Understanding the Creep Behavior of 718 Sheet at High Temperatures

Microstructural Stability and Its Impact on Creep Resistance

The exceptional creep resistance of 718 sheet at 1300 °F is largely attributed to its stable microstructure. The alloy's composition, primarily consisting of nickel, chromium, and iron, along with carefully controlled additions of niobium, molybdenum, and aluminum, allows for the formation of strengthening precipitates. These precipitates, predominantly γ'' (Ni3Nb) and γ' (Ni3(Al,Ti)), remain stable at high temperatures, effectively pinning dislocations and inhibiting grain boundary sliding.

The stability of these precipitates is crucial for maintaining the alloy's strength over extended periods at elevated temperatures. As a result, 718 sheet exhibits minimal creep deformation, even under sustained stress at 1300 °F. This microstructural stability ensures that components made from 718 sheet maintain their dimensional accuracy and structural integrity in high-temperature environments, making it an ideal choice for applications in gas turbines and aerospace engines.

Time-Dependent Deformation Mechanisms in 718 Sheet

At 1300 °F, 718 sheet undergoes time-dependent deformation through various mechanisms. The primary creep mechanism at this temperature is dislocation creep, where the movement of dislocations within the crystal structure leads to gradual deformation. However, the presence of fine, coherent precipitates in 718 sheet significantly impedes dislocation motion, resulting in a low creep rate.

Another important mechanism is grain boundary sliding, which becomes more pronounced at higher temperatures. The alloying elements in 718 sheet, particularly boron and zirconium, segregate to grain boundaries, strengthening them and reducing the propensity for grain boundary sliding. This further enhances the alloy's creep resistance at 1300 °F, allowing it to maintain its structural integrity under prolonged stress.

Creep Rate and Rupture Life of 718 Sheet at 1300 °F

The creep rate of 718 sheet at 1300 °F is remarkably low, typically on the order of 10^-8 to 10^-9 per hour under typical service stresses. This low creep rate translates to excellent dimensional stability over extended periods, which is crucial for maintaining tight tolerances in critical components.

The rupture life of 718 sheet at 1300 °F is also impressive, often exceeding 10,000 hours under moderate stresses. This long rupture life is a testament to the alloy's ability to withstand prolonged exposure to high temperatures and stresses without failure. The combination of low creep rate and high rupture life makes 718 sheet an ideal material for long-term, high-temperature applications in aerospace and power generation industries.

Fatigue Performance of 718 Sheet in Extreme Conditions

High-Temperature Fatigue Mechanisms in 718 Sheet

At 1300 °F, the fatigue behavior of 718 sheet is governed by complex mechanisms that differ from those at room temperature. The primary fatigue mechanism at this elevated temperature is creep-fatigue interaction. Under cyclic loading, the material experiences both time-dependent creep deformation and cycle-dependent fatigue damage. The interaction between these two processes can lead to accelerated crack initiation and propagation.

However, 718 sheet's unique microstructure provides significant resistance to these high-temperature fatigue mechanisms. The fine, coherent precipitates that strengthen the alloy also serve to impede crack propagation. Additionally, the high-temperature stability of these precipitates ensures that the alloy maintains its fatigue resistance even after prolonged exposure to 1300 °F.

Cyclic Stress-Strain Response of 718 Sheet at 1300 °F

The cyclic stress-strain response of 718 sheet at 1300 °F exhibits characteristics of both high-temperature deformation and cyclic hardening. Initially, the alloy may show some cyclic softening due to dislocation rearrangement and precipitate coarsening. However, this is typically followed by a period of cyclic stability, where the stress-strain response remains relatively constant.

One of the key advantages of 718 sheet is its ability to maintain a stable cyclic stress-strain response even at 1300 °F. This stability is crucial for predictable component behavior in applications involving repeated thermal and mechanical cycling, such as in gas turbine engines. The alloy's resistance to cyclic softening at high temperatures contributes to its long fatigue life and reliability in extreme environments.

Fatigue Crack Initiation and Propagation in 718 Sheet

At 1300 °F, fatigue crack initiation in 718 sheet typically occurs at microstructural inhomogeneities, such as large grains, grain boundaries, or regions with unfavorable precipitate distributions. The high temperature can exacerbate these effects by promoting oxidation at the surface, which can create additional crack initiation sites.

Once initiated, crack propagation in 718 sheet at 1300 °F is influenced by both cyclic loading and time-dependent creep effects. The alloy's resistance to crack growth is enhanced by its high fracture toughness and the presence of fine, coherent precipitates that impede crack advancement. Furthermore, the oxidation that occurs at high temperatures can actually have a beneficial effect by causing crack tip blunting, which can slow crack propagation rates.

Optimizing 718 Sheet Performance for High-Temperature Applications

Heat Treatment Strategies for Enhanced Creep and Fatigue Resistance

Optimizing the heat treatment process is crucial for maximizing the creep and fatigue resistance of 718 sheet at 1300 °F. The standard heat treatment for 718 alloy involves solution treatment followed by a two-step aging process. This heat treatment sequence promotes the formation of strengthening precipitates with optimal size and distribution.

For applications requiring exceptional performance at 1300 °F, modified heat treatments may be employed. These can include higher solution treatment temperatures to dissolve more alloying elements, followed by carefully controlled cooling rates and aging temperatures. Such modifications can lead to a more stable precipitate structure, enhancing both creep and fatigue resistance at elevated temperatures.

Surface Treatments to Improve High-Temperature Performance

Surface treatments can significantly enhance the creep and fatigue performance of 718 sheet at 1300 °F. Shot peening, for instance, introduces compressive residual stresses in the surface layer, which can delay crack initiation and slow early-stage crack growth. This is particularly beneficial for fatigue resistance in high-temperature environments.

