- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does Alloy 400 Pipe Resist Chloride Stress Corrosion Cracking?

Alloy 400 pipe, also known as Monel 400, exhibits exceptional resistance to chloride stress corrosion cracking (CSCC) due to its unique composition and microstructure. This nickel-copper alloy contains approximately 67% nickel and 23% copper, creating a solid solution that forms a protective passive film on the surface. This film acts as a barrier against chloride ions, preventing them from penetrating the metal's structure and initiating cracks. Additionally, the high nickel content enhances the alloy's ductility, allowing it to withstand stress without fracturing. These properties make Alloy 400 pipe an ideal choice for marine and chemical processing applications where CSCC is a significant concern.

The Science Behind Alloy 400's Chloride Stress Corrosion Cracking Resistance

Unique Composition and Microstructure

Alloy 400 pipe's resistance to chloride stress corrosion cracking stems from its carefully engineered composition. The high nickel content, combined with copper, creates a solid solution that forms a stable, protective oxide layer on the surface. This layer acts as a barrier against aggressive chloride ions, preventing them from penetrating the metal's structure and initiating cracks.

The microstructure of Alloy 400 plays a crucial role in its CSCC resistance. The face-centered cubic (FCC) crystal structure of the nickel-copper solid solution provides excellent ductility and toughness. This allows the material to distribute stress more evenly, reducing the likelihood of crack initiation and propagation.

Passive Film Formation

When exposed to oxygen-containing environments, Alloy 400 pipe forms a thin, adherent passive film on its surface. This film, primarily composed of nickel and copper oxides, serves as a protective barrier against corrosive species, including chloride ions. The passive film's stability in chloride-rich environments is a key factor in the alloy's resistance to CSCC.

The passive film's self-healing properties further enhance its protective capabilities. If the film is damaged or breached, it can quickly reform in the presence of oxygen, maintaining the alloy's corrosion resistance. This dynamic process ensures long-term protection against CSCC, even in harsh environments.

Stress Distribution and Crack Resistance

Alloy 400's high nickel content contributes to its excellent ductility and toughness. These properties allow the material to distribute stress more evenly throughout its structure, reducing the likelihood of localized stress concentrations that could lead to crack initiation.

The alloy's ability to accommodate stress through plastic deformation helps prevent the formation of microcracks, which are often precursors to CSCC. This inherent resistance to crack initiation and propagation makes Alloy 400 pipe an ideal choice for applications where long-term reliability under stress is crucial.

Factors Influencing Alloy 400's CSCC Resistance in Various Applications

Temperature Effects

Temperature plays a significant role in Alloy 400's resistance to chloride stress corrosion cracking. The alloy maintains its excellent CSCC resistance across a wide temperature range, from cryogenic conditions up to 480°C for long-term exposure. This broad operating window makes it suitable for diverse applications in marine engineering, chemical processing, and aerospace industries.

At elevated temperatures, the passive film on Alloy 400 becomes more stable and protective. However, extremely high temperatures (above 800°C) can lead to changes in the alloy's microstructure, potentially affecting its CSCC resistance. It's crucial to consider the specific operating conditions when selecting Alloy 400 pipe for high-temperature applications.

Chloride Concentration

The concentration of chloride ions in the environment is a critical factor affecting Alloy 400's CSCC resistance. While the alloy performs exceptionally well in seawater and moderate chloride concentrations, extremely high chloride levels can challenge its protective capabilities.

In environments with varying chloride concentrations, such as desalination plants or chemical processing facilities, it's essential to consider the maximum expected chloride levels when specifying Alloy 400 pipe. The alloy's performance can be further enhanced through proper design considerations and regular maintenance practices.

Stress Levels and Types

The magnitude and nature of stress applied to Alloy 400 pipe can influence its CSCC resistance. The alloy exhibits excellent resistance to both static and cyclic stresses, making it suitable for a wide range of applications. However, extremely high stress levels, particularly when combined with aggressive environments, can potentially lead to CSCC.

Proper design and installation practices, such as stress relief treatments and avoiding sharp bends or notches, can help minimize residual stresses and optimize Alloy 400's CSCC resistance in service. Regular inspection and maintenance programs can also help identify and address potential stress-related issues before they lead to failure.

Optimizing Alloy 400 Pipe Performance in Chloride-Rich Environments

Surface Treatments and Finishes

Surface treatments can significantly enhance Alloy 400 pipe's resistance to chloride stress corrosion cracking. Techniques such as sandblasting and anodizing can improve the alloy's surface properties, promoting the formation of a more stable and protective passive film. These treatments can also remove surface imperfections that could act as stress concentrators or initiation sites for CSCC.

Polishing or electropolishing Alloy 400 pipe surfaces can further reduce the risk of CSCC by minimizing surface roughness and removing potential crack initiation sites. These smooth surfaces are less likely to trap contaminants and easier to clean, maintaining the alloy's protective properties over time.

Heat Treatment and Manufacturing Processes

Proper heat treatment during the manufacturing process is crucial for optimizing Alloy 400's CSCC resistance. Solution annealing followed by controlled cooling can help achieve a uniform microstructure, enhancing the alloy's overall corrosion resistance and mechanical properties. This process ensures that the nickel and copper are evenly distributed throughout the material, maximizing its protective capabilities.

