Three different surface treatments for Inconel 686 tube are sandblasting, electropolishing (EP), and chemical polishing (CP). All of these are meant to improve the tube's performance and protection to corrosion. These special treatments bring out the best in the superalloy's natural properties while also passing strict industrial standards for use in marine, chemical processing, and aerospace. Knowing the different finishing options helps engineers and procurement teams choose the best surface treatment for their unique work environments and performance needs.

Overview of Surface Finishes for Inconel 686 Tube

Surface cleaning is an important part of the manufacturing process that has a big effect on how well nickel-based superalloy tubing works. The UNS N06686 alloy is known for being very resistant to corrosion in harsh chemical conditions. Choosing the right surface treatment can make it even better. To meet strict industrial standards, these specialized methods change the surface topography, make it more resistant to chemicals, and improve its mechanical properties.

When working in harsh conditions, the link between the quality of the surface finish and the overall performance of the tube becomes even clearer. Facilities that handle chemicals, marine platforms at sea, and aerospace uses all need tubes that can keep their shape and resist corrosion, oxidation, and mechanical stress. The right choice of surface treatment has a direct effect on how reliable the equipment is, how often it needs to be maintained, and how safe it is to use.

Modern finishing methods have changed over time to deal with the unique problems that come up in superalloy uses. Depending on the needs of the product, advanced electrochemical processes, precise mechanical treatments, and specialized chemical treatments all have their own benefits. Knowing about these choices helps you make a smart choice that balances performance goals with cost concerns and output schedules.

Common Types of Surface Finishes Available for Inconel 686 Tube

This superalloy's nickel, chromium, molybdenum, and tungsten make it very responsive to different finishing methods, each of which is meant to improve specific performance traits. Here are the main surface treatments that can be used to improve tube performance:

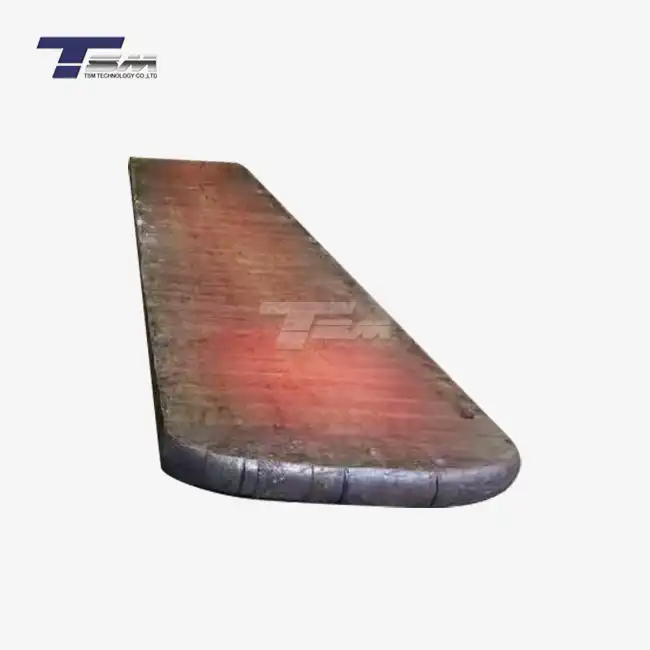

Sandblasting Treatment: This mechanical finishing method gets rid of surface imperfections and makes the surface smooth, making it perfect for welding. The controlled gritty action gets rid of mill scale, oxidation, and surface contamination that could weaken the strength of the joint or make it more likely to rust. Sandblasting works especially well for tasks that need a perfectly smooth surface for important building processes.

