- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

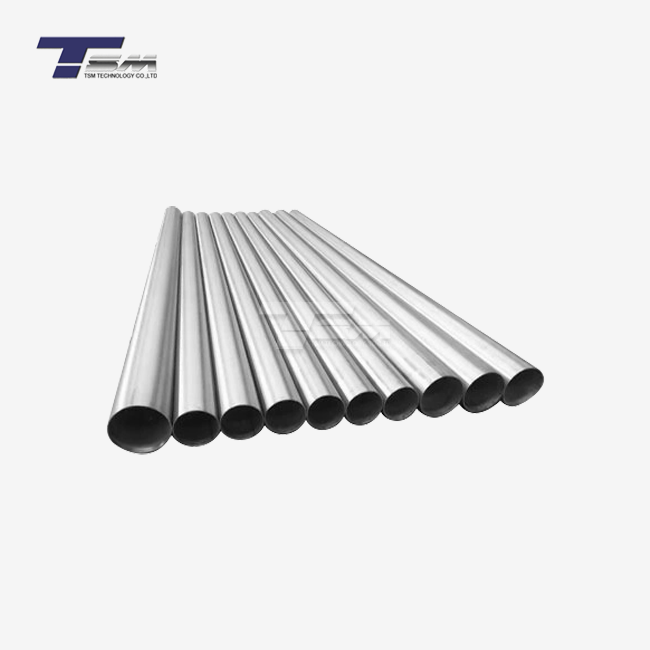

What Pressure Ratings Apply to Monel 400 Seamless Pipe?

Monel 400 seamless pipes are well known for their ability to handle a lot of pressure. For normal uses, they're usually rated up to 3,000 psi (20.7 MPa). But the exact pressure number varies on the temperature, width, and diameter of the pipe, among other things. For example, a Schedule 80 2-inch Monel 400 pipe can handle up to 4,960 psi of pressure at room temperature. Monel 400 lines that are specially designed have been able to handle more than 10,000 psi of pressure in very harsh conditions. For exact pressure values in your application, it is very important to look at the manufacturer's specs and follow the ASME B31.3 rules.

Understanding Pressure Ratings for Monel 400 Seamless Pipes

Factors Influencing Pressure Ratings

The pressure levels of Monel 400 seamless pipes depend on a number of important factors. How thick the wall is very important because bigger walls can usually handle more pressure. The pipe's diameter also affects how much pressure it can handle; smaller sizes usually mean the pipe can handle more pressure. Also, the pressure number depends a lot on the temperature at which it is working. Usually, higher temperatures lower the maximum allowed pressure.

Standard Pressure Classes

The usual pressure classes for Monel 400 seamless pipe include Class 150, 300, 600, 900, 1500, and 2500. These groups are based on the ASME B16.5 standard and show you how much pressure different temperatures can handle. For instance, a Monel 400 pipe of Class 600 can handle 1,440 psi at room temperature, but a Class 2500 pipe can handle up to 6,000 psi in the same circumstances.

Temperature Considerations

The temperature is very important in figuring out the pressure number of Monel 400 seamless pipes. As it gets hotter, the material gets weaker, which lowers the pressure values. For example, a pipe that can handle 3000 psi at room temperature might only be able to handle 2500 psi at 200°C (392°F). When choosing Monel 400 lines for your project, you need to pay attention to both the highest temperature and pressure they can work at.

Calculating Pressure Ratings for Monel 400 Seamless Pipes

Barlow's Formula

The maximum allowed working pressure (MAWP) for Monel 400 seamless pipe is frequently determined by engineers using Barlow's method. P = (2 * S * t) / D is the formula.

Where:

- P = Maximum allowable working pressure

- S = Maximum allowable stress (derived from ASME B31.3)

- t = Minimum wall thickness

- D = Outside diameter of the pipe

This figure shows the possible maximum pressure. It is then changed using safety factors and the needs of the particular application.

ASME B31.3 Guidelines

The ASME B31.3 Process Piping Code gives complete advice on how to find the pressure values of Monel 400 seamless pipes used in a range of industries. This code looks at things like safety, material qualities, and how the system will be used. Following these steps makes sure that the chosen pipes meet the rules and keep things safe while they are being used.

