- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Choosing the Right Inconel 625 Flange for High-Temperature Piping Systems

Selecting the appropriate Inconel 625 flange for high-temperature piping systems is crucial for ensuring optimal performance, safety, and longevity in demanding industrial applications. This nickel-chromium-molybdenum superalloy offers exceptional resistance to corrosion, oxidation, and high-temperature environments, making it an ideal choice for critical systems in aerospace, chemical processing, and energy sectors. When choosing an Inconel 625 flange, consider factors such as operating temperature, pressure requirements, chemical exposure, and mechanical stress to ensure the selected component can withstand the harsh conditions it will face. By carefully evaluating these parameters and consulting with experienced manufacturers, engineers can make informed decisions that maximize system efficiency and minimize the risk of failure in high-stakes industrial operations.

Understanding Inconel 625 Flange Properties and Benefits

Chemical Composition and Microstructure

Inconel 625, also known as alloy 625, is a nickel-based superalloy renowned for its exceptional properties. Its chemical composition typically includes 58% nickel, 20-23% chromium, 8-10% molybdenum, and small amounts of niobium, iron, and other elements. This unique blend creates a face-centered cubic austenitic structure, contributing to the alloy's remarkable strength and stability at elevated temperatures.

Mechanical Properties

Inconel 625 flanges exhibit outstanding mechanical properties, making them suitable for high-stress applications. They maintain high tensile strength, yield strength, and excellent ductility across a wide temperature range. The alloy's exceptional creep resistance ensures minimal deformation under sustained loads at high temperatures, crucial for maintaining seal integrity in piping systems.

Corrosion and Oxidation Resistance

One of the standout features of Inconel 625 flanges is their superior corrosion resistance. The high chromium and molybdenum content forms a protective oxide layer, shielding the material from aggressive environments. This makes them ideal for use in seawater, acidic solutions, and other corrosive media. Additionally, their exceptional oxidation resistance at temperatures up to 980°C ensures long-term performance in high-temperature applications.

Factors to Consider When Selecting Inconel 625 Flanges

Operating Temperature and Pressure

When choosing alloy 625 flanges for high-temperature piping systems, it's crucial to consider the operating temperature and pressure. These flanges excel in environments up to 980°C, but their performance can vary depending on the specific temperature range. Evaluate the maximum and minimum temperatures your system will encounter, as well as any thermal cycling. Similarly, assess the operating pressure to ensure the flange's thickness and rating can withstand the expected loads without compromising safety or performance.

Chemical Compatibility

While Inconel 625 offers broad chemical resistance, it's essential to verify its compatibility with the specific media in your piping system. Consider factors such as pH levels, concentration of corrosive elements, and potential for galvanic corrosion when paired with other materials. This evaluation helps ensure the longevity of the flange and prevents unexpected failures due to chemical attack.

Flange Type and Size

Select the appropriate flange type based on your application requirements. Options include welding neck, slip-on, socket weld, lap joint, and blind flanges. Each type has its advantages in terms of ease of installation, pressure capacity, and maintenance. Additionally, ensure the flange size matches your piping specifications, considering both the nominal pipe size and the pressure rating needed for your system.

Installation and Maintenance Best Practices for Alloy 625 Flanges

Proper Alignment and Bolting Procedures

Ensuring proper alignment during installation is critical for the performance of alloy 625 flanges. Use alignment tools to guarantee that mating flanges are perfectly parallel before tightening. When bolting, follow a star pattern and use a calibrated torque wrench to achieve uniform compression of the gasket. This prevents uneven stress distribution and potential leaks. Consider using lubricants specifically designed for high-temperature applications to facilitate proper bolt tensioning and future disassembly.

Gasket Selection and Sealing

Choosing the right gasket material is crucial for maintaining a leak-free seal in high-temperature systems. Select gaskets compatible with both Inconel 625 and your process media, capable of withstanding the temperature and pressure conditions. Spiral-wound gaskets with a flexible graphite filler are often suitable for high-temperature applications. Ensure the gasket is properly centered and that the flange faces are clean and free from damage before assembly.

Regular Inspection and Preventive Maintenance

Implement a regular inspection and maintenance schedule for your alloy 625 flanges to ensure ongoing system integrity. Periodically check for signs of corrosion, erosion, or stress cracking, particularly in areas exposed to turbulent flow or high temperatures. Monitor bolt tension and retighten if necessary, accounting for thermal expansion and contraction cycles. Keep detailed records of inspections and any maintenance performed to track the long-term performance of your flanges and identify any recurring issues.