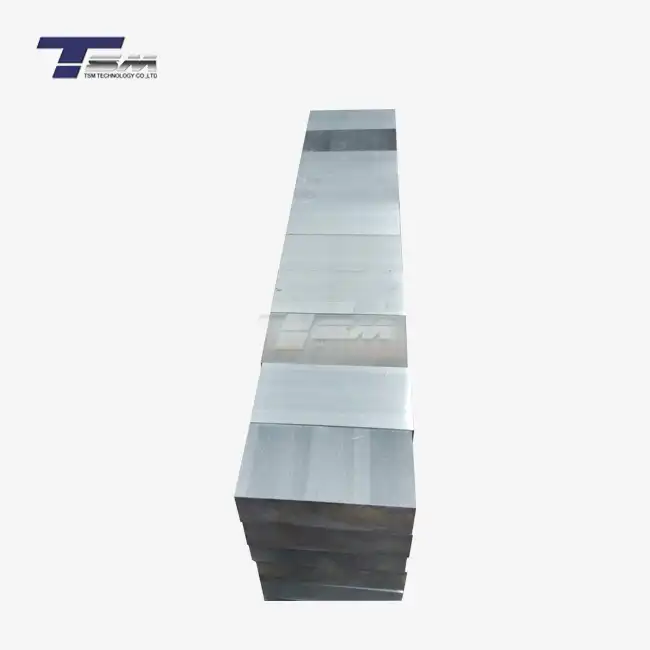

Electropolishing, or EP, is an electrochemical process that makes the surface of Inconel 686 tube very smooth and clean by controlling the breakdown of surface material. Electropolishing improves corrosion protection beyond what the alloy already has by getting rid of surface flaws that are common places for corrosion to start. In pharmaceutical and food processing, the method also makes things easier to clean and lessens the buildup of particles.

Chemical polishing (CP): This method uses special chemical solutions to make the surface smoother in a controlled way, without having to be as precise with the dimensions as electropolishing. Chemical cleaning is an inexpensive way to improve the surface of something that only needs a little help. The process keeps the dimensions stable while making the surface finish better and making the material more resistant to rust.

These finishing choices give you the freedom to meet a wide range of application needs while still keeping the excellent qualities that make Inconel 686 perfect for harsh industrial settings.

How Surface Finishes Influence the Performance of Inconel 686 Tubes

The choice of surface finish has a huge effect on how well a tube works in a lot of different operating situations. When working with harsh chemicals, where normal materials break down quickly, the better corrosion protection that comes from proper finishing becomes even more important. Compared to standard mill finishes, electropolished surfaces are better at resisting pitting corrosion, crevice corrosion, and stress corrosion cracking.

When the surface is properly treated, temperature performance factors also get a lot better. Smooth, clean surfaces don't let oxidation start or spread at high temperatures, so the structure stays strong even after many rounds of high temperatures. This is very important in power generation uses where tubes work all the time at temperatures close to 1000°C.

Finished tubes have better fatigue resistance and less stress concentration when it comes to their mechanical qualities. When there is cyclic stress, surface irregularities are often where cracks start. When you finish something the right way, you get rid of these possible weak spots. This makes it last longer in demanding situations like aerospace power systems and offshore platform components.

When surface roughness is reduced, fluid dynamics improve, especially in heat exchanger and pipe uses. Smoother internal surfaces lower pressure drops, make heat movement more efficient, and lower the chance of fouling. These improvements in performance immediately lead to lower operating costs and better system efficiency over the lifecycle of the equipment.

Selecting the Right Surface Finish for Your Application

Application-specific requirements drive surface finish selection decisions that balance performance objectives with economic considerations. Electropolished surfaces are often needed in chemical handling areas to make them more resistant to corrosion and make cleaning easier. Investing in high-quality finishing pays off because the equipment lasts longer and needs less upkeep in these tough situations.

For aerospace uses, sandblasted finishes are often required for parts that need to be welded or coated later. The even surface texture makes the bond stronger while keeping the exact measurements that are needed for putting together airplane parts. Quality standards like AS9100D require all finishing processes to be documented so that results are the same from one production run to the next.

Chemical polishing treatments make things such as Inconel 686 tube more resistant to corrosion in seawater and are cost-effective for big projects. These treatments are useful in marine and offshore settings. Finding the right balance between better performance and cost-effectiveness is especially important in marine building, where the costs of materials are big project investments.

Lead time affects the choice of finish, especially when a job needs to be done quickly. Electropolishing takes longer to do because the tools and process control are more complicated. Standard sandblasting and chemical polishing usually take less time. Knowing how these time relationships work helps project managers make the most of delivery plans while still meeting quality standards.

How We Support You with Customized Surface Finishing Solutions for Inconel 686 Tubes?

TSM Technology can make anything, and their manufacturing services include all the main surface finishing choices for superalloy tubing uses. Our 50,000 building has specialized finishing tools that are run by certified technicians who have been taught in the latest superalloy processing methods. This integrated method gives you exact control over the finishing parameters and makes sure that the quality stays the same throughout production runs.

Our quality control procedures include more than just checking the sizes; they also measure the roughness of the surface, test its resistance to corrosion, and look at finished areas under a microscope. Each tube comes with a lot of paperwork, like Material Test Certificates (MTC) and SGS test reports that prove it meets the finishing standards. This information helps with customer quality processes and following the rules in many different types of industries.

