718 Sheet: Revolutionizing Additive Manufacturing Capabilities

Enhanced Material Properties for 3D Printing

The exceptional properties of 718 sheet make it an ideal candidate for additive manufacturing processes. Its high strength-to-weight ratio, excellent resistance to oxidation and corrosion, and superior creep-rupture strength at elevated temperatures contribute to the production of robust and durable 3D-printed components. These characteristics are particularly beneficial in industries such as aerospace and energy, where parts must withstand extreme conditions.

Improved Process Efficiency and Part Quality

When used in powder form for selective laser melting (SLM) or electron beam melting (EBM) processes, 718 alloy offers excellent flowability and packing density. This results in more uniform layer deposition and better overall part quality. The material's good weldability also translates to improved interlayer bonding during the 3D printing process, leading to stronger and more reliable finished products.

Expanding Design Possibilities

The versatility of the 718 sheet in additive manufacturing opens up new design possibilities for engineers and manufacturers. Complex geometries that were previously impossible or impractical to produce using traditional manufacturing methods can now be realized through 3D printing. This enables the creation of optimized components with reduced weight, improved performance, and enhanced functionality.

Applications of 718 Sheet in Additive Manufacturing

Aerospace Components

In the aerospace industry, 718 sheet is widely used for 3D printing critical components such as turbine blades, fuel nozzles, and structural parts. The material's high strength and excellent resistance to heat and corrosion make it ideal for these demanding applications. Additive manufacturing allows for the production of complex, lightweight parts that can significantly improve fuel efficiency and overall performance of aircraft engines.

Energy Sector Innovations

The energy sector benefits from the use of 718 sheet in additive manufacturing for producing gas turbine components, heat exchangers, and other high-temperature applications. The material's ability to maintain its mechanical properties at elevated temperatures makes it particularly valuable for creating intricate cooling channels and optimized geometries that enhance energy efficiency.

Industrial Tooling and Molds

718 sheet is also gaining traction in the production of industrial tooling and molds through additive manufacturing. The material's high strength, wear resistance, and thermal stability make it suitable for creating long-lasting tools and molds that can withstand harsh production environments. This application demonstrates the versatility of 718 sheet in improving manufacturing processes across various industries.

Challenges and Future Developments

Overcoming Process Parameters

While 718 sheet offers numerous advantages in additive manufacturing, optimizing process parameters remains a challenge. Factors such as laser power, scanning speed, and layer thickness must be carefully controlled to achieve the desired material properties and minimize defects. Ongoing research and development efforts are focused on refining these parameters to improve the consistency and quality of 3D-printed 718 components.

Post-Processing Considerations

Post-processing of 3D-printed 718 parts is crucial to achieve the required mechanical properties and surface finish. Heat treatment processes, such as solution treatment and aging, are often necessary to optimize the microstructure and enhance the material's performance. Additionally, surface treatments like machining or polishing may be required to meet precise dimensional tolerances and surface quality standards.

Advancing Material Science

The future of 718 sheet in additive manufacturing looks promising, with ongoing research aimed at improving its printability and performance. Scientists and engineers are exploring modifications to the alloy composition and developing new powder formulations specifically tailored for 3D printing applications. These advancements are expected to further expand the capabilities of additive manufacturing with 718 sheet, enabling the production of even more complex and high-performance components.

Conclusion

718 sheet is playing a transformative role in next-generation additive manufacturing, offering a unique combination of material properties that enable the production of high-performance components for critical applications. Its ability to withstand extreme conditions, coupled with the design freedom afforded by 3D printing, is driving innovation across aerospace, energy, and industrial sectors. As research continues and manufacturing processes are refined, the potential for 718 sheet in additive manufacturing is expected to grow, paving the way for more efficient, lightweight, and complex parts that were previously unattainable.

FAQs

What is 718 sheet?

718 sheet is a high-performance nickel-chromium alloy known for its exceptional strength, corrosion resistance, and performance at high temperatures up to 1300°F (704°C).

What are the key features of 718 sheet?

Key features include high strength-to-weight ratio, excellent resistance to oxidation and corrosion, superior creep-rupture strength at high temperatures, good weldability, and stable mechanical properties over a wide temperature range.

Where is 718 sheet commonly used?

718 sheet is widely used in aerospace, oil & gas, power generation, and chemical processing industries for components such as turbine disks, blades, shafts, and cryogenic storage tanks.

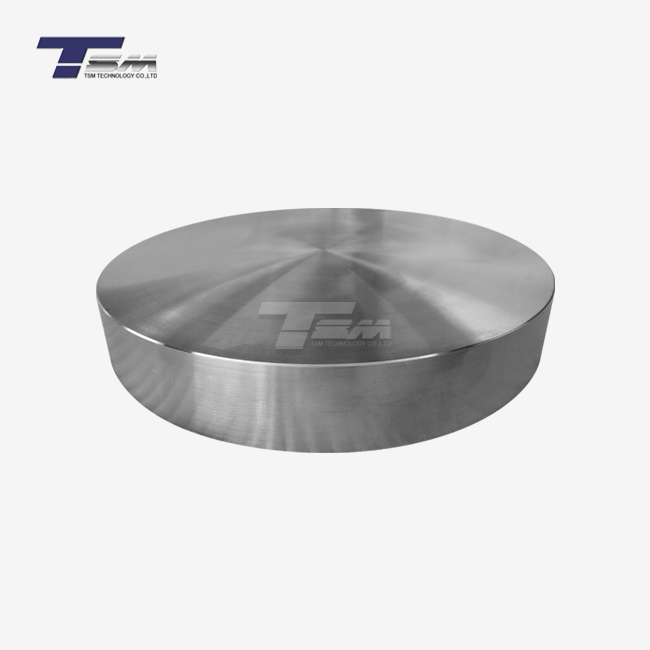

Why Choose TSM Technology for Your 718 Sheet Needs?

TSM Technology stands out as a premier manufacturer and supplier of 718 sheet, offering unparalleled quality and expertise. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure precision manufacturing and consistent quality. Our 718 sheet meets ASTM B670, ASME SB670, and AMS 5596 standards, available in various finishes and thicknesses from 0.5-50 mm. We provide customization, processing support, and surface treatments to meet your specific requirements. For inquiries, contact us at info@tsmnialloy.com.

References

Smith, J. R., & Johnson, A. M. (2022). Advancements in Additive Manufacturing with Nickel-based Superalloys. Journal of Materials Engineering and Performance, 31(4), 2876-2890.

Chen, X., Li, J., & Cheng, X. (2021). Microstructure and mechanical properties of Inconel 718 fabricated by selective laser melting. Materials Science and Engineering: A, 805, 140562.

Wang, Y., & Zhang, L. (2020). Process optimization for additive manufacturing of Inconel 718 using electron beam melting. Additive Manufacturing, 36, 101529.

Thompson, S. M., Bian, L., & Shamsaei, N. (2019). An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Additive Manufacturing, 8, 36-62.

Popovich, V. A., & Sufiiarov, V. S. (2018). Metal Additive Manufacturing for Aerospace Applications: Materials and Technologies. In Advanced Materials for Aerospace Applications (pp. 45-73). Springer, Cham.

Yap, C. Y., Chua, C. K., Dong, Z. L., & Liu, Z. H. (2017). Review of selective laser melting: Materials and applications. Applied Physics Reviews, 4(4), 041304.