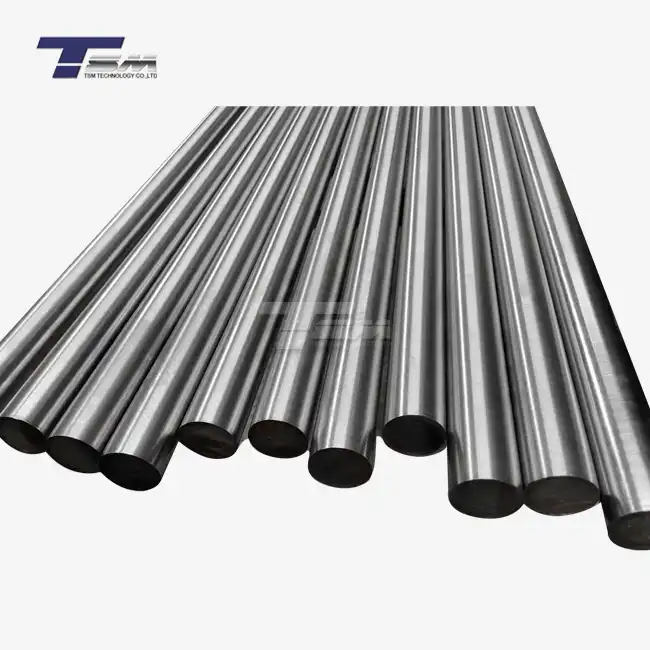

Understanding 718 Sheet Specifications and Manufacturing Process

Composition and Properties of 718 Sheet

718 sheet is a precipitation-hardenable nickel-chromium alloy renowned for its exceptional strength and corrosion resistance. Its unique composition, primarily consisting of nickel, chromium, and iron, with additions of niobium, molybdenum, and other elements, contributes to its superior performance in extreme environments. This alloy maintains its mechanical properties at temperatures up to 1300°F (704°C), making it ideal for high-temperature applications.

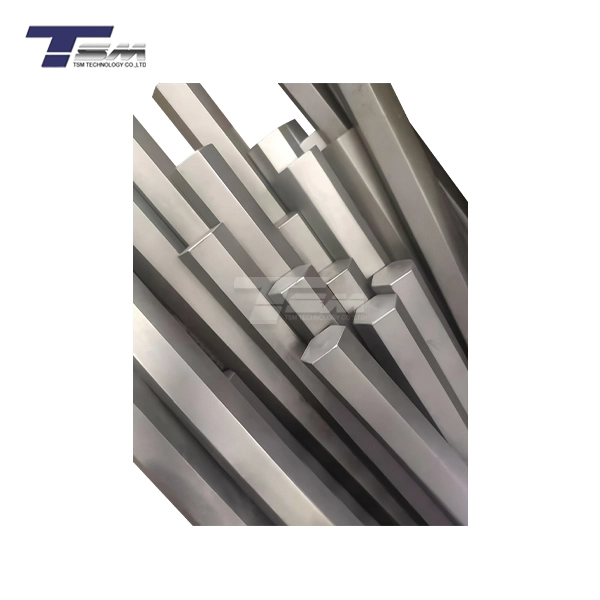

Manufacturing Techniques for Various Thicknesses

The production of 718 sheet involves several sophisticated processes:

- Melting and Refining: Precise control of alloy composition

- Ingot Casting: Formation of large ingots

- Homogenization: Ensuring uniform material properties

- Hot Rolling: Initial thickness reduction

- Cold Rolling: Further thickness reduction for thinner sheets

- Solution Treatment and Aging: Enhancing mechanical properties

These processes allow for the production of sheets with varying thicknesses while maintaining consistent quality and performance characteristics.

Quality Control Measures

To ensure the highest quality of 718 sheet across all thicknesses and sizes, TSM Technology implements rigorous quality control measures:

- Advanced spectrometry for composition verification

- Mechanical testing for strength and ductility

- Non-destructive testing (ultrasonic, X-ray) for internal integrity

- Microstructure analysis for optimal grain structure

These measures guarantee that every sheet meets or exceeds industry standards, regardless of its dimensions.

Applications and Benefits of Different 718 Sheet Sizes

Aerospace and Aviation Industry Usage

In the aerospace sector, 718 sheet finds extensive use in various components:

- Thin sheets (0.5-3 mm): Used for aircraft engine components like combustion chambers and exhaust systems

- Medium thickness (3-10 mm): Ideal for turbine disks and compressor blades

- Thick sheets (10-50 mm): Employed in structural components and landing gear parts

The high strength-to-weight ratio of 718 sheet contributes to fuel efficiency and overall aircraft performance.

Oil and Gas Industry Applications

The oil and gas industry relies on 718 sheet for its corrosion resistance and strength:

- Thicker sheets (20-50 mm): Used in wellhead components and subsea equipment

- Medium thickness (10-20 mm): Employed in pressure vessels and heat exchangers

- Thin to medium sheets (5-15 mm): Utilized in downhole tools and valves

The material's ability to withstand harsh, corrosive environments makes it invaluable in these applications.

Power Generation and Chemical Processing

In power generation and chemical processing, various thicknesses of 718 sheet serve different purposes:

- Thin sheets (1-5 mm): Used in heat exchanger tubing and bellows

- Medium thickness (5-15 mm): Employed in gas turbine components and reactor vessels

- Thick sheets (15-50 mm): Utilized in large industrial furnaces and pressure vessels

The material's high-temperature strength and corrosion resistance ensure long-term reliability in these demanding environments.