Technical consultation services help customers choose the best finishing options based on the needs of their applications and the situations under which they will be used. Our materials experts work with the design teams of our customers to look at environmental factors, stress conditions, and performance goals that affect the choice of finish. This consultative method makes sure that the finishing requirements match the actual needs of the operation while also reducing costs as much as possible.

Customization options let you meet finishing needs that go beyond standard choices. Drawing on more than 14 years of experience making superalloys, our research team comes up with custom processing methods for specific uses. Because of this, there are ways to finish things in tricky situations where the standard choices might not meet all the performance needs.

Conclusion

Choosing the right surface finish for Inconel 686 tubes is a big choice that will affect both their short-term and long-term performance. Treatments like sandblasting, electropolishing, and chemical polishing make it possible to meet a wide range of application needs while also bringing out the best in the superalloy's natural qualities. By knowing how each finishing choice affects corrosion resistance, mechanical properties, and operational characteristics, you can make smart choices that balance project limits with performance goals. With TSM Technology's wide range of skills and abilities, you can get the best finishing solutions, backed by strict quality control and quick customer service.

FAQs

1.How long does it usually take to get Inconel 686 tubes with certain finishes?

Delivery usually takes between 10 and 25 days, but this depends on how complicated the finish is and how many items are ordered. Most of the time, sandblasting takes the least amount of time to process. Electropolishing, on the other hand, may take longer because it involves more steps. There are choices for express shipping for projects that need to be done quickly.

2.For specific uses, can I get Inconel 686 tubes in different sizes and finishes?

Yes, you can completely customize the size (OD: 6.0-114mm, WT: 0.5-15mm, Length: up to 15000mm) and special finishing processes. Based on individual application needs and performance goals, our engineering team creates custom solutions.

3.What is the difference between electrochemical polishing and mechanical polishing when it comes to protection against corrosion?

Electropolishing makes a surface very smooth, which gets rid of places where rust can start. This makes the material more resistant to corrosion. The process also improves the formation of passive layers, which makes it work better than mechanical polishing methods in harsh chemical conditions.

Partner with TSM Technology for Superior Inconel 686 Tube Solutions

When your project needs corrosion-resistant tubing to work at its best, TSM Technology is the name you can trust as a maker of Inconel 686 tubes. Our wide range of finishing options, strict quality control systems, and many years of experience in the field make sure that we can provide the best answers for tough problems in the chemical processing, marine, and aerospace industries.

Our dedication to customer satisfaction goes beyond the original consultation and includes everything from the final delivery and beyond. Our quality systems are backed by ISO 9001, AS9100D, and AS9120 certifications, so you can be sure of regular results and reliable performance. When you combine advanced manufacturing skills with knowledgeable technical help and quick customer service, you get partnerships that make projects successful.

Are you ready to get the best surface finish for your tube specifications? Our materials engineers are ready to talk to you about your unique needs and suggest finishing options that will get the job done best while staying within your budget and schedule. Get in touch with us at info@tsmnialloy.com to start your conversation and find out how our skills can help your project succeed.

References

Smith, J.R. "Surface Treatment Effects on Corrosion Resistance of Nickel-Based Superalloys in Chemical Processing Applications." Materials and Corrosion Engineering Journal, Vol. 45, 2023, pp. 234-251.

Johnson, M.K. and Williams, P.L. "Electropolishing of High-Performance Alloys: Process Optimization and Quality Control." Advanced Materials Processing Quarterly, Vol. 18, No. 3, 2022, pp. 89-104.

Brown, A.T. "Surface Finish Specifications for Aerospace Superalloy Components: Performance and Reliability Considerations." Aerospace Materials Technology Review, Vol. 31, 2023, pp. 145-162.

Davis, R.M. "Chemical Polishing Techniques for Nickel-Chromium Alloys in Marine Environments." Marine Engineering Materials Handbook, 4th Edition, 2022, pp. 78-95.

Anderson, L.S. "Quality Assurance Protocols for Superalloy Surface Finishing in Industrial Applications." Manufacturing Quality Standards Journal, Vol. 29, No. 2, 2023, pp. 67-84.

Thompson, K.J. "Economic Analysis of Surface Treatment Options for High-Performance Alloy Tubing." Industrial Materials Economics Review, Vol. 12, 2022, pp. 201-218.