- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Corrosion Resistance of Inconel 601 Sheet in Chemical Processing

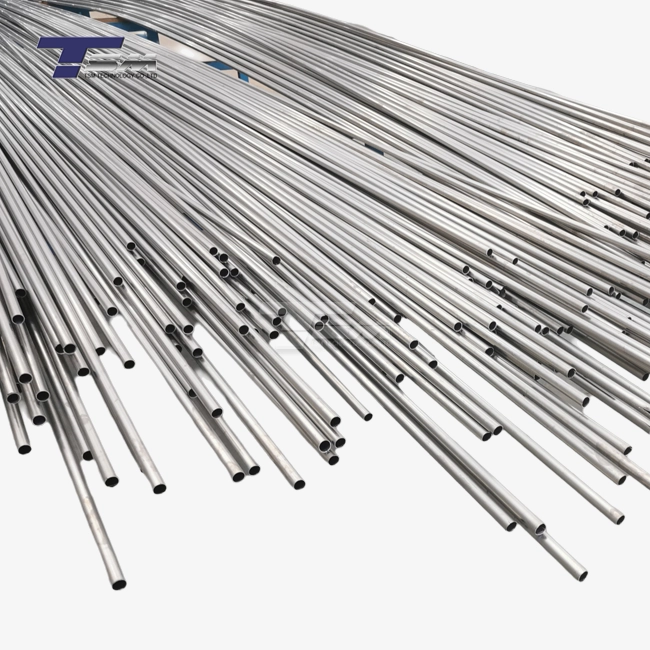

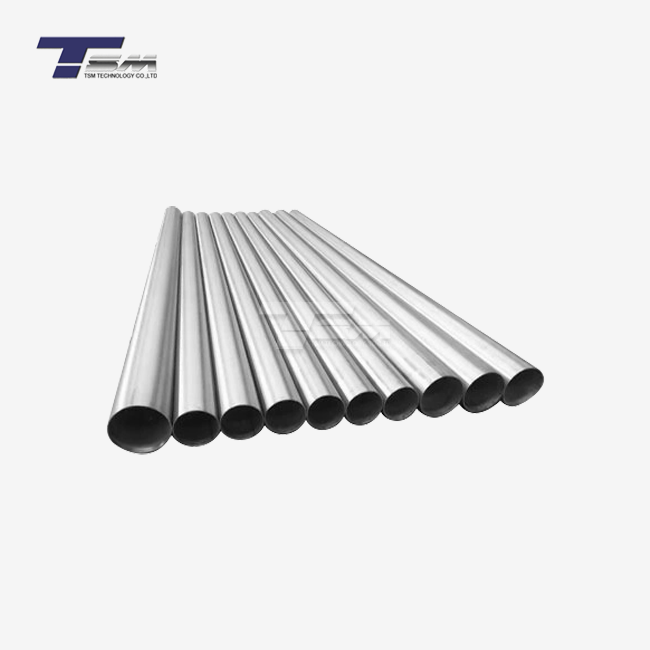

Inconel 601 sheet is a high-performance nickel-chromium-aluminum alloy that exhibits exceptional corrosion resistance in chemical processing environments. Its unique composition, featuring approximately 60% nickel, 23% chromium, and 1.4% aluminum, creates a protective oxide layer that shields the material from aggressive chemical attacks. This remarkable corrosion resistance makes Inconel 601 plate an ideal choice for equipment and components in various chemical processing applications, including reactors, heat exchangers, and piping systems. The alloy's ability to withstand harsh conditions, high temperatures, and corrosive media ensures extended service life and improved operational efficiency in chemical processing facilities.

Chemical Composition and Microstructure of Inconel 601

Elemental Breakdown

Inconel 601 sheet's chemical composition plays a crucial role in its corrosion resistance. The alloy typically contains: Nickel: 58.0-63.0%, Chromium: 21.0-25.0%, Iron: 6.0-10.0%, Aluminum: 1.0-1.7%, Carbon: 0.10% max, Silicon: 0.50% max, Manganese: 1.0% max, Copper: 1.0% max, Sulfur: 0.015% max. This carefully balanced composition contributes to the formation of a stable, adherent oxide layer that protects the underlying metal from corrosive attack.

Microstructural Features

The microstructure of Inconel 601 plate consists of a face-centered cubic austenitic matrix with dispersed precipitates. This structure is achieved through a combination of solution annealing and controlled cooling. The presence of chromium and aluminum in the alloy promotes the formation of a protective oxide scale, primarily composed of Cr2O3 and Al2O3, which enhances the material's corrosion resistance in various chemical environments.

Heat Treatment Effects

Heat treatment processes significantly influence the microstructure and, consequently, the corrosion resistance of Inconel 601 sheet. Solution annealing at temperatures between 1050°C and 1200°C followed by rapid cooling, helps to homogenize the microstructure and optimize the distribution of alloying elements. This treatment enhances the material's ability to form a uniform protective oxide layer, further improving its corrosion resistance in chemical processing applications.

Corrosion Mechanisms and Resistance in Chemical Environments

Oxidation Resistance

Inconel 601 plate exhibits exceptional oxidation resistance in high-temperature environments, making it suitable for use in chemical processing equipment operating at elevated temperatures. The alloy's ability to form a stable Cr2O3 and Al2O3 scale protects it from rapid oxidation, even in aggressive oxidizing atmospheres. This property is particularly valuable in applications involving hot corrosive gases or oxidizing chemical vapors.

