Understanding the Unique Properties of Alloy 718 Sheet

Composition and Microstructure

Alloy 718 sheet is a high-performance, precipitation-hardenable nickel-chromium alloy specifically engineered for superior mechanical and thermal stability. Its composition typically includes nickel as the base element, combined with chromium, iron, niobium, and molybdenum, along with smaller additions of titanium and aluminum. These elements work synergistically to form a finely distributed gamma prime (γ′) and gamma double prime (γ″) precipitate structure during heat treatment. This stable microstructure enhances the alloy's strength, creep resistance, and structural integrity, even when subjected to prolonged exposure at elevated temperatures.

Strength and Durability

A defining characteristic of Alloy 718 sheet is its exceptional combination of strength, toughness, and low density, which provides a high strength-to-weight ratio. This property makes it an indispensable material in the aerospace industry, where minimizing weight without compromising performance is essential. The alloy retains its mechanical strength up to approximately 700°C (1290°F), resisting deformation under high stress. Additionally, its excellent fatigue and creep resistance enable long-term reliability in jet engine components, gas turbines, and other high-temperature structural assemblies.

Corrosion and Oxidation Resistance

Alloy 718 sheet demonstrates outstanding resistance to corrosion and oxidation, key requirements for aerospace and industrial applications exposed to aggressive environments. The high chromium and nickel content form a stable passive oxide layer that protects the material from chemical attack and oxidation at elevated temperatures. It also exhibits strong resistance to pitting, stress corrosion cracking, and chloride-induced degradation. These properties make Alloy 718 ideal for use in turbine casings, exhaust systems, and fasteners, where both structural performance and environmental durability are critical for long-term operational safety and efficiency.

Applications of Alloy 718 Sheet in Aerospace Structures

Jet Engine Components

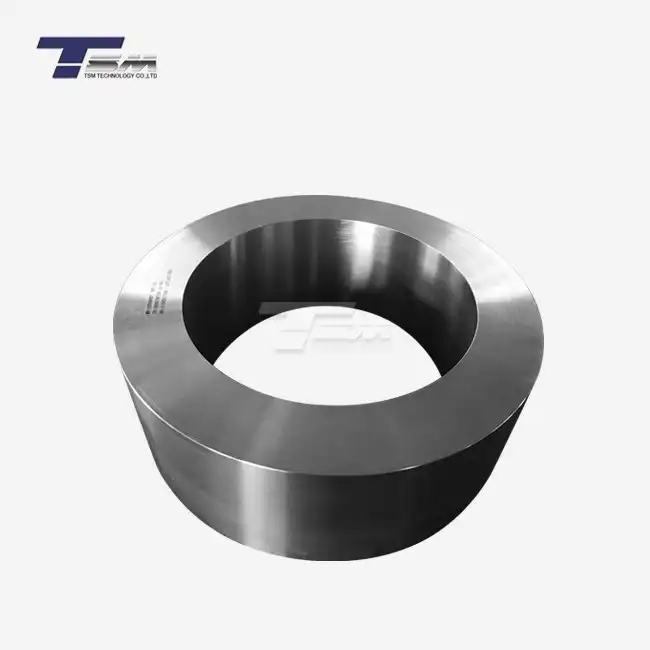

Alloy 718 sheet is a cornerstone material in the production of advanced jet engine components due to its superior strength and thermal stability. It is commonly used in turbine disks, compressor blades, and combustion chamber liners, where materials must endure high rotational speeds and extreme heat. The alloy's outstanding creep resistance and fatigue performance ensure reliable operation over long service intervals. Furthermore, its weldability and formability allow for precise manufacturing of complex geometries essential for maintaining aerodynamic efficiency and engine durability.

Structural Elements in Aircraft

Beyond propulsion systems, Alloy 718 sheet plays a vital role in the construction of critical aircraft structures requiring both high strength and fatigue resistance. It is widely applied in the fabrication of fasteners, support brackets, and reinforcing panels that experience significant mechanical loads during flight. The material's excellent toughness, even at cryogenic temperatures, enhances structural reliability under dynamic stress conditions. Its ability to resist corrosion and oxidation further contributes to reduced maintenance requirements and longer service life in modern aerospace designs.

Space Vehicle Applications

Alloy 718 sheet has proven indispensable in the demanding environment of space exploration, where materials must endure extreme thermal cycles, vacuum conditions, and mechanical vibration. It is used in rocket engine parts, cryogenic fuel system components, and satellite structural panels that require both lightweight and exceptional strength retention. The alloy's resistance to oxidation and radiation damage ensures consistent performance during prolonged space missions. Its dimensional stability and weldability make it a preferred choice for aerospace manufacturers developing next-generation launch systems and orbital platforms.