Finite Element Analysis (FEA)

Engineers may use Finite Element Analysis to get a really good idea of how much pressure Monel 400 seamless pipes can handle. They do this for complicated or very important projects. Some things that may not be fully taken into account by normal formulas are complex shapes, areas of high stress, and changing conditions of dynamic loading. FEA models can take all of these things into account. This more in-depth study helps make pipe designs better and makes sure they can be used in tough conditions.

Applications and Considerations for High-Pressure Monel 400 Seamless Pipes

Offshore Oil and Gas Industry

Monel 400 seamless pipes are often used in offshore oil and gas uses where they are under very high pressure and in conditions that eat away at the metal. These pipes are used in underwater systems, where the pressure can be over 5,000 psi. Monel 400 is a great choice for these tough uses because it can handle both high pressure and rust. It's important to think about things like how deep the ocean is, how much the temperature changes, and whether the pipes might be exposed to hydrogen sulfide when they are used in these kinds of settings.

Chemical Processing Plants

Chemical processing plants often use Monel 400 seamless pipes in systems with high pressure that carry fluids that can damage pipes. In these places, pipes may need to handle pressures up to 3000 psi while also fighting damage from acids and alkaline solutions. In these kinds of uses, the pressure grade of Monel 400 lines has to take into account the fluid's pressure as well as the extra stress that the chemical surroundings can cause.

Aerospace and Defense Applications

Monel 400 seamless pipes are used in hydraulic systems and fuel lines that work under high pressure in the aircraft and military industries. These systems may need pipes that can handle 6000 psi or more. When engineers choose Monel 400 pipes for these important uses, they have to think about pressure rates as well as temperature cycling, shaking tolerance, and wear resistance.

Conclusion

To make sure that the difficult industrial tasks that use Monel 400 seamless pipes are done safely and correctly, you need to know their pressure values. These pipes can handle a lot of pressure, but when figuring out the right pressure grade, you should think about the pipe's size, the temperature where it will be used, and the standards that apply to your industry. Engineers can be sure that their high-pressure systems will work well and dependably over time by choosing the right Monel 400 seamless pipes. They do this by thinking about each part carefully and talking to knowledgeable pipe makers.

FAQs

1.What is the highest pressure that can be used with Monel 400 seamless pipes?

For normal uses, the highest pressure number is 3,000 psi, but in very harsh conditions, specially designed pipes can handle more than 10,000 psi.

2.How does the temperature impact the pressure number of pipes made of Monel 400?

Most of the time, higher temperatures lower the highest pressure that is okay. For instance, a pipe that can handle 3000 psi at room temperature may only be able to handle 2500 psi at 200°C.

3.What companies frequently use high-pressure Monel 400 seamless pipe?

Monel 400 pipes are often used in high-pressure situations because they are strong and resistant to rust. They are used in the aircraft, chemical processing, and oil and gas industries.

Experience the TSM Technology Advantage

With 14 years of experience making high-quality Monel 400 seamless pipes, TSM Technology is able to do great work. With three plants, eight production lines, and over one hundred tools, our cutting-edge facilities guarantee that every pipe we make is accurate and dependable. To meet your exact needs, we offer customization, extensive testing, and legal paperwork for use around the world. Feel the change with TSM Technology, your reliable source for better metal options. Email info@tsmnialloy.com if you want more information or to get a price.

References

ASME B31.3-2018: Process Piping. American Society of Mechanical Engineers, 2018.

Monel Alloy 400 - Special Metals Corporation Technical Bulletin, 2018.

Fontana, M.G. Corrosion Engineering. McGraw-Hill Education, 2018.

Nayyar, M.L. Piping Handbook. McGraw-Hill Education, 2000.

ASM Handbook, Volume 13B: Corrosion: Materials. ASM International, 2005.

Bhadeshia, H.K.D.H. and Honeycombe, R. Steels: Microstructure and Properties. Butterworth-Heinemann, 2017.

Learn about our latest products and discounts through SMS or email