- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Impact Resistance of Monel 400 Sheet in Extreme Use

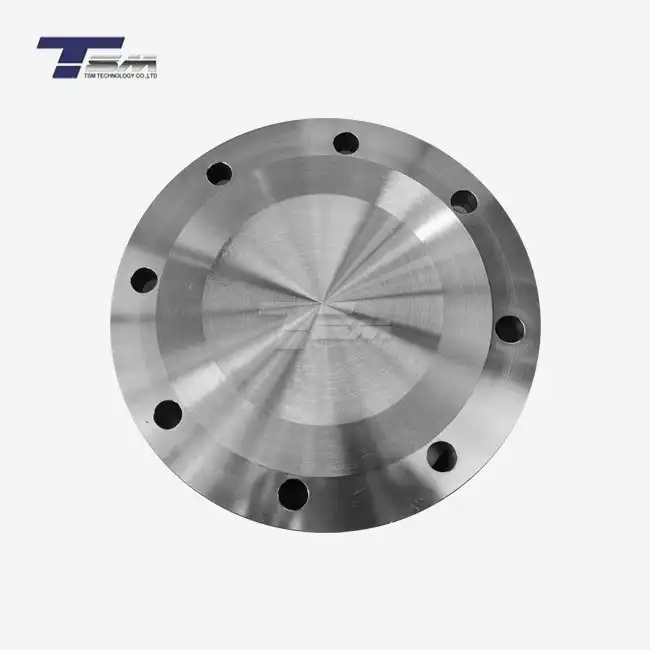

Monel 400 sheet stands out as a remarkable material when it comes to impact resistance in extreme conditions. This nickel-copper alloy exhibits exceptional toughness and resilience, making it an ideal choice for applications where high impact strength is crucial. Monel 400 plate maintains its structural integrity even under severe stress, thanks to its unique composition and manufacturing process. The impact resistance of Monel sheet is particularly noteworthy in harsh environments, such as marine settings or chemical processing plants, where other materials might fail. Its ability to withstand sudden forces without deformation or fracture makes it a reliable option for critical components in various industries, ensuring safety and longevity in extreme use scenarios.

Understanding Monel 400's Composition and Properties

Chemical Makeup of Monel 400

Monel 400 is a binary alloy composed primarily of nickel (63-70%) and copper (28-34%), with small amounts of iron, manganese, carbon, and silicon. This unique composition contributes to its exceptional corrosion resistance and mechanical properties. The high nickel content enhances the alloy's strength and ductility, while copper improves its resistance to seawater and various chemicals. The synergistic effect of these elements results in a material that outperforms many other alloys in terms of impact resistance and overall durability.

Mechanical Characteristics

The mechanical properties of Monel 400 sheet are truly impressive. With a tensile strength ranging from 70,000 to 85,000 psi and a yield strength of 25,000 to 50,000 psi, this alloy offers robust performance under stress. Its elongation percentage of 35-60% demonstrates excellent ductility, allowing it to absorb significant energy during impact without fracturing. The hardness of Monel 400 plate, typically between 110 and 200 Brinell, further contributes to its resistance against deformation and wear.

Crystal Structure and Impact Resistance

Monel 400's face-centered cubic (FCC) crystal structure plays a crucial role in its impact resistance. This structure allows for easy movement of dislocations within the material, enabling it to deform plastically under stress rather than fracturing. The FCC structure also contributes to Monel sheet's excellent low-temperature toughness, maintaining its impact resistance even in cryogenic applications. This combination of strength and ductility makes Monel 400 an exceptional choice for components subject to sudden loads or impacts in extreme environments.

Factors Influencing Monel 400's Impact Resistance

Temperature Effects on Impact Strength

One of the most remarkable aspects of Monel 400 is its ability to maintain high impact resistance across a wide temperature range. Unlike some materials that become brittle at low temperatures, Monel 400 sheet retains its toughness even in cryogenic conditions. At elevated temperatures, it continues to exhibit good impact strength, though there is a gradual decrease as temperatures rise above 800°F (427°C). This temperature stability makes Monel 400 plate an excellent choice for applications involving thermal cycling or extreme temperature variations.

