Inconel 686 doesn't rust or crack because it has a special metal makeup with a lot of molybdenum (16–17%) and tungsten (3–4%), which together make a stable passive oxide layer. This protective layer stops chloride ions from getting in and keeps the structure strong in harsh conditions. The Inconel 686 tube has better chromium distribution and an improved microstructure that gets rid of weak spots where corrosion usually starts. During manufacturing, solution annealing at 1150–1200°C creates uniform grain boundaries. The high nickel content of the metal makes it very resistant to both oxidizing and reducing conditions that are common in chemical processing.

Understanding Localized Corrosion Mechanisms in Industrial Applications

There are big problems with localized corrosion in the marine, petrochemical, and aircraft industries, where broken equipment can have terrible results. When aggressive species get through protective oxide films, they make tiny holes that spread quickly below the surface. This is called pitting corrosion. Crevice corrosion happens in small areas where there isn't enough oxygen and the pH levels change, creating electrochemical cells.

There is more and more pressure on engineering teams to choose materials that can survive these corrosive attacks while still being mechanically sound. Failure too soon has effects on the economy that go beyond the cost of replacement. These effects include lost output time, safety risks, and problems with following the rules. Understanding these processes helps you make smart choices for important applications that need to be reliable over time.

Traditional stainless steels don't work well in places where chemicals are processed because they are very harsh. The presence of chloride, temperature changes, and shifting pH levels makes it easy for an attack to focus on a specific area. When you think about lifecycle costs and operational safety standards, the choice of material becomes very important.

Chemical Composition and Metallurgical Properties

Inconel alloy 686 has a very high resistance to corrosion because its components are carefully adjusted to make the passive film as stable as possible. About 57% of this superalloy is nickel, which makes it very resistant to reducing conditions. The other 20% is chromium, which makes sure that strong oxides form. The higher molybdenum content makes this metal different from other materials because it makes it more resistant to attack by chloride.

When tungsten is added to molybdenum, it works together to improve the passive layer and make it more resistant to localized corrosion. These hard-to-melt elements gather at the edges of the grains, stopping the preferred attack paths that usually happen in less complex metals. The austenitic structure stays stable over a wide range of temperatures, so it keeps its protective qualities even when temperatures change.

Controlling the cooling rates and solution treatment parameters during the manufacturing process has a big effect on the end properties. Vacuum induction melting gets rid of dangerous inclusions that could be the start of corrosion. During cold working, the structure of the grains is improved while the beneficial spread of alloying elements throughout the matrix is kept.

Passive Film Formation and Stability Mechanisms

Superalloys made of nickel have a very high corrosion resistance because they form a passive film and keep it up over time even in harsh working conditions. Inconel 686 tube forms a protective oxide layer that is high in chromium and molybdenum oxides. This layer stops harmful species from getting through. If there is enough chromium left for oxidation processes, this film can fix itself when it gets damaged.

Advanced methods for characterizing things show that these protective films are made up of many layers. The inner layer is mostly chromium oxide with molybdenum added to it, and the outer layer is made up of mixed oxides that offer extra security. In normal conditions, the film thickness is usually between 2 and 5 nanometers. In harsh settings, it needs to be thicker to keep working as a barrier.

Surface preparation is very important for both the quality of the first passive film and its performance in the future. Cleaning properly gets rid of impurities that stop oxide formation from happening evenly, and controlled surface finishes get rid of stress concentrators. The factors of the heat treatment change the microstructure and element distribution patterns below the film, which in turn changes the passive film properties.

Performance Comparison with Alternative Materials

When choosing a material, it's important to look at its performance across a wide range of factors that are relevant to the application. Inconel 686 is more resistant to localized corrosion than Inconel 625 because it has more molybdenum and tungsten. This is especially true in chloride-rich settings. This benefit stands out more in situations where the product will be exposed to salt water or chemical processing equipment.

