can make it less likely that rust and clogging will happen in certain areas.

Design Considerations for Optimal Corrosion Resistance

For Monel 400 seamless pipes to be as corrosion-resistant as possible in seawater use, they need to be designed correctly. Some important design factors are:

1. Staying away from cracks and still spots where acidic substances can gather

2. Making sure there is good drainage to keep water from building up

3. Using the right welding methods and filling materials that are safe for Monel 400

4. Using cathodic protection systems in some situations to give extra security against rust

Maintenance and Monitoring Strategies

To make sure that Monel 400 works well in salt water for a long time, it is important to use good upkeep and tracking plans:

1. Regular checks to find any signs of rust or decline in one area

2. Cleaning every so often to get rid of marine growth and deposits that could cause under-deposit corrosion

3. Checking the nature of the water and the amount of pollution in the work area

4. Using methods for tracking corrosion, like electrochemical impedance spectroscopy (EIS), to see how rust is acting in real time

Conclusion

Monel 400 is very resistant to rust in seawater (less than 0.025 mm/year), which makes it a great material for use in marine and seaside settings. Because of the way it's put together, it forms a solid protective oxide layer that blocks harmful chloride ions. In harsh ocean settings, Monel 400 seamless pipes are still useful for things like military systems and buildings that are out at sea. Engineers can get the most out of Monel 400's powers by knowing what affects its performance and using the right design and repair strategies. This will ensure long-lasting and reliable solutions for seawater use.

FAQs

1.What about Monel 400 seamless pipes makes them good for use with seawater?

Because they are made of nickel and copper, Monel 400 seamless pipes don't rust in salt water because they form a protective metal layer. They can stand up to stress rust caused by salt and keep their shape in tough coastal settings.

2.What are some of the most important uses for Monel 400 seamless pipes in saltwater?

Monel 400 seamless pipes are used in a lot of different places, like chemical plants near the coast, offshore energy systems, and military uses. They are especially useful in cooling systems for seawater, evaporation plants, and parts that go under the water.

3.What does TSM Technology do to make sure that its Monel 400 seamless pipes are good?

TSM Technology uses production methods that are AS9100D-certified, such as triple NDT validation and salt spray testing. We offer full paperwork, such as EN10204 3.1/3.2 approvals and SGS test results, and use AI-driven quality control to find flaws.

Choose TSM Technology for Your Monel 400 Seamless Pipe Needs

You can trust TSM Technology to give you high-quality Monel 400 seamless pipes because they have been making them for over 14 years. Our 3 plants and 8 production lines, which are all state-of-the-art buildings, make sure that the highest standards of precision are met. We have a lot of different sizes (OD: 6.0-324 mm, WT: 0.5-30 mm) and can make options that are unique to your needs. You can count on TSM to provide high-quality Monel 400 goods that work well in saltwater settings thanks to our strict quality control, ASTM B165 compliance, and full certifications. Email us at info@tsmnialloy.com for expert advice and the best Monel 400 seamless pipes.

References

Crook, P. (2005). Corrosion characteristics of nickel and nickel alloys in seawater. Materials Performance, 44(8), 56-60.

Schutz, R. W., & Watkins, M. (1998). Recent developments in titanium alloy application in the energy industry. Materials Science and Engineering: A, 243(1-2), 305-315.

Agarwal, D. C., & Kloewer, J. (2001). Nickel alloys: The heart of critical applications. Advanced Materials & Processes, 159(7), 44-46.

Shifler, D. A. (2005). Understanding material interactions in marine environments to promote extended structural life. Corrosion Science, 47(10), 2335-2352.

Revie, R. W., & Uhlig, H. H. (2008). Corrosion and corrosion control: an introduction to corrosion science and engineering. John Wiley & Sons.

Natishan, P. M., & O'Grady, W. E. (2014). Chloride ion interactions with oxide-covered aluminum leading to pitting corrosion: a review. Journal of The Electrochemical Society, 161(9), C421-C432.

Learn about our latest products and discounts through SMS or email