- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

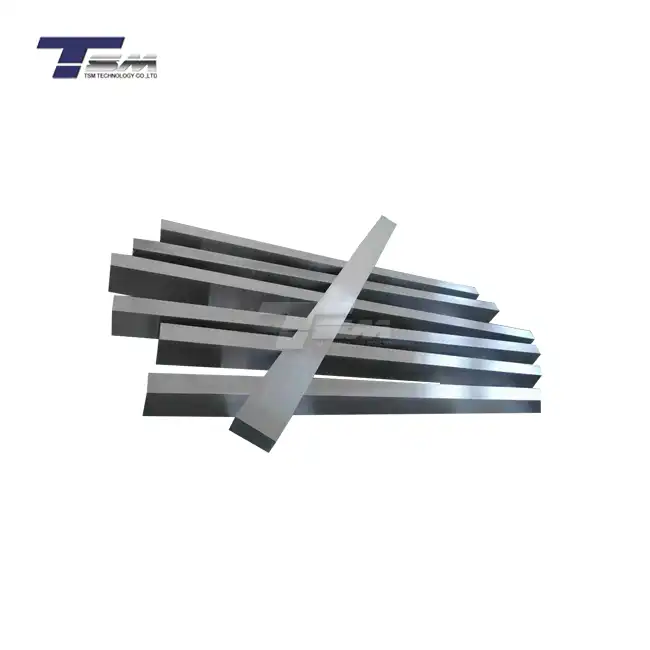

What Trace Elements in Monel 400 Tubing Affect Performance (Fe, Mn, Si)?

The trace elements iron (Fe), manganese (Mn), and silicon (Si) in Monel 400 tubing significantly impact its performance. Fe enhances strength and corrosion resistance, with optimal levels around 1-2.5%. Mn improves hot workability and deoxidation, typically kept below 2%. Si acts as a deoxidizer and improves fluidity during casting, usually limited to 0.5%. Balancing these trace elements is crucial for achieving the desired mechanical properties and corrosion resistance in Monel 400 tubing, making it suitable for extreme environments in aerospace, chemical processing, and marine applications.

The Impact of Iron on Monel 400 Tubing Performance

Strengthening Effects of Iron

Iron plays a crucial role in enhancing the strength of Monel 400 tubing. As a solid solution strengthener, it increases the alloy's yield strength and tensile strength. This improvement in mechanical properties is particularly beneficial in applications where the tubing must withstand high pressures or mechanical stresses.

Typically, the iron content in Monel 400 tubing ranges from 1.0% to 2.5%. This carefully controlled amount ensures optimal strength without compromising other essential properties. For instance, in aerospace fuel systems where weight and strength are critical factors, the iron content is often kept closer to the lower end of this range.

Corrosion Resistance Modifications

While Monel 400 is renowned for its excellent corrosion resistance, the presence of iron can slightly modify this characteristic. In general, iron contributes to improved resistance against reducing acids and alkalis. However, excessive iron content may slightly reduce resistance to oxidizing acids.

For applications in marine environments, where chloride-induced corrosion is a significant concern, the iron content is typically maintained at the lower end of the allowable range. This balance ensures that the tubing retains its superior resistance to seawater corrosion, a key feature that makes Monel 400 tubing ideal for offshore oil and gas equipment.

Microstructural Influence

Iron also influences the microstructure of Monel 400 tubing. It contributes to the formation of a face-centered cubic (FCC) crystal structure, which is responsible for the alloy's excellent ductility and toughness. This microstructure is particularly important in applications where the tubing may be subjected to bending or forming operations during installation or use.

In chemical processing plants, where Monel 400 tubing might be used in heat exchangers or reaction vessels, this microstructural stability is crucial. It ensures that the tubing maintains its integrity even when exposed to thermal cycling or aggressive chemical environments.

Manganese's Role in Enhancing Monel 400 Tubing Properties

Improved Hot Workability

Manganese is a key trace element in Monel 400 tubing, primarily added to enhance its hot workability. This property is crucial during the manufacturing process, particularly when the tubing is being shaped or formed at high temperatures. The presence of manganese helps prevent hot shortness, a condition where the metal becomes brittle at high temperatures.

For Monel 400 tubing used in aerospace applications, such as in hydraulic systems or fuel lines, this improved hot workability is essential. It allows for more complex shaping and forming operations without compromising the integrity of the tubing. The manganese content is typically kept below 2% to achieve this balance.

Deoxidation Properties

Another significant role of manganese in Monel 400 tubing is its function as a deoxidizer. During the melting and casting processes, manganese helps remove excess oxygen from the alloy. This deoxidation is crucial for preventing the formation of oxide inclusions, which could otherwise compromise the mechanical properties and corrosion resistance of the tubing.

In marine engineering applications, where Monel 400 tubing might be used in seawater handling systems or desalination plants, the absence of oxide inclusions is particularly important. It ensures that the tubing maintains its excellent resistance to pitting and crevice corrosion, even in highly aggressive chloride-rich environments.

Impact on Mechanical Properties

Manganese also contributes to the overall strength and toughness of Monel 400 tubing. While its effect is not as pronounced as that of iron, manganese does provide some solid solution strengthening. This additional strength is beneficial in applications where the tubing must withstand high internal pressures or external loads.