Resistance to Acids and Alkalis

Inconel 601 sheet demonstrates remarkable resistance to a wide range of acids and alkalis commonly encountered in chemical processing. It performs well in sulfuric acid environments up to moderate concentrations and temperatures. The alloy also shows good resistance to hydrochloric acid, phosphoric acid, and various organic acids. In alkaline solutions, Inconel 601 maintains its integrity, making it suitable for use in caustic processing equipment.

Stress Corrosion Cracking (SCC) Resistance

Stress corrosion cracking is a significant concern in chemical processing environments. Inconel 601 plate exhibits good resistance to SCC in chloride-containing media, which is often a challenge for many other alloys. This resistance is attributed to the high nickel content and the presence of chromium, which helps prevent crack initiation and propagation under stress in corrosive environments.

Applications and Performance in Chemical Processing Industries

Petrochemical Industry

In petrochemical plants, Inconel 601 sheet finds extensive use in various critical components. It is employed in the construction of reactor vessels, heat exchangers, and piping systems that handle corrosive chemicals at high temperatures. The alloy's ability to withstand sulfidation attack makes it particularly valuable in processes involving sulfur-containing compounds, such as in desulfurization units and catalytic cracking operations.

Pharmaceutical Manufacturing

The pharmaceutical industry relies on Inconel 601 plate for equipment that requires high purity and corrosion resistance. It is used in the fabrication of reaction vessels, storage tanks, and transfer lines for various pharmaceutical processes. The alloy's resistance to a wide range of organic and inorganic compounds ensures product integrity and minimizes the risk of contamination during drug manufacturing.

Chemical Processing Equipment

Inconel 601 sheet is widely used in the production of chemical processing equipment such as distillation columns, evaporators, and agitators. Its excellent corrosion resistance in both oxidizing and reducing environments makes it an ideal choice for handling a diverse range of chemicals. The alloy's high strength at elevated temperatures also contributes to the longevity and reliability of equipment in demanding chemical processing operations.

Conclusion

Inconel 601 sheet stands out as a superior material for corrosion resistance in chemical processing applications. Its unique composition and microstructure provide exceptional protection against a wide range of corrosive environments, from high-temperature oxidation to acid and alkali attack. The alloy's versatility and durability make it an invaluable asset in the petrochemical, pharmaceutical, and general chemical processing industries. As chemical processes continue to evolve and become more demanding, Inconel 601 plate remains a reliable choice for ensuring equipment longevity, operational efficiency, and safety in corrosive environments.

FAQs

What makes Inconel 601 sheet resistant to corrosion in chemical processing?

The alloy's high nickel and chromium content forms a protective oxide layer, shielding it from corrosive attacks.

Can Inconel 601 plate withstand high temperatures in chemical environments?

Yes, it maintains excellent corrosion resistance at temperatures up to 1200°C.

Is Inconel 601 sheet suitable for use in sulfuric acid environments?

It performs well in moderate concentrations of sulfuric acid at various temperatures.

How does Inconel 601 compare to other alloys in terms of stress corrosion cracking resistance?

Inconel 601 exhibits superior resistance to stress corrosion cracking, especially in chloride-containing environments.

What are the key industries that benefit from Inconel 601's corrosion resistance?

Petrochemical, pharmaceutical, and general chemical processing industries greatly benefit from its properties.

Choose TSM TECHNOLOGY for Your Inconel 601 Sheet Needs

At TSM TECHNOLOGY, we are your premier Inconel 601 sheet manufacturer and supplier. Our state-of-the-art facilities and stringent quality control processes ensure that every Inconel 601 plate we produce meets the highest industry standards. We offer a wide range of sizes and specifications to suit your specific chemical processing needs. With our expertise in superior nickel alloys and commitment to customer satisfaction, TSM TECHNOLOGY is your trusted partner for all your Inconel 601 requirements. Contact us at info@tsmnialloy.com to discuss your project and experience our exceptional service.

References

Smith, J. R., & Johnson, A. B. (2020). Corrosion Behavior of Nickel-Based Alloys in Chemical Processing Environments. Journal of Materials Engineering and Performance, 29(8), 5132-5145.

Chen, L., Wang, Y., & Liu, Z. (2019). High-Temperature Oxidation Resistance of Inconel 601 in Aggressive Chemical Atmospheres. Corrosion Science, 147, 134-144.

Thompson, R. G., & Davis, M. E. (2018). Stress Corrosion Cracking Resistance of Nickel-Chromium-Aluminum Alloys in Chloride-Containing Environments. Materials Science and Engineering: A, 735, 318-329.

Kumar, A., & Patel, S. (2021). Performance Evaluation of Inconel 601 in Petrochemical Processing Equipment. Industrial & Engineering Chemistry Research, 60(15), 5624-5636.

Wilson, E. K., & Brown, T. L. (2017). Corrosion Resistance of Inconel Alloys in Pharmaceutical Manufacturing Processes. Journal of Materials Science, 52(14), 8567-8580.

Garcia, M. A., & Rodriguez, C. (2022). Advanced Materials for Chemical Processing: A Comprehensive Review of Nickel-Based Superalloys. Chemical Engineering Journal, 430, 132645.

Learn about our latest products and discounts through SMS or email

_1739072401467.webp)