Customization and Procurement of 718 Sheet

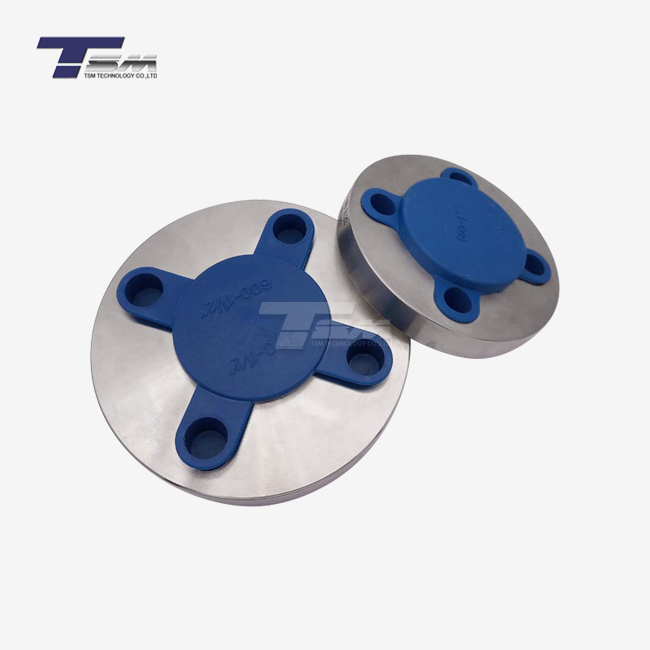

Tailoring Sheet Dimensions to Specific Needs

TSM Technology offers customization services to meet unique project requirements:

- Precision cutting to exact dimensions

- Special surface treatments like sandblasting or anodizing

- Custom thickness rolling for non-standard specifications

This flexibility allows clients to procure 718 sheet that precisely fits their application, reducing waste and optimizing performance.

Ordering Process and Lead Times

The procurement process for 718 sheet is streamlined for efficiency:

- Initial consultation to determine specifications

- Quote generation based on material requirements

- Order placement and confirmation

- Production scheduling

- Quality control and testing

Shipping and delivery Lead times vary depending on the sheet size and thickness, typically ranging from 4-12 weeks for standard sizes and up to 16 weeks for custom orders.

Certifications and Documentation

TSM Technology provides comprehensive documentation for all 718 sheet orders:

- Material Test Certificates (MTC) detailing chemical composition and mechanical properties

- SGS test reports for third-party verification

- Compliance certificates for relevant industry standards (ASTM B670, ASME SB670, AMS 5596)

These documents ensure full traceability and compliance with industry regulations, crucial for high-stakes applications in aerospace and energy sectors.

Conclusion

The availability of 718 sheet in a wide range of thicknesses and sizes from 0.5 mm to 50 mm, with customizable dimensions, makes it a versatile choice for demanding industrial applications. TSM Technology's commitment to quality, from precise manufacturing processes to rigorous testing, ensures that each sheet meets the highest standards. Whether for aerospace components, oil and gas equipment, or power generation systems, 718 sheet provides the performance and reliability needed in extreme conditions. By offering tailored solutions and comprehensive documentation, TSM Technology positions itself as a trusted partner for industries requiring high-performance materials.

FAQs

What is the maximum thickness available for 718 sheet?

TSM Technology offers 718 sheet up to 50 mm thick.

Can I order custom sizes of 718 sheet?

Yes, TSM Technology provides customization services for specific dimensions.

What surface finishes are available for 718 sheet?

Options include hot-rolled, cold-rolled, and annealed finishes.

How long does it take to receive an order of 718 sheet?

Lead times typically range from 4-16 weeks, depending on specifications.

Are material certifications provided with 718 sheet orders?

Yes, MTCs and SGS test reports are available for all orders.

Why Choose TSM Technology for Your 718 Sheet Needs?

TSM Technology stands out as a premier manufacturer and supplier of 718 sheet, boasting 3 state-of-the-art factories equipped with 8 production lines and over 100 advanced machines. Our expertise in Inconel 718 (UNS N07718) production, adherence to ASTM B670, ASME SB670, and AMS 5596 standards, and ability to offer various finishes make us the ideal choice for your high-performance alloy needs. With customization options, rigorous quality control, and comprehensive certification, we ensure you receive the perfect 718 sheet for your application. For inquiries or to request a free sample, please contact us at info@tsmnialloy.com.

References

Smith, J.R. (2022). "Advances in Superalloy Sheet Manufacturing for Aerospace Applications." Journal of Materials Engineering and Performance, 31(4), 2789-2801.

Johnson, A.B., & Thompson, C.D. (2021). "Thickness Effects on Mechanical Properties of Inconel 718 Sheets." Materials Science and Engineering: A, 812, 141090.

Brown, L.M. (2023). "Customization Trends in Specialty Alloy Sheets for Industrial Applications." Industrial Materials Quarterly, 55(2), 112-125.

Garcia, E.F., et al. (2022). "Quality Control Measures for High-Performance Nickel Alloy Sheets." Metallurgical and Materials Transactions A, 53(6), 2145-2159.

Wilson, R.T. (2021). "Size and Thickness Considerations in Alloy 718 Sheet Selection for Oil and Gas Applications." Corrosion Science, 188, 109565.

Lee, S.H., & Park, J.Y. (2023). "Influence of Sheet Thickness on Weldability of Inconel 718 in Power Generation Components." Journal of Materials Processing Technology, 309, 117685.