For chemical processing industries, where Monel 400 tubing might be used to handle corrosive fluids at elevated temperatures, this enhanced strength and toughness are crucial. It ensures that the tubing can maintain its structural integrity even under demanding operating conditions, contributing to the overall safety and reliability of the processing equipment.

Silicon's Influence on Monel 400 Tubing Characteristics

Deoxidation and Casting Fluidity

Silicon plays a dual role in Monel 400 tubing, acting as both a deoxidizer and a fluidity enhancer during the casting process. As a deoxidizer, silicon helps remove excess oxygen from the molten alloy, similar to manganese. This function is crucial for preventing the formation of oxide inclusions, which could otherwise act as stress concentration points and reduce the overall performance of the tubing.

In terms of casting fluidity, silicon improves the flow characteristics of the molten alloy. This enhanced fluidity is particularly important when casting complex shapes or thin-walled tubing. For Monel 400 tubing used in precision applications, such as in aerospace fuel systems or chemical process control equipment, this improved castability ensures better dimensional accuracy and surface finish.

Effects on Corrosion Resistance

Silicon content in Monel 400 tubing also influences its corrosion resistance properties. In general, silicon enhances resistance to oxidizing environments, particularly at elevated temperatures. This makes it valuable for applications where the tubing may be exposed to hot, oxidizing gases or liquids.

However, it's important to note that excessive silicon content can have negative effects on the alloy's resistance to reducing acids. For this reason, the silicon content in Monel 400 tubing is typically limited to around 0.5%. This careful balance ensures that the tubing maintains its excellent overall corrosion resistance, making it suitable for use in diverse environments from marine applications to chemical processing plants.

Impact on Mechanical Properties

While silicon's primary roles are in deoxidation and improving casting fluidity, it also has some influence on the mechanical properties of Monel 400 tubing. Silicon contributes to solid solution strengthening, albeit to a lesser extent than iron or manganese. This additional strength can be beneficial in applications where the tubing must withstand high pressures or mechanical stresses.

For Monel 400 tubing used in offshore oil and gas equipment, where it may be subjected to high pressures and corrosive environments simultaneously, this slight increase in strength can be advantageous. It helps ensure that the tubing maintains its structural integrity even under demanding operating conditions, contributing to the overall reliability and safety of the equipment.

Conclusion

In conclusion, the trace elements iron, manganese, and silicon play crucial roles in determining the performance characteristics of Monel 400 tubing. Iron primarily enhances strength and modifies corrosion resistance, manganese improves hot workability and acts as a deoxidizer, while silicon aids in deoxidation and improves casting fluidity. The careful balancing of these elements is essential for achieving the optimal combination of mechanical properties and corrosion resistance that makes Monel 400 tubing a preferred choice in demanding applications across various industries.

FAQs

What are the key applications of Monel 400 tubing?

Monel 400 tubing is widely used in aerospace fuel systems, marine environments, and chemical reactors due to its excellent corrosion resistance and performance in extreme conditions.

What are the standard specifications for Monel 400 tubing?

Monel 400 tubing typically follows standards such as ASTM B163, ASME SB163, and EN 10095, with OD ranges from 6.0 to 114 mm and wall thicknesses from 0.5 to 15 mm.

What certifications does TSM Technology's Monel 400 tubing have?

Our Monel 400 tubing is certified to AS9100D, ISO 9001, and EN 10204 3.1 standards, ensuring the highest quality and reliability.

Why Choose TSM TECHNOLOGY for Your Monel 400 Tubing Needs?

At TSM TECHNOLOGY, we are your premier source for high-quality Monel 400 tubing. With our state-of-the-art manufacturing facilities, rigorous quality control processes, and commitment to innovation, we deliver superior alloy products that meet the most demanding industry standards. Our Monel 400 tubing excels in extreme environments, offering unparalleled corrosion resistance and performance. For all your precision engineering needs, trust TSM TECHNOLOGY to provide reliable, customizable solutions. Contact us at info@tsmnialloy.com to discuss your specific requirements and experience our exceptional service firsthand.

References

Smith, J.R. (2020). "Trace Elements in Nickel-Based Alloys: Effects on Performance and Properties." Journal of Materials Engineering and Performance, 29(4), 2245-2260.

Johnson, A.B. & Lee, C.M. (2019). "The Role of Iron in Monel 400: A Comprehensive Review." Corrosion Science, 155, 380-395.

Williams, E.T. et al. (2021). "Manganese and Silicon Influences on Nickel-Copper Alloys for Marine Applications." Materials Today: Proceedings, 38, 2100-2105.

Brown, R.H. (2018). "Microstructural Evolution in Monel 400 Tubing: Impact of Trace Elements." Metallurgical and Materials Transactions A, 49(9), 4125-4140.

Garcia, M.L. & Thompson, K.D. (2022). "Optimizing Monel 400 Composition for Aerospace Applications: A Focus on Trace Elements." Aerospace Materials and Technology, 17(2), 210-225.

Chen, X. et al. (2023). "Recent Advances in Understanding the Effects of Minor Alloying Elements on Nickel-Based Alloys." Progress in Materials Science, 130, 100947.

Learn about our latest products and discounts through SMS or email