The Science Behind Heat Treatment of Inconel 718

Precipitation Hardening: The Core of Inconel 718's Strength

At the heart of Inconel 718's remarkable properties lies the process of precipitation hardening. This sophisticated metallurgical technique involves the formation of extremely fine particles within the alloy's microstructure. During heat treatment, specific elements in the Inconel 718 composition, such as niobium and titanium, precipitate out of the solid solution to form intermetallic compounds. These microscopic precipitates act as barriers to dislocation movement, significantly enhancing the alloy's strength and hardness.

The precipitation hardening process for Inconel 718 round bars typically involves three main stages:

- Solution Treatment: Heating the alloy to temperatures around 980°C (1800°F) to dissolve all precipitates and create a homogeneous solid solution.

- Rapid Cooling: Quickly cooling the material to room temperature to retain the supersaturated solid solution.

- Aging: Controlled heating at lower temperatures (usually around 720°C or 1330°F) to allow the formation of strengthening precipitates.

This carefully orchestrated process results in the formation of γ'' (gamma double prime) precipitates, which are primarily responsible for Inconel 718's exceptional strength. The size, distribution, and volume fraction of these precipitates are critical factors that determine the final properties of the Inconel 718 bar stock.

Microstructural Evolution During Heat Treatment

The heat treatment of Inconel 718 bars induces a complex series of microstructural changes. Initially, the alloy exists in a relatively soft, workable state with a face-centered cubic (FCC) austenitic matrix. As the heat treatment progresses, several key phases emerge:

- γ' (Gamma Prime): Ni3(Al,Ti) precipitates that contribute to strength but are less prominent in Inconel 718 compared to other superalloys.

- γ'' (Gamma Double Prime): Ni3Nb precipitates, the primary strengthening phase in Inconel 718.

- δ (Delta): An orthorhombic Ni3Nb phase that forms at grain boundaries, influencing grain size control.

The careful balance and control of these phases through precise heat treatment parameters are crucial for achieving the desired mechanical properties in Inconel 718 round bars. The formation of an optimal γ'' distribution, while minimizing detrimental δ phase formation, is a key objective of the heat treatment process.

Stress Relief and Homogenization

Beyond precipitation hardening, the heat treatment of Inconel 718 bar serves additional crucial functions. Stress relief heat treatments are often employed to alleviate internal stresses that may have developed during manufacturing processes such as forging or machining. This step is vital for ensuring dimensional stability and preventing warpage or distortion during service.

Homogenization treatments, typically conducted at high temperatures (around 1100°C or 2010°F), are sometimes necessary to eliminate chemical segregation within the Inconel 718 round bar. This process ensures a uniform distribution of alloying elements throughout the material, which is essential for consistent properties and optimal performance.

Impact of Heat Treatment on Inconel 718 Properties

Enhancement of Mechanical Strength

The most profound effect of heat treatment on Inconel 718 round bars is the dramatic increase in mechanical strength. Properly heat-treated Inconel 718 can achieve yield strengths exceeding 1000 MPa (145 ksi) and ultimate tensile strengths of up to 1400 MPa (203 ksi). This remarkable strength is maintained over a wide temperature range, making Inconel 718 bar stock an ideal choice for high-stress applications in aerospace engines, gas turbines, and nuclear reactors.

The strength enhancement is primarily attributed to the precipitation of γ'' particles, which effectively impede dislocation movement within the crystal structure. The size and distribution of these precipitates are carefully controlled through the heat treatment process to optimize strength without compromising other essential properties such as ductility.

Improved Creep and Fatigue Resistance

Heat treatment significantly enhances the creep and fatigue resistance of Inconel 718 bars. Creep, the tendency of a material to deform slowly under constant stress, is a critical concern in high-temperature applications. The precipitate structure developed during heat treatment helps to anchor dislocations and grain boundaries, effectively increasing the alloy's resistance to creep deformation.

Similarly, fatigue resistance – the ability to withstand cyclic loading – is substantially improved through proper heat treatment. The strengthened microstructure resists the initiation and propagation of fatigue cracks, leading to extended component life in dynamic loading scenarios. This property is particularly valuable in applications such as aircraft engine components and industrial gas turbines, where Inconel 718 round bars are frequently utilized.

Optimized Corrosion and Oxidation Resistance

While Inconel 718 inherently possesses excellent corrosion and oxidation resistance due to its high chromium and nickel content, heat treatment can further optimize these properties. The formation of a stable, adherent oxide layer on the surface of Inconel 718 bars during heat treatment enhances their resistance to aggressive chemical environments and high-temperature oxidation.

Moreover, the homogenization aspect of heat treatment ensures a uniform distribution of protective elements throughout the alloy matrix. This uniformity is crucial for maintaining consistent corrosion resistance across the entire cross-section of the Inconel 718 bar, preventing localized corrosion issues that could compromise the integrity of critical components.

Optimizing Heat Treatment Processes for Inconel 718 Round Bars

Precision Control of Heat Treatment Parameters

Achieving optimal properties in Inconel 718 round bars demands meticulous control over heat treatment parameters. Temperature, time, and cooling rates must be precisely managed to ensure the desired microstructure and properties are consistently achieved. Modern heat treatment facilities employ advanced temperature control systems, often utilizing multiple thermocouples and sophisticated feedback mechanisms to maintain tight temperature tolerances throughout the process.

Key parameters that require careful control include:

- Solution treatment temperature and duration

- Cooling rate from solution treatment

- Aging temperature(s) and time(s)

- Intermediate cooling rates between aging steps

Even slight deviations from the optimal heat treatment schedule can result in suboptimal properties, underscoring the importance of precision in this critical process. For instance, overaging can lead to the formation of excessive δ phase, potentially compromising the alloy's strength and ductility.