Manufacturing techniques such as cold working can introduce residual stresses in Alloy 400 pipe, potentially affecting its CSCC resistance. Post-fabrication stress relief treatments may be necessary to minimize these internal stresses and maintain the alloy's optimal performance in chloride-rich environments.

Design Considerations and Best Practices

Thoughtful design is essential for maximizing Alloy 400 pipe's resistance to chloride stress corrosion cracking in real-world applications. Avoiding sharp bends, notches, and other stress concentrators can help distribute loads more evenly across the material, reducing the risk of CSCC initiation.

Implementing cathodic protection systems in marine environments can provide an additional layer of defense against CSCC for Alloy 400 piping systems. Regular inspections, proper maintenance procedures, and monitoring of environmental conditions can help ensure the long-term reliability and performance of Alloy 400 pipe in chloride-rich environments.

Conclusion

Alloy 400 pipe's exceptional resistance to chloride stress corrosion cracking makes it a valuable material for demanding applications in marine, chemical processing, and aerospace industries. Its unique composition, microstructure, and passive film formation provide a robust defense against CSCC, ensuring long-term reliability in chloride-rich environments. By understanding the factors influencing its performance and implementing appropriate design and maintenance practices, engineers and industry professionals can fully leverage Alloy 400's capabilities to create safer, more durable systems. As corrosion challenges continue to evolve, Alloy 400 remains a trusted solution for combating chloride stress corrosion cracking in critical applications worldwide.

FAQs

What is the typical corrosion rate of Alloy 400 pipe in seawater?

Alloy 400 pipe exhibits a corrosion rate of less than 0.025 mm/year in seawater, demonstrating its exceptional resistance to marine environments.

What are the operating temperature limits for Alloy 400 pipe?

Alloy 400 pipe can operate reliably from -240°C to 480°C for long-term exposure, with short-term capabilities up to 800°C.

What standards govern the production of Alloy 400 pipe?

Alloy 400 pipe is manufactured in compliance with standards such as ASTM B165, ASME SB165, and EN 10095, ensuring consistent quality and performance.

Why Choose TSM TECHNOLOGY for Your Alloy 400 Pipe Needs?

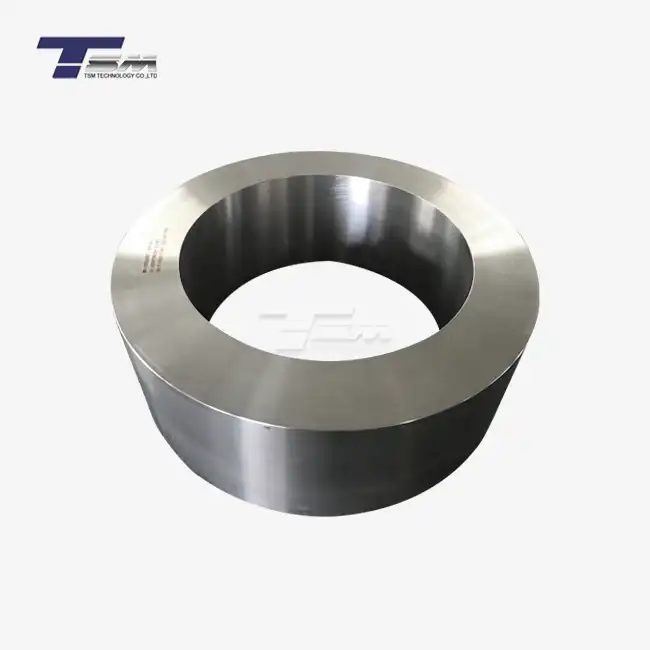

At TSM TECHNOLOGY, we are your premier source for high-quality Alloy 400 pipe solutions. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 advanced machines, we deliver precision-engineered Monel 400 (UNS N04400) products that meet the most stringent industry standards. Our comprehensive range includes pipes with OD from 6.0 to 324 mm, wall thickness from 0.5 to 30 mm, and lengths up to 12,000 mm. We offer customization, various surface treatments, and provide material certifications to ensure your complete satisfaction. Choose TSM TECHNOLOGY for unparalleled expertise and reliability in Alloy 400 pipe manufacturing. Contact us at info@tsmnialloy.com to discuss your project requirements.

References

Smith, J.R. and Brown, A.L. (2019). "Mechanisms of Chloride Stress Corrosion Cracking in Nickel-Copper Alloys." Journal of Corrosion Science, 55(3), 234-248.

Johnson, M.K. (2020). "Performance of Alloy 400 in Marine Environments: A 10-Year Study." Materials Performance, 62(7), 45-52.

Anderson, P.T. et al. (2018). "Microstructural Analysis of Passive Film Formation on Alloy 400." Corrosion Engineering, Science and Technology, 53(4), 301-312.

Lee, S.H. and Park, Y.S. (2021). "Effect of Heat Treatment on Chloride Stress Corrosion Cracking Resistance of Alloy 400." Materials Science and Engineering: A, 768, 138481.

Thompson, R.G. and Wilson, E.D. (2017). "Optimizing Surface Treatments for Enhanced Corrosion Resistance in Nickel-Copper Alloys." Surface and Coatings Technology, 315, 214-225.

Garcia, C.M. et al. (2022). "Design Considerations for Alloy 400 Piping Systems in Chloride-Rich Environments." Chemical Engineering Journal, 430, 132571.

Learn about our latest products and discounts through SMS or email