- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Testing Methods Are Required for Inconel 686 Tube Quality?

A wide range of testing methods is needed to make sure the standard of Inconel 686 tubes. Some of these are eye inspection, checking the size and shape, chemical makeup analysis, mechanical property tests, non-destructive tests like ultrasound and eddy current testing, and rust resistance tests. Each way is very important for making sure the tube is solid, works well, and meets industry standards. For very important tasks, more complex methods like microscope analysis and stress corrosion cracking tests may also be used. All of these strict testing methods make sure that Inconel 686 tubes can handle the tough conditions found in industrial settings.

Essential Quality Control Tests for Inconel 686 Tubing

Visual and Dimensional Inspection

Visual and physical checks are the first step in making sure that Inconel 686 tubes are of good quality. Skilled workers carefully look over the outside of each tube for flaws like scratches, holes, or changes in color. By going through this process, the tubes are made to look good and be strong enough for their intended use.

Dimensional checks are just as important. Calibrated tools are used to get accurate readings of the length, wall thickness (WT), and outer diameter (OD). Typical requirements for Inconel 686 tubes are:

- OD: 6 to 114 mm

- WT: 0.5 to 15 mm

- Length: up to 15,000 mm

To make sure they fit and work right in a variety of industrial systems, these values must be very close to the true value.

Chemical Composition Analysis

The unique qualities of Inconel 686 tubes come from the exact chemicals that make them up. Manufacturers use high-tech spectrometric methods like X-ray fluorescence (XRF) or optical emission spectroscopy (OES) to check this. These ways look at the alloy's elements to make sure it meets the requirements of UNS N06686.

Some important parts and how they usually come together are:

- Nickel: at least 59.0%

- 19.0 to 23% chromium

- 15.0% to 17.0% molybdenum

- 3.0 to 4.4% tungsten

For the tube to keep its rust protection and tensile qualities, it needs to have the right makeup.

Mechanical Property Testing

For Inconel 686 tubes to work effectively in harsh conditions, they need to have certain mechanical properties. Some common engineering tests are:

- Tensile testing: Checks for strength and flexibility

- Hardness testing: Uses the Rockwell or Brinell scales to measure how hard an object is.

- Flattening and flaring tests: Assess formability and ductility

These tests make sure that the tubes meet or go beyond industry standards like ASTM B622 and ASME SB622, which say that the tubes must have a minimum tensile strength of 690 MPa, a minimum yield strength of 310 MPa, and a minimum extension of 40%.

Advanced Non-Destructive Examination Techniques

Ultrasonic Testing (UT)

Ultrasonic testing is an important way to look at Inconel 686 tubes without damaging them. High-frequency sound waves are used in this method to find problems inside the tube, like spots, gaps, or cracks that could weaken it. UT is especially good at finding flaws that might not be obvious at first glance.

Parts of the process are:

- Putting a binding medium on the pipe's surface

- Ultrasonic sounds are sent through the object.

- Looking at the mirrored waves to find strange things

- Using the data to figure out if and what kind of flaws are present

UT is necessary to make sure that Inconel 686 tubes are structurally sound, especially in situations where failure could have very bad results.

Eddy Current Testing (ECT)

Another important non-destructive way to check Inconel 686 tubes is with eddy current testing. This method works especially well for finding flaws on the surface or very close to the surface, as well as changes in the material's qualities. ECT works by creating electric fields inside the tube and studying the eddy currents that come up as a result.

Some of the best things about ECT are:

- The check goes quickly

- Very sensitive to small flaws

- Being able to find flaws both inside and outside

- There's no need for pairing media.

It is common to use ECT along with other testing methods to get a full picture of the quality of a tube.

Radiographic Testing (RT)

Radiographic testing can be used to check Inconel 686 tubes for use in serious situations. With this method, X-rays or gamma rays are used to make pictures of the inside of the tube, which show problems that other methods might miss.

- One thing that RT is great for is finding internal gaps or additions.

- Checking the strength of the weld in welded tubes

- Looking at changes in wall thickness

Even though it takes longer and costs more than other ways, RT gives the best picture of the tube's state from the inside, guaranteeing the highest level of quality.

Specialized Corrosion and Performance Testing

Corrosion Resistance Evaluation

The fact that Inconel 686 tubes are very resistant to rust is a key feature that needs to be thoroughly checked. Specialized rust tests make the hard conditions that these tubes will be used in feel like real life. Some common ways to test for rust are:

- Immersion tests in different acidic and basic waters

- To check pitting resistance, cyclic polarization tests are used.

- Tests for crevice rusting in places with chloride

- Under tension force, stress corrosion cracking (SCC) tests are done.

These tests make sure that Inconel 686 tubes stay strong even when they are used in harsh chemical processes, at sea, or in the environment.