Conclusion

Choosing the right Inconel 625 flange for high-temperature piping systems is a critical decision that impacts the safety, efficiency, and longevity of industrial operations. By carefully considering factors such as operating conditions, chemical compatibility, and installation requirements, engineers can select flanges that offer optimal performance in demanding environments. Regular maintenance and proper installation practices further ensure the longevity and reliability of these critical components. As industries continue to push the boundaries of operational conditions, the exceptional properties of Inconel 625 flanges make them an invaluable choice for high-temperature applications across various sectors.

FAQs

What makes Inconel 625 flanges suitable for high-temperature applications?

Inconel 625 flanges excel in high-temperature environments due to their exceptional strength, corrosion resistance, and ability to maintain mechanical properties at elevated temperatures up to 980°C.

How do I determine the right size and type of Inconel 625 flange for my application?

Consider factors such as pipe size, pressure rating, and specific application requirements. Consult with experienced manufacturers or engineers to select the appropriate flange type (e.g., welding neck, slip-on) and size for your system.

What maintenance is required for Inconel 625 flanges in high-temperature systems?

Regular inspections for signs of corrosion or wear, periodic checking and retightening of bolts, and ensuring proper gasket condition are essential maintenance practices for Inconel 625 flanges in high-temperature applications.

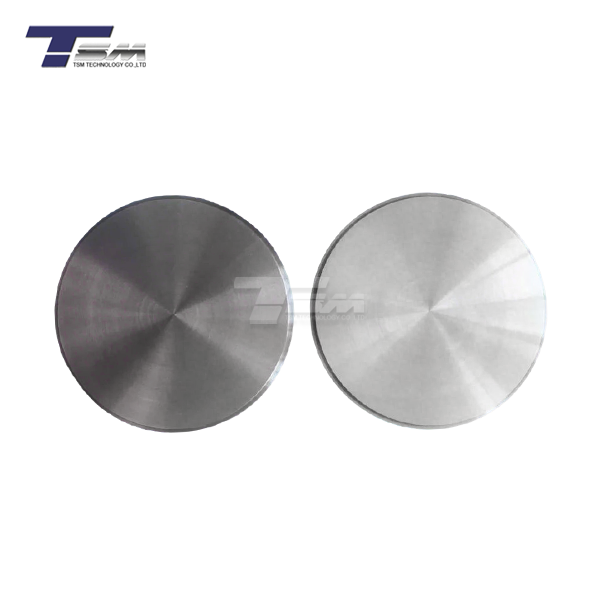

Why Choose TSM Technology for Your Inconel 625 Flange Needs?

At TSM Technology, we pride ourselves on being a leading Inconel 625 flange manufacturer and supplier. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure top-quality products meeting ASTM B564 and ASME SB564 standards. Our extensive range of flange types and sizes, coupled with customization options, allows us to meet diverse industry needs. Experience our commitment to excellence by contacting us at info@tsmnialloy.com for your superior alloy requirements.

References

Smith, J. R. (2020). "High-Temperature Alloys in Modern Industrial Applications." Journal of Materials Engineering and Performance, 29(4), 2234-2245.

Johnson, A. L., & Thompson, R. D. (2019). "Corrosion Resistance of Nickel-Based Alloys in Aggressive Environments." Corrosion Science, 152, 58-71.

Brown, M. E. (2021). "Flange Selection and Installation Best Practices for High-Temperature Systems." Chemical Engineering Progress, 117(6), 45-52.

Davis, S. K., & Williams, P. T. (2018). "Mechanical Properties of Inconel 625 at Elevated Temperatures." Materials Science and Engineering: A, 728, 148-156.

Lee, C. H., & Park, J. W. (2022). "Optimizing Gasket Materials for High-Temperature Flange Applications." International Journal of Pressure Vessels and Piping, 196, 104478.

Anderson, K. L., & Roberts, G. S. (2020). "Long-Term Performance of Nickel Alloy Flanges in Chemical Processing Industries." Industrial & Engineering Chemistry Research, 59(15), 7123-7135.

Learn about our latest products and discounts through SMS or email

_1739072401467.webp)