Manufacturing and Processing of Alloy 718 Sheet

Production Techniques

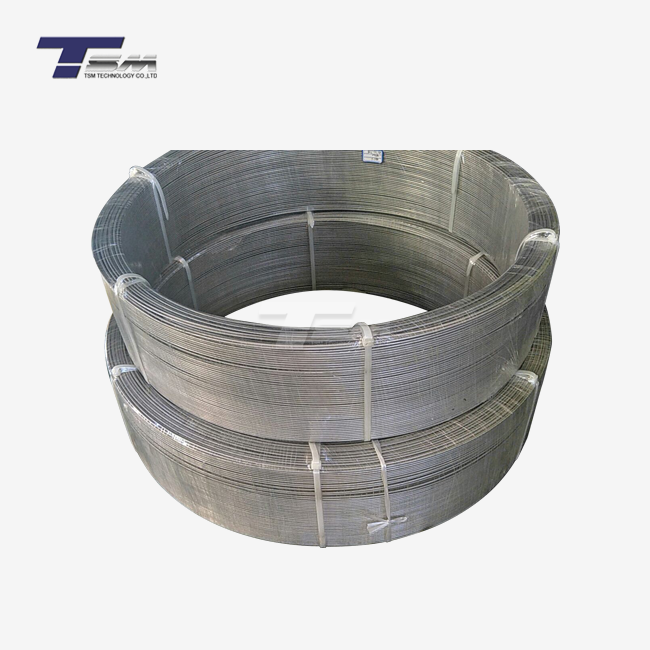

The manufacturing process of Alloy 718 sheet involves a series of carefully controlled stages designed to ensure consistent quality and performance. It begins with vacuum induction melting (VIM) or vacuum arc remelting (VAR) to achieve high purity and uniform composition. The resulting ingots are then homogenized to eliminate segregation and improve workability. Subsequent hot rolling refines the grain structure and enhances mechanical strength, while optional cold rolling provides tighter dimensional tolerances and surface finish improvements. These steps collectively ensure the alloy's superior formability and stability for demanding aerospace applications.

Heat Treatment

Heat treatment plays a pivotal role in achieving the desired microstructure and mechanical characteristics of Alloy 718 sheet. The process typically involves solution annealing at elevated temperatures to dissolve alloying elements, followed by rapid cooling to lock in the homogeneous structure. Aging treatments are then applied to promote the precipitation of strengthening phases, particularly the gamma-prime (γ′) and gamma-double-prime (γ″) phases. These precipitates significantly enhance yield strength, hardness, and creep resistance. Precise temperature and time control during heat treatment are critical for ensuring optimal performance under high-stress and high-temperature conditions.

Quality Control Measures

Maintaining stringent quality control throughout the production of Alloy 718 sheet is essential, particularly for aerospace and high-performance engineering applications. Each batch is subject to full traceability from raw materials to final inspection. Advanced spectrometric analysis verifies chemical composition compliance with AMS and ASTM standards. Mechanical testing—such as tensile, hardness, and impact evaluations—ensures the material meets strength and ductility requirements. Non-destructive testing methods, including ultrasonic and eddy current inspections, detect internal defects or inconsistencies. These comprehensive checks guarantee that every sheet delivers the reliability and safety demanded by critical aerospace systems.

Conclusion

Alloy 718 sheet stands out as an exceptional material for high-temperature aerospace structures. Its unique combination of strength, corrosion resistance, and thermal stability makes it invaluable in the most demanding aerospace applications. From jet engine components to space vehicle structures, this versatile alloy continues to play a crucial role in advancing aerospace technology. As the industry pushes the boundaries of performance and efficiency, Alloy 718 sheet remains a reliable choice for engineers and manufacturers seeking to meet the challenges of modern aerospace design.

FAQs

What is the maximum operating temperature for Alloy 718 sheet?

Alloy 718 sheet can perform effectively at temperatures up to 1300°F (704°C).

Is Alloy 718 sheet suitable for welding?

Yes, Alloy 718 sheet exhibits good weldability, making it suitable for fabricating complex aerospace structures.

What are the key advantages of using Alloy 718 sheet in aerospace applications?

The main advantages include high strength-to-weight ratio, excellent corrosion resistance, superior creep-rupture strength at high temperatures, and stable mechanical properties over a wide temperature range.

Why Choose TSM TECHNOLOGY for Your Alloy 718 Sheet Needs?

TSM TECHNOLOGY is your trusted partner for high-quality Alloy 718 sheet. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure precision manufacturing and consistent quality. Our products meet rigorous standards such as ASTM B670, ASME SB670, and AMS 5596. We offer customization, various surface treatments, and comprehensive material certifications. Choose TSM TECHNOLOGY for reliable, high-performance Alloy 718 sheet tailored to your aerospace needs. Contact us at info@tsmnialloy.com for more information or to request a free sample.

References

Smith, J.R., "Advanced Materials in Aerospace Engineering: A Comprehensive Review", Journal of Aerospace Materials, Vol. 45, No. 3, 2022.

Johnson, A.B., "High-Temperature Properties of Nickel-Based Superalloys", Materials Science and Engineering: A, Vol. 678, 2021.

Brown, C.D., "Alloy 718: Microstructure and Mechanical Properties", Superalloys: Processing and Performance, Springer, 2020.

Davis, E.F., "Fabrication Techniques for Aerospace Alloys", Aerospace Manufacturing Technology, Vol. 33, No. 2, 2023.

Wilson, G.H., "Corrosion Resistance of Nickel-Based Alloys in Extreme Environments", Corrosion Science, Vol. 89, 2022.

Thompson, R.L., "Heat Treatment Optimization for Alloy 718 in Aerospace Applications", Heat Treatment and Surface Engineering, Vol. 12, No. 4, 2021.