The Melting and Alloying Process

Raw Material Selection and Preparation

The production of Hastelloy C276 tubes starts with the careful selection of high-purity raw materials. These typically include nickel, molybdenum, chromium, iron, and small amounts of other elements like tungsten and manganese. The precise composition is crucial for achieving the alloy's superior corrosion resistance and mechanical properties.

Before melting, the raw materials undergo thorough cleaning and preparation to remove any contaminants that could compromise the final product's quality. This may involve acid washing, degreasing, and drying processes to ensure the highest level of purity.

Vacuum Induction Melting (VIM)

The primary melting process for Hastelloy C276 is typically Vacuum Induction Melting (VIM). This advanced technique allows for precise control over the alloy composition and minimizes the risk of unwanted impurities. In a VIM furnace, the raw materials are melted under a vacuum, which prevents oxidation and helps maintain the desired chemical balance.

During the melting process, the furnace operators carefully monitor and adjust the temperature and power input to ensure complete melting and homogenization of the alloy components. The molten metal is then carefully poured into molds to form ingots or billets, which will serve as the starting point for further processing of the Hastelloy C276 tube.

Secondary Refining Techniques

To further enhance the purity and properties of the Hastelloy C276 alloy, secondary refining techniques may be employed. These can include Electroslag Remelting (ESR) or Vacuum Arc Remelting (VAR). These processes help to remove residual gases, reduce segregation, and improve the overall microstructure of the alloy.

In ESR, the ingot is gradually remelted using electrical current passed through a layer of reactive slag. This process helps to remove impurities and refine the grain structure. VAR, on the other hand, involves remelting the ingot in a vacuum chamber using an electric arc, which further purifies the alloy and enhances its mechanical properties.

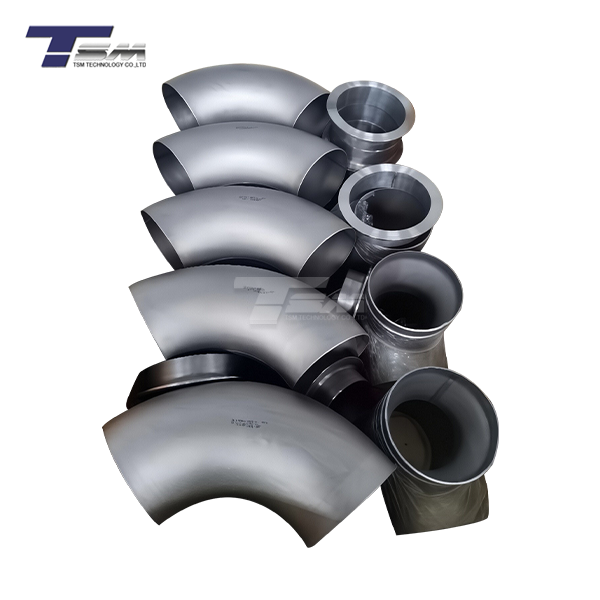

Forming and Shaping Hastelloy C276 Tubes

Hot Working and Extrusion

Once the Hastelloy C276 ingots have solidified and cooled, they undergo hot working processes to break down the as-cast structure and improve the material's properties. Hot working typically occurs at temperatures above the recrystallization point of the alloy, allowing for easier deformation and shaping.

For Hastelloy C276 seamless pipe production, the ingots are often first forged into billets or round bars. These are then heated to temperatures typically ranging from 1150°C to 1260°C (2100°F to 2300°F) before being extruded through a die to create the initial tube shape. The extrusion process helps to refine the grain structure and improve the alloy's overall strength and ductility.

Cold Drawing and Sizing

After hot working, the Hastelloy C276 tubes undergo cold drawing to achieve the final dimensions and improve surface finish. Cold drawing involves pulling the tube through a series of dies with progressively smaller diameters. This process not only reduces the tube's diameter and wall thickness but also work-hardens the material, enhancing its strength and hardness.

Multiple passes of cold drawing may be required to reach the desired specifications for the Hastelloy C276 tubing. Between drawing passes, the tubes may undergo intermediate annealing treatments to restore ductility and prevent excessive work hardening.

Heat Treatment and Stress Relief

To optimize the mechanical properties and corrosion resistance of Hastelloy C276 tubes, appropriate heat treatment is essential. Solution annealing is a common heat treatment process used for this alloy. It typically involves heating the tubes to temperatures between 1120°C and 1180°C (2050°F and 2160°F), followed by rapid cooling, usually by water quenching.

This heat treatment process dissolves any precipitates that may have formed during the manufacturing process, ensuring a homogeneous microstructure and maximizing the alloy's corrosion resistance. Additionally, stress relief treatments may be performed to reduce any residual stresses from the forming and drawing processes, enhancing the dimensional stability of the Hastelloy C276 seamless pipes.

Final Processing and Quality Assurance

Surface Finishing and Treatment

The final stages of Hastelloy C276 tube production involve various surface finishing processes to achieve the desired appearance and performance characteristics. Common surface treatments include:

- Pickling: This chemical process removes surface oxides and contaminants, leaving a clean, passive surface that enhances corrosion resistance.

- Mechanical polishing: Abrasive techniques are used to smooth the surface, reducing roughness and improving the tube's aesthetic appeal.

- Electropolishing: An electrochemical process that further enhances surface smoothness and corrosion resistance by selectively removing material at a microscopic level.

The choice of surface finish depends on the specific application requirements for the Hastelloy C276 tubing. Some applications may require a mirror-like finish for hygienic purposes, while others may prioritize a specific surface roughness for optimal fluid flow characteristics.

Non-Destructive Testing and Inspection

Quality assurance is paramount in the production of Hastelloy C276 tubes. Various non-destructive testing (NDT) methods are employed to ensure the integrity and conformity of the final product. These may include:

- Ultrasonic testing: To detect internal defects and ensure wall thickness uniformity.

- Eddy current testing: For identifying surface and near-surface flaws.

- Hydrostatic pressure testing: To verify the tube's ability to withstand specified pressures without leakage.

- Dimensional checks: To confirm compliance with size and tolerance specifications.

Additionally, metallurgical examinations and chemical composition analyses are conducted to verify that the Hastelloy C276 seamless pipes meet the required material specifications and performance criteria.

Packaging and Documentation

The final step in the production process involves proper packaging of the Hastelloy C276 tubes to protect them during transportation and storage. This may include applying protective coatings, capping tube ends, and using appropriate packaging materials to prevent damage or contamination.

Comprehensive documentation is prepared, including material test reports, certification of compliance, and any specific documentation required by the customer or industry standards. This documentation ensures traceability and assures the product's quality and conformity to specifications.

Conclusion

The manufacturing of Hastelloy C276 tubes is a complex process that combines advanced metallurgical techniques with precision engineering. From the initial melting of raw materials to the final surface finishing and quality assurance steps, each stage is carefully controlled to produce high-quality Hastelloy C276 seamless pipes and tubing. This meticulous approach ensures that the resulting products possess the exceptional corrosion resistance, strength, and reliability required for critical applications in challenging environments. As technology advances, manufacturers continue to refine these processes, pushing the boundaries of what's possible with this remarkable alloy.

Contact Us

For more information about our high-quality Hastelloy C276 tubes and other superior alloy products, please don't hesitate to contact TSM TECHNOLOGY. Our team of experts is ready to assist you in finding the perfect solution for your engineering needs. Contact us at: info@tsmnialloy.com