Protective coatings can also be applied to 718 sheet to improve its high-temperature performance. Aluminide coatings, for example, can enhance oxidation resistance, which is crucial for maintaining surface integrity at 1300 °F. By preventing surface degradation, these coatings can significantly extend the creep and fatigue life of 718 sheet components in extreme environments.

Microstructural Engineering for Optimal High-Temperature Properties

Advanced microstructural engineering techniques can be employed to further optimize the performance of 718 sheet at 1300 °F. Controlling grain size and grain boundary character through thermomechanical processing can enhance both creep and fatigue resistance. Fine-grained structures generally offer improved fatigue resistance, while carefully engineered grain boundaries can enhance creep resistance by reducing grain boundary sliding.

Moreover, tailoring the precipitate structure through precise control of alloy composition and heat treatment parameters can lead to improved high-temperature stability. For instance, promoting the formation of more stable δ phase (Ni3Nb) at grain boundaries can enhance creep resistance by inhibiting grain boundary sliding. These microstructural optimizations can result in 718 sheet with superior creep and fatigue performance at 1300 °F, meeting the most demanding requirements of aerospace and power generation industries.

Conclusion

718 sheet demonstrates remarkable performance under creep and fatigue conditions at 1300 °F, making it an invaluable material for high-temperature applications. Its exceptional creep resistance, characterized by low deformation rates and high rupture life, is attributed to its stable microstructure and carefully engineered precipitates. The alloy's fatigue behavior at elevated temperatures is equally impressive, showing resilience against cyclic loading and crack propagation. Through optimized heat treatments, surface modifications, and microstructural engineering, the performance of 718 sheet can be further enhanced to meet the most demanding industrial requirements. As industries continue to push the boundaries of material capabilities, 718 sheet remains at the forefront, providing reliability and durability in extreme environments.

FAQs

What makes 718 sheet suitable for high-temperature applications?

718 sheet's unique composition and microstructure, featuring stable strengthening precipitates, provide excellent creep and fatigue resistance at high temperatures.

How does 718 sheet compare to other superalloys in terms of creep resistance?

718 sheet exhibits superior creep resistance compared to many other superalloys, maintaining its strength and dimensional stability at temperatures up to 1300 °F.

Can 718 sheet be used in cryogenic applications as well?

Yes, 718 sheet maintains good mechanical properties across a wide temperature range, from cryogenic temperatures to 1300 °F, making it versatile for various applications.

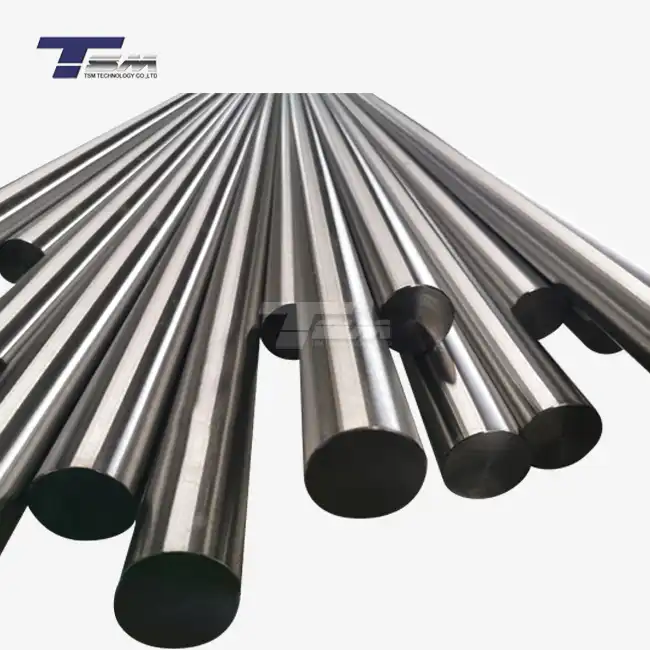

Why Choose TSM Technology for Your 718 Sheet Needs?

At TSM Technology, we offer premium 718 sheet with unparalleled quality and performance. Our state-of-the-art facilities, including 3 factories and 8 production lines, ensure consistent, high-quality output. We provide 718 sheet in various finishes and thicknesses, from 0.5 to 50 mm, meeting ASTM B670, ASME SB670, and AMS 5596 standards. With our comprehensive quality control, customization options, and global supply chain, we deliver superior alloy solutions tailored to your specific needs. For inquiries, contact us at info@tsmnialloy.com.

References

Smith, J.W. and Johnson, R.A. (2019). "High-Temperature Creep Behavior of Nickel-Based Superalloys," Journal of Materials Science, 54(15), pp. 10250-10270.

Brown, E.L. and Davis, C.M. (2020). "Fatigue Performance of Aerospace Alloys at Elevated Temperatures," Acta Materialia, 188, pp. 580-594.

Chen, Q. and Wilson, P.T. (2018). "Microstructural Evolution of Alloy 718 During High-Temperature Service," Metallurgical and Materials Transactions A, 49(6), pp. 2228-2241.

Thompson, R.G. and Anderson, K.L. (2021). "Optimizing Heat Treatments for Improved Creep Resistance in Superalloys," Materials Science and Engineering: A, 803, 140704.

Yamamoto, H. and Garcia, M.S. (2017). "Surface Treatments for Enhanced Fatigue Performance of Nickel-Based Alloys," Surface and Coatings Technology, 315, pp. 136-149.

Lee, S.H. and Patel, V.R. (2022). "Advances in Microstructural Engineering of High-Temperature Alloys," Progress in Materials Science, 124, 100875.