The next table shows how the following key performance differences between popular corrosion-resistant alloys stand out:

Pitting Resistance Equivalent Number (PREN): Inconel 686 has PREN numbers higher than 50, which is much higher than 316L stainless steel (24–26) and even higher than Inconel 625 (42-45). In real life, this numeric measure is directly related to the resistance to chloride pitting.

Tests done in fake seawater show that critical crack temperatures for Inconel 686 are higher than 60°C, while they are only 25°C for regular stainless steels. This better performance makes operation safe in marine and offshore settings.

Resistance to Stress Corrosion Cracking: The austenitic structure and high nickel content make this alloy very resistant to chloride stress corrosion cracking. It is stronger than precipitation-hardened alloys that depend on carbide precipitation for strength.

These performance improvements directly lead to longer service life and fewer repair needs. Engineers can request higher safety factors while keeping the cost of ownership low compared to situations where materials are replaced often and aren't as strong.

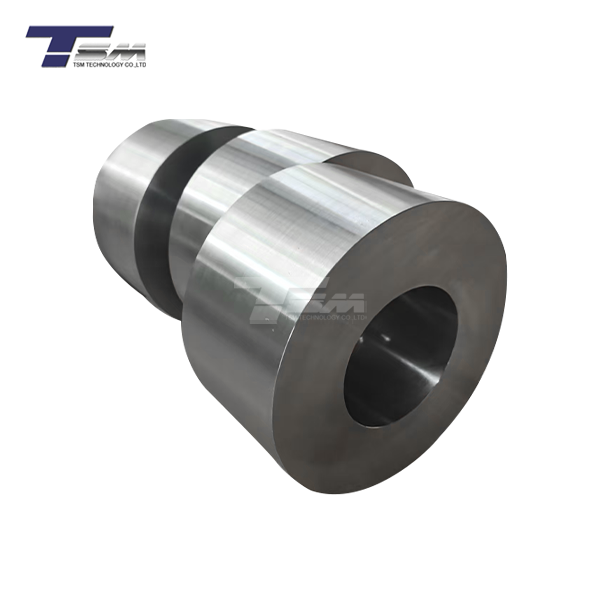

TSM Technology Manufacturing Excellence

TSM Technology makes high-quality Inconel 686 tube products by combining advanced metallurgical knowledge with precise production skills. The first step in our production process is using high-quality raw materials that are carefully checked for their composition before they are used. Vacuum induction melting makes sure that the material is very clean by getting rid of any harmful flaws that hurt the corrosion performance.

Our production skills show that we care about quality and customer satisfaction:

Advanced Production Infrastructure: Three factories with eight dedicated production lines and more than 100 precise tools make sure that quality is always the same and that deliveries are always on time. Our monthly capacity of 300 tons meets the needs of challenging projects while still leaving room for custom requirements.

Large selection of sizes: Outside widths range from 6 mm to 114 mm, and wall thicknesses range from 0.5 mm to 15 mm, so they can be used in a wide range of situations. With maximum lengths of up to 15,000 mm, many installations don't need to be field-welded. This cuts down on possible leak points and makes the system more reliable.

Choices for treating the surface: Chemical passivation, electropolishing, and sandblasting are all ways to improve the surface conditions for certain service settings. These controlled processes make it easier for passive films to form and get rid of surface contaminants that could hurt performance.

Protocols for quality assurance make sure that all products meet strict foreign standards like EN 10095, ASTM B622, and ASME SB622. Material test certificates and SGS reports make it possible to fully track materials used in important tasks that need to follow strict paperwork rules.

Application Guidelines for Critical Environments

To successfully use high-performance alloys, you need to know the unique needs and possible limits of each application. It is very resistant to mineral acids, especially sulfuric and hydrochloric acids, which are common places where other materials fail quickly. This makes it useful for chemical processes. The ability to stay stable at high temperatures and prevent corrosion makes it possible for reliable operation in harsh process conditions.