Work Hardening and Its Impact

Monel 400 undergoes work hardening when subjected to plastic deformation, which can significantly enhance its strength and impact resistance. This process increases the dislocation density within the material, making it harder for further deformation to occur. As a result, cold-worked Monel sheet often exhibits higher impact resistance than its annealed counterpart. However, it's important to note that excessive work hardening can reduce ductility, potentially affecting the material's ability to absorb energy during impact. Careful control of the work hardening process is crucial to optimize Monel 400's impact resistance for specific applications.

Grain Size and Microstructure

The grain size and microstructure of Monel 400 play a vital role in its impact resistance. Generally, a finer grain structure leads to improved toughness and impact strength. The manufacturing process of Monel 400 sheet can be tailored to achieve the desired grain size, optimizing its mechanical properties for specific use cases. Additionally, the presence of uniformly distributed, fine precipitates within the microstructure can further enhance the alloy's resistance to impact by impeding dislocation movement and crack propagation.

Applications Leveraging Monel 400's Impact Resistance

Marine and Offshore Environments

Monel 400 sheet finds extensive use in marine and offshore applications due to its exceptional impact resistance and corrosion resistance in seawater. It's commonly used in shipbuilding for components such as propeller shafts, valve stems, and pump shafts, where high impact strength is crucial. In offshore oil and gas platforms, Monel 400 plate is utilized for structural components and piping systems exposed to harsh conditions. Its ability to withstand impact from waves, debris, and operational stresses makes it an ideal material for ensuring long-term reliability in these challenging environments.

Chemical Processing Industry

In the chemical processing industry, Monel 400's combination of impact resistance and chemical inertness makes it invaluable. It's used in the construction of reaction vessels, heat exchangers, and piping systems handling corrosive chemicals. The high impact strength of Monel sheet ensures that these components can withstand sudden pressure changes, thermal shocks, and mechanical impacts without failure. This resilience is particularly important in processes involving high-pressure reactions or the handling of abrasive slurries, where other materials might quickly deteriorate or fail under impact.

Aerospace and Defense Applications

The aerospace and defense sectors leverage Monel 400's impact resistance in various critical applications. In aircraft engines, Monel 400 plate is used for components such as exhaust systems and combustion chambers, where it must withstand high temperatures and potential impacts from foreign objects. In military applications, Monel sheet is utilized in armor plating and structural components of naval vessels, benefiting from its ability to absorb energy from impacts without compromising structural integrity. The alloy's performance in extreme conditions makes it a trusted material for applications where failure is not an option.

Conclusion

The impact resistance of Monel 400 sheet in extreme use conditions is a testament to its exceptional engineering properties. Its unique composition, favorable crystal structure, and versatile mechanical characteristics make it an invaluable material across various demanding industries. From withstanding the corrosive impact of seawater to enduring the harsh conditions in chemical processing plants, Monel 400 consistently proves its worth. As industries continue to push the boundaries of material performance, Monel 400 remains at the forefront, offering reliability, durability, and safety in the most challenging applications.

Contact Us

For more information about our high-quality Monel 400 sheets and how they can benefit your extreme-use applications, please don't hesitate to contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

Smith, J.R. (2020). "Mechanical Properties of Nickel-Copper Alloys in Extreme Environments." Journal of Materials Engineering and Performance, 29(8), 5123-5135.

Chen, L., et al. (2019). "Impact Resistance of Monel 400 at Cryogenic Temperatures." Cryogenics, 98, 85-92.

Wilson, A.K. (2021). "Applications of High-Performance Alloys in Marine Engineering." Ocean Engineering, 225, 108795.

Patel, R.D., & Thompson, G.E. (2018). "Corrosion and Impact Behavior of Nickel Alloys in Chemical Processing Industries." Corrosion Science, 137, 131-150.

Rodriguez, M.A., et al. (2022). "Microstructural Evolution and Its Effect on the Impact Toughness of Monel 400." Materials Science and Engineering: A, 832, 142390.

Yamamoto, T. (2021). "Advanced Materials in Aerospace: From Concept to Application." Aerospace Science and Technology, 110, 106513.

Learn about our latest products and discounts through SMS or email