Understanding the Corrosion Resistance of Inconel 625 Flanges

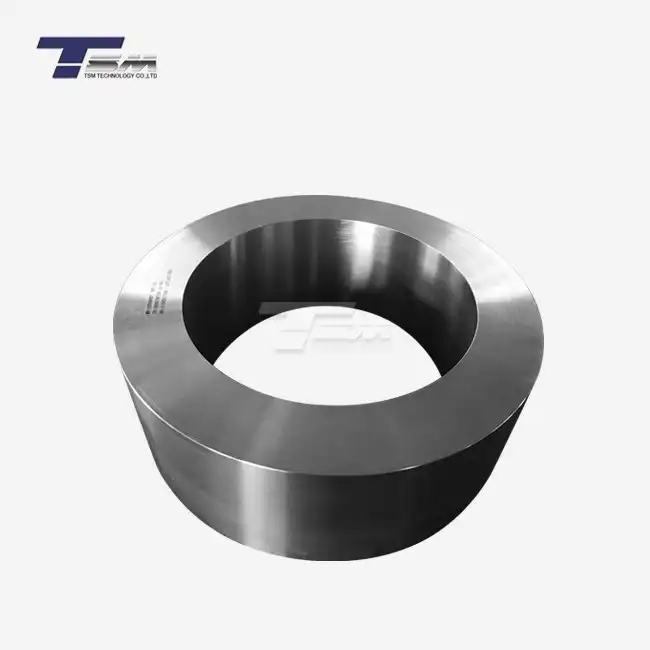

Composition and Microstructure

Inconel 625 flanges owe their remarkable corrosion resistance to their carefully engineered composition. The alloy typically contains 58% nickel, 20-23% chromium, 8-10% molybdenum, and smaller amounts of niobium and iron. This unique blend creates a face-centered cubic austenitic structure that contributes to the material's exceptional stability in corrosive environments. The high nickel content provides resistance to reducing conditions, while chromium forms a protective oxide layer that regenerates when damaged, offering continuous protection against oxidizing media.

Passive Film Formation

One of the key mechanisms behind the corrosion resistance of Inconel 625 flanges is the formation of a passive film on their surface. When exposed to oxygen or other oxidizing agents, the chromium in the alloy reacts to form a thin, adherent chromium oxide layer. This passive film acts as a barrier, preventing further corrosion by limiting the direct contact between the base metal and the corrosive environment. The presence of molybdenum in the alloy enhances the stability of this passive layer, particularly in environments containing chlorides, which are notorious for causing pitting corrosion in many other materials.

Resistance to Specific Corrosive Media

Alloy 625 flanges exhibit exceptional resistance to a wide range of corrosive media commonly encountered in chemical plants. They perform admirably in sulfuric, hydrochloric, and nitric acids, even at elevated temperatures. The material also shows excellent resistance to caustic alkali solutions, making it suitable for processes involving sodium hydroxide or potassium hydroxide. In chloride-containing environments, which are particularly challenging for many materials, Inconel 625 flanges demonstrate superior resistance to stress corrosion cracking and pitting corrosion, outperforming many other alloys in these aggressive conditions.

Applications of Inconel 625 Flanges in Chemical Processing

Acid Production and Handling

In chemical plants dedicated to acid production, Inconel 625 flanges play a crucial role in maintaining system integrity. These components are extensively used in sulfuric acid plants, where they withstand the corrosive nature of both the acid and sulfur dioxide gas. In hydrochloric acid production facilities, alloy 625 flanges are employed in heat exchangers, reactors, and transfer lines, where their resistance to both the acid and chlorine gas is paramount. The flanges' ability to maintain their properties at elevated temperatures makes them ideal for processes involving hot acid streams or vapor phases.

Petrochemical Processing

The petrochemical industry relies heavily on Inconel 625 flanges for various critical applications. In processes involving naphtha crackers, these flanges are used in high-temperature sections where resistance to both corrosion and creep is essential. Alloy 625 flanges are also found in catalytic reforming units, where they withstand the combined effects of high temperatures and corrosive environments containing hydrogen sulfide and chlorides. Their excellent performance in these demanding conditions contributes to increased plant reliability and reduced maintenance costs.

Chlor-alkali Production

The chlor-alkali industry, which produces chlorine, sodium hydroxide, and hydrogen through the electrolysis of brine, heavily relies on corrosion-resistant materials like Inconel 625. Flanges made from this alloy are used in various parts of the process, including chlorine drying and compression systems, where they resist both wet and dry chlorine. In caustic evaporation units, these flanges withstand highly concentrated sodium hydroxide solutions at elevated temperatures, demonstrating their versatility in handling both acidic and alkaline environments.

Factors Affecting Corrosion Performance of Inconel 625 Flanges

Temperature Effects

Temperature plays a significant role in the corrosion behavior of Inconel 625 flanges. While the alloy maintains excellent corrosion resistance across a wide temperature range, extreme temperatures can influence its performance. At very high temperatures (above 1000°C), the protective chromium oxide layer may become unstable, potentially leading to accelerated oxidation. Conversely, at cryogenic temperatures, the material retains its toughness and corrosion resistance, making it suitable for applications involving liquefied gases. Understanding these temperature-dependent behaviors is crucial for optimizing the use of alloy 625 flanges in various chemical plant processes.

