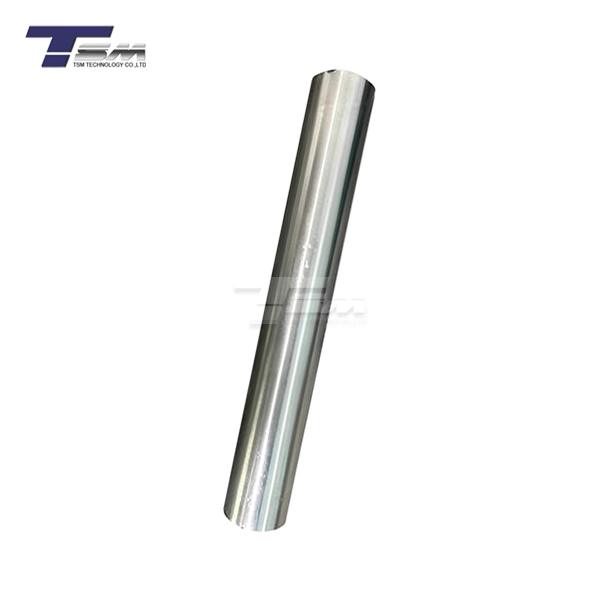

Understanding Hastelloy C276 Material Properties

Chemical Composition and Microstructure

Hastelloy C276 is a nickel-molybdenum-chromium alloy renowned for its exceptional corrosion resistance and mechanical strength. The unique chemical composition of this superalloy, typically consisting of 57% nickel, 16% molybdenum, and 16% chromium, along with smaller amounts of tungsten and other elements, contributes to its outstanding performance in aggressive environments. The microstructure of Hastelloy C276 tubes is characterized by a solid solution-strengthened austenitic matrix, which imparts excellent stability and resistance to various forms of corrosion.

Mechanical Characteristics

Hastelloy C276 tubing exhibits remarkable mechanical properties, including high tensile strength, excellent ductility, and superior resistance to stress corrosion cracking. These characteristics make it an ideal material for applications involving extreme temperatures and pressures, as well as exposure to corrosive chemicals. The alloy's ability to maintain its properties over a wide range of temperatures further enhances its versatility in industrial settings.

Corrosion Resistance Profile

One of the most notable features of Hastelloy C276 seamless pipes is their exceptional resistance to a broad spectrum of corrosive media. This alloy demonstrates superior performance in oxidizing and reducing environments, including resistance to pitting, crevice corrosion, and stress corrosion cracking. Its ability to withstand attack from chloride-containing solutions, mineral acids, and organic compounds makes it invaluable in chemical processing and marine applications.

Key Mechanical Tests for Hastelloy C276 Tubes

Tensile Strength Testing

Tensile strength testing is a fundamental mechanical evaluation performed on Hastelloy C276 tubes to assess their ability to withstand longitudinal stress. This test involves applying a gradually increasing load to a specimen until failure occurs. Key parameters measured during tensile testing include yield strength, ultimate tensile strength, and elongation. For Hastelloy C276 tubing, typical tensile strength values range from 100,000 to 120,000 psi (690 to 827 MPa), with a minimum elongation of 40%. These tests ensure that the material meets specified strength requirements for its intended applications.

Hardness Evaluation

Hardness testing is another critical assessment for Hastelloy C276 seamless pipes. This test measures the material's resistance to localized plastic deformation induced by mechanical indentation or abrasion. Common hardness testing methods for Hastelloy C276 tube include Rockwell B and Brinell tests. Typical hardness values for Hastelloy C276 range from 85 to 95 on the Rockwell B scale. Hardness evaluations provide valuable insights into the material's wear resistance and can indicate its overall strength and durability in service conditions.

Corrosion Resistance Testing

Given the primary application of Hastelloy C276 in corrosive environments, comprehensive corrosion resistance testing is paramount. These tests may include immersion tests in various acidic and alkaline solutions, as well as electrochemical tests to evaluate pitting and crevice corrosion resistance. Specific corrosion tests for Hastelloy C276 tubes often include exposure to boiling hydrochloric acid, ferric chloride solutions, and simulated seawater environments. The results of these tests validate the material's suitability for use in aggressive chemical processing and marine applications.

Advanced Mechanical Testing Techniques

Fatigue Testing

Fatigue testing is crucial for assessing the long-term performance of Hastelloy C276 tubing under cyclic loading conditions. This test involves subjecting specimens to repeated stress cycles to determine the material's fatigue strength and endurance limit. For Hastelloy C276 seamless pipes, fatigue testing typically involves both low-cycle and high-cycle fatigue evaluations. The results of these tests are essential for predicting the service life of components in applications involving dynamic loads, such as in heat exchangers or pressure vessels.

Creep Testing

Creep testing is particularly relevant for Hastelloy C276 tubes intended for high-temperature applications. This test evaluates the material's resistance to time-dependent deformation under constant load and elevated temperatures. Creep testing for Hastelloy C276 typically involves exposing specimens to temperatures ranging from 600°C to 1000°C under various stress levels. The data obtained from creep tests are critical for designing components that must maintain dimensional stability and mechanical integrity over extended periods at high temperatures.

Impact Toughness Evaluation

Impact toughness testing assesses the ability of Hastelloy C276 seamless pipes to resist fracture under sudden, high-strain rate loading conditions. The Charpy V-notch test is commonly used to evaluate impact toughness, providing valuable information about the material's ductile-to-brittle transition behavior. For Hastelloy C276, impact toughness testing is often conducted at various temperatures to ensure adequate performance across the full range of operating conditions. This test is particularly important for applications where sudden impacts or thermal shocks may occur.

Conclusion

Comprehensive mechanical testing of Hastelloy C276 tubes is essential for ensuring their reliability and performance in demanding industrial applications. From basic tensile and hardness tests to advanced fatigue and creep evaluations, these assessments provide critical data for material selection, component design, and quality assurance. By adhering to rigorous testing protocols, manufacturers and end-users can confidently deploy Hastelloy C276 seamless pipes and tubing in the most challenging environments, leveraging their exceptional corrosion resistance and mechanical properties to enhance operational efficiency and safety across various industries.

Contact Us

For expert guidance on Hastelloy C276 tube selection and testing, contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of specialists is ready to assist you in choosing the right Hastelloy C276 products for your specific application needs.