Customized Heat Treatment Cycles for Specific Applications

While standard heat treatment protocols exist for Inconel 718, the versatility of this alloy allows for customized heat treatment cycles tailored to specific application requirements. For example, components destined for ultra-high temperature service might undergo modified aging treatments to enhance long-term microstructural stability. Conversely, applications requiring maximum strength at moderate temperatures might employ different aging parameters to optimize the γ'' precipitate distribution.

Customization of heat treatment cycles for Inconel 718 round bars may involve:

- Adjusting aging temperatures and times to fine-tune precipitate size and distribution

- Implementing multi-step aging processes for enhanced property combinations

- Incorporating stress-relief treatments for components with complex geometries

- Optimizing cooling rates to balance strength and ductility requirements

This flexibility in heat treatment allows manufacturers to tailor the properties of Inconel 718 bar stock to meet the exacting demands of diverse industrial applications, from aerospace to oil and gas exploration.

Quality Assurance and Testing in Heat Treatment

Given the critical nature of heat-treated Inconel 718 components, rigorous quality assurance protocols are essential. Comprehensive testing regimes are implemented to verify that heat-treated Inconel 718 round bars meet or exceed specified property requirements. Common quality assurance measures include:

- Mechanical Testing: Tensile, yield strength, and hardness tests to confirm strength properties

- Microstructural Analysis: Metallographic examination to assess precipitate distribution and grain structure

- Non-Destructive Testing: Ultrasonic or eddy current inspections to detect any internal defects

- Chemical Analysis: To ensure composition remains within specified limits after heat treatment

Advanced techniques such as electron microscopy and X-ray diffraction may also be employed for in-depth characterization of the heat-treated microstructure. These quality assurance measures are crucial for maintaining the reliability and performance of Inconel 718 bars in critical applications where failure is not an option.

Conclusion

Heat treatment is undeniably crucial for Inconel 718 round bars, serving as the linchpin in transforming this remarkable alloy into a high-performance material capable of withstanding extreme conditions. Through carefully controlled heating and cooling cycles, heat treatment unlocks Inconel 718's full potential, dramatically enhancing its strength, creep resistance, and fatigue properties. The precision and expertise required in this process underscore its importance in the manufacturing chain. As industries continue to push the boundaries of material performance, the role of heat treatment in optimizing Inconel 718 bars remains paramount, ensuring their reliability and effectiveness in the most demanding applications across aerospace, energy, and beyond.

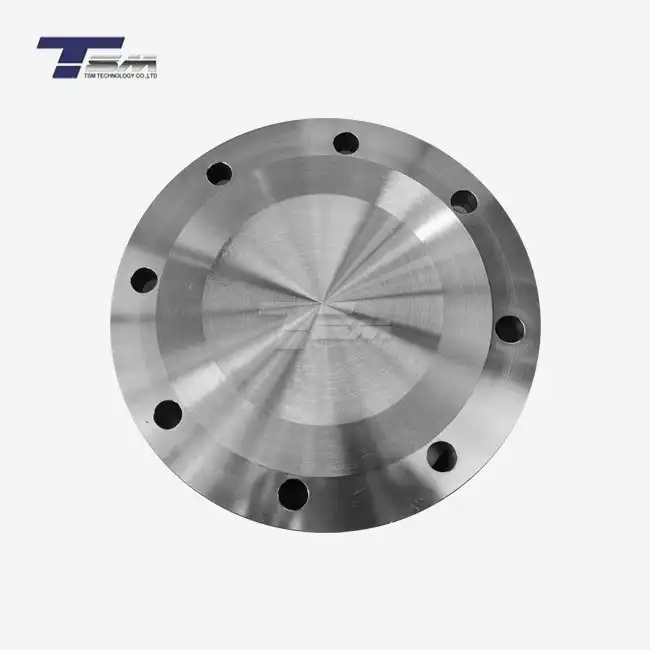

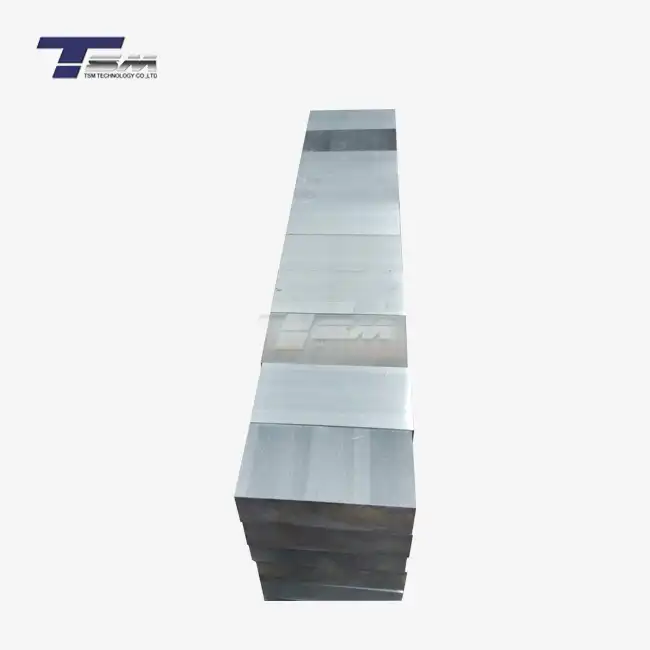

Contact Us

For more information on our premium Inconel 718 round bars and customized heat treatment services, please don't hesitate to contact TSM TECHNOLOGY. Our team of experts is ready to assist you in selecting the ideal Inconel 718 bar stock for your specific application needs. Reach out to us at info@tsmnialloy.com and discover how our superior alloy solutions can elevate your projects to new heights.