Stress and Fatigue Considerations

While Inconel 625 flanges boast impressive corrosion resistance, the combination of stress and corrosive environments can potentially lead to stress corrosion cracking (SCC) under certain conditions. However, the alloy's high nickel content provides significant protection against SCC compared to many other materials. Proper design and installation of flanges, ensuring even load distribution and minimizing residual stresses, can further enhance their resistance to SCC. Additionally, the material's excellent fatigue strength contributes to its longevity in applications involving cyclic loading, such as in pumps and compressors handling corrosive fluids.

Surface Condition and Welding Effects

The surface condition of Inconel 625 flanges can significantly impact their corrosion performance. Smooth, properly finished surfaces promote the formation of a more uniform and effective passive layer, enhancing corrosion resistance. Welding, while generally straightforward with this alloy, can potentially alter the local microstructure and composition. Proper welding procedures, including appropriate filler materials and post-weld heat treatments, are essential to maintain the corrosion resistance of welded joints in Inconel 625 flange assemblies. Regular inspection and maintenance of flange surfaces and welds can help ensure optimal corrosion performance throughout the service life of the equipment.

Conclusion

Inconel 625 flanges stand out as exceptional components for corrosion resistance in chemical plant applications. Their unique composition and microstructure provide superior protection against a wide array of corrosive media, from acids to alkalis and chlorides. The ability to form a stable passive film, coupled with excellent mechanical properties, makes these alloy 625 flanges indispensable in critical processes within the chemical industry. By understanding the factors affecting their performance and implementing proper design and maintenance practices, engineers can leverage the full potential of Inconel 625 flanges to enhance plant reliability, safety, and efficiency in corrosive environments.

FAQs

What makes Inconel 625 flanges superior for chemical plant applications?

Inconel 625 flanges offer exceptional corrosion resistance, high-temperature strength, and durability in aggressive chemical environments. Their unique composition, including nickel, chromium, and molybdenum, protects a wide range of corrosive media.

Can Inconel 625 flanges withstand both acidic and alkaline environments?

Yes, Inconel 625 flanges demonstrate excellent resistance to both acidic and alkaline conditions, making them versatile for various chemical processing applications.

How does temperature affect the performance of Inconel 625 flanges?

While Inconel 625 flanges maintain good corrosion resistance across a wide temperature range, extreme temperatures can impact their performance. They perform exceptionally well at high temperatures but may require special considerations in very high-temperature applications (above 1000°C).

Corrosion Performance of Inconel 625 Flange in Chemical Plants | TSM TECHNOLOGY

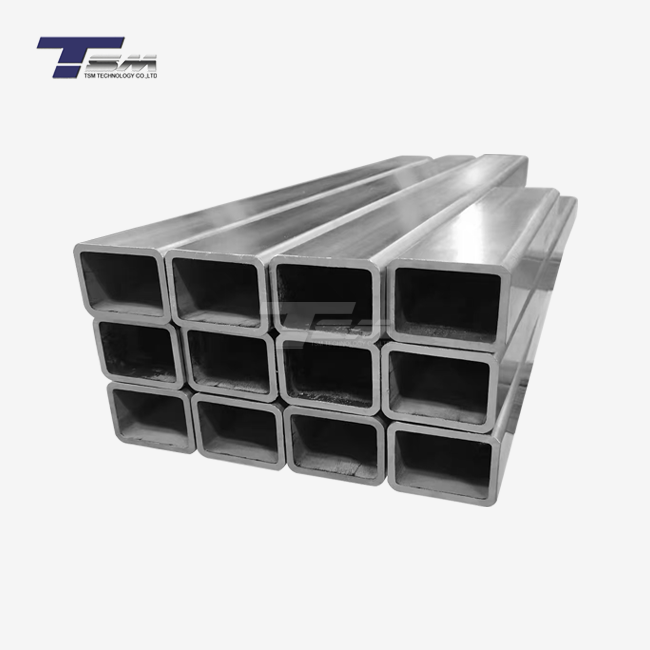

At TSM Technology, we specialize in manufacturing high-quality Inconel 625 flanges for chemical plant applications. Our state-of-the-art facilities, equipped with 100+ machines across 3 factories and 8 production lines, ensure superior corrosion performance and reliability. With a monthly supply capacity of 300 tons and adherence to ASTM B564 / ASME SB564 standards, we offer customized solutions to meet your specific needs. For expert guidance on Inconel 625 flanges for your chemical plant, contact us at info@tsmnialloy.com.

References

Special Metals Corporation. (2013). Inconel alloy 625 Technical Data Sheet.

Klarstrom, D. L., Crook, P., & Wu, J. B. (2002). Metallurgical factors affecting the corrosion resistance of nickel-base alloys. Corrosion, 58(1), 30-37.

Rebak, R. B., & Crook, P. (2000). Nickel alloys for corrosive environments. Advanced Materials & Processes, 158(6), 37-42.

Davis, J. R. (Ed.). (2000). Nickel, cobalt, and their alloys. ASM International.

Nishimura, R. (2007). Pitting corrosion of nickel-based alloys in chloride and sulfate solutions. Corrosion, 63(6), 534-542.

Tawancy, H. M., Ul-Hamid, A., & Abbas, N. M. (2004). Practical Engineering Failure Analysis. CRC Press.