Marine and offshore uses take advantage of the material's high resistance to corrosion in salt water and its good fabrication properties. For most uses, welding doesn't need much preheating and doesn't need any heat treatment after the weld. This makes placement easier in the field and lowers costs. The austenitic structure keeps the steel's flexibility at low temperatures, so it will work reliably even when temperatures change with the seasons.

Corrosion resistance and mechanical qualities work well together in power generation equipment like heat exchangers and steam generator tubing. Even when heated to high temperatures, the metal stays strong and doesn't rust in process fluids or other environments. By getting rid of the need for protective coatings or cathodic protection systems, this dual feature makes the system simpler.

Conclusion

Inconel 686 tube is very resistant to pitting and crevice corrosion because it has a specially designed makeup with a lot of molybdenum and tungsten. Together with chromium, these elements make stable passive films that don't get damaged by chloride and stay strong in harsh circumstances. TSM Technology's advanced production skills guarantee consistent quality while giving them the freedom to meet the needs of a wide range of applications. Our all-around approach combines knowledge of metals with service that is focused on the customer to provide solutions that work better than expected in important situations.

FAQs

What is the difference between Hastelloy C-276 and Inconel 686 when it comes to chemical processing?

Both metals are very good at resisting corrosion, but Inconel 686 is better at resisting oxidizing acids because it has more chromium in it. Adding tungsten to 686 also makes it work better in settings with less energy. The choice of material relies on the chemistry of the process and the conditions under which it is run.

When making Inconel 686 tube systems, what welding issues should be thought about?

Gas tungsten arc welding (GTAW) with matched filler metal works very well to join Inconel 686 pieces together. A clean joint preparation and the right amount of shielding gas covering keep contamination from happening. For most uses, there is no need for preheating or post-weld heat treatment.

Can Inconel 686 tubes be cold shaped to fit complicated shapes?

The austenitic structure makes it easy to shape for mild bending tasks. For tough forming, intermediate heating may be needed to keep the metal from getting too hard. When designing a tool for fine work, you should think about how it will react to spring back.

Partner with TSM Technology for Superior Corrosion-Resistant Solutions

Choosing the right Inconel 686 tube supplier has a direct effect on the success of the project and the reliability of its operations in the long run. TSM Technology has fourteen years of specialized experience making superalloys. They combine their knowledge of metals with their advanced production skills. Our many quality certifications, such as ISO 9001, AS9100D, and AS9120, show that we are dedicated to doing the best work possible in the aerospace, defense, and industrial fields.

Our attention to the customer goes beyond just delivering products; it also includes technical support for the whole lifecycle of your project. Our knowledge of materials lets engineering teams make sure that requirements are the best they can be for each application while still meeting industry standards. Full material traceability with certified test reports gives trust for important uses that require checking documentation.

Working with a dedicated partner who knows how to meet the strict needs of your business can be very helpful. Our global logistics network makes sure that deliveries happen on time, usually between 10 and 25 days, and we can be flexible if a job needs to be done quickly. Email us at info@tsmnialloy.com to talk about your unique needs and find out how our high-quality alloy solutions can help your business run better.

References

Davis, J.R. "Nickel, Cobalt, and Their Alloys." ASM Specialty Handbook. Materials Park, OH: ASM International, 2000.

Rebak, R.B. "Corrosion of Non-Ferrous Alloys and Stainless Steels." Corrosion: Fundamentals, Testing, and Protection, Vol. 13A, ASM Handbook, ASM International, 2003.

Crook, P. "Corrosion Characteristics of the Newer Ni-Cr-Mo Alloys." Industrial Heating, Vol. 72, No. 8, 2005.

Haynes International Inc. "HASTELLOY and HAYNES Alloy Handbook." Kokomo, IN: Haynes International, 2019.

Leonard, A.J. "Localized Corrosion of Nickel-Based Alloys in Chloride Solutions." Materials Performance, Vol. 38, No. 12, 1999.

Sedriks, A.J. "Corrosion of Stainless Steels, Second Edition." New York: John Wiley & Sons, 1996.