High-Temperature Performance Testing

Because Inconel 686 tubes are often used in places with high temperatures, they need to be tested in special ways to make sure they work well in those places. Some examples of high-temperature tests are

- Testing for creep to see how much something deforms over time when it is constantly stressed

- To test resistance to thermal stress, thermal cycling is used.

- Tests of oxidation resistance at high temperatures

With these tests, we know that the tubes will stay strong and not rust at temperatures up to 1000°C, which is what many commercial uses need.

Specialized Industry-Specific Tests

Depending on what they are going to be used for, Inconel 686 tubes may have to go through more specific tests. As an example:

- Testing for fatigue in situations with changing loads

- Resistance tests to hydrogen embrittlement for industrial use

- Checks for cleanliness and germs on pharmaceutical grade tubes

These special tests make sure that the tubes meet the specific needs of certain businesses and uses, which gives buyers trust in the product's performance.

Conclusion

The thorough testing methods needed to make sure the quality of Inconel 686 tubes show how important this high-performance material is. Each step, from simple eye checks to advanced non-destructive tests and specific rust tests, makes sure that the tubes meet the high standards needed by the industry. When companies like TSM Technology use these strict testing methods, they can guarantee that their Inconel 686 tubes will work perfectly in the toughest conditions. This dedication to quality not only meets the needs of customers but also helps make sure that important industry processes around the world are safe and reliable.

FAQs

What are the most important ways to test Inconel 686 tubes?

Visual inspection, measurement checks, chemical makeup analysis, mechanical property tests, non-destructive examinations (ultrasonic and eddy current testing), and rust resistance evaluations are some of the most important testing methods.

Why is it important to look at the chemistry make-up of Inconel 686 tubes?

Chemical composition analysis makes sure that the right amount of nickel, chromium, molybdenum, and tungsten are in the tube. This is important for keeping the tube's mechanical and corrosion-resistant properties.

How does TSM Technology make sure that its Inconel 686 tubes are good?

To make sure that the Inconel 686 tubes they sell are of the best quality, TSM Technology uses a full quality control system that includes cutting edge testing methods, cutting edge tools, and strict obedience to international standards.

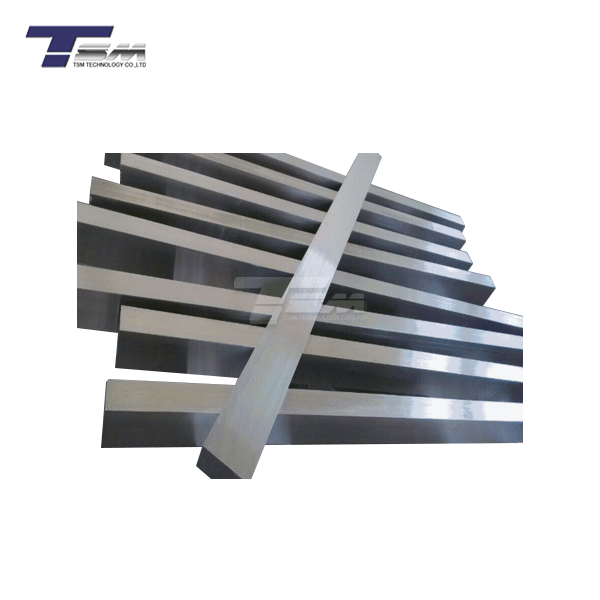

TSM Technology: Your Trusted Partner for Premium Inconel 686 Tubes

We are proud at TSM Technology to offer Inconel 686 tubes that are of the highest quality and go above and beyond what the industry requires. We can give 300 tons of goods every month thanks to our modern facilities, which include 3 plants, 8 production lines, and more than 100 tools. Your exact needs are carefully taken into account when we carefully make our tubes, which have ODs from 6.0 mm to 114 mm and WTs from 0.5 mm to 15 mm and lengths up to 15000 mm. You can count on our more than 14 years of experience and thorough testing methods to give you Inconel 686 tubes that work perfectly in the toughest situations. Contact us at info@tsmnialloy.com for the best options for corrosion-resistant tubing.

References

ASTM International. (2021). "ASTM B622 - Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube"

American Society of Mechanical Engineers. (2019). "ASME Boiler and Pressure Vessel Code, Section II: Materials"

Special Metals Corporation. (2020). "INCONEL® alloy 686 Technical Data Sheet"

ASM International. (2018). "Handbook of Materials for Medical Devices: Corrosion-Resistant Alloys"

Nace International. (2021). "Corrosion Testing Methods for High-Performance Alloys in Aggressive Environments"

The American Society for Nondestructive Testing. (2019). "Nondestructive Testing Handbook: Ultrasonic Testing"

Learn about our latest products and discounts through SMS or email