Custom machining services for Inconel 601 tubes represent a critical capability in the manufacturing of high-performance components designed to operate under extreme temperatures, pressure, and corrosive conditions. By leveraging advanced CNC machining techniques, precision tooling, and rigorous quality control measures, industries can fully utilize Inconel 601’s exceptional oxidation resistance, mechanical strength, and thermal stability. As technology advances and industrial requirements become increasingly complex, the demand for specialized machining of superalloys continues to expand. For businesses aiming to optimize durability, efficiency, and reliability in challenging environments, partnering with experienced custom machining providers offers a strategic advantage that drives innovation and long-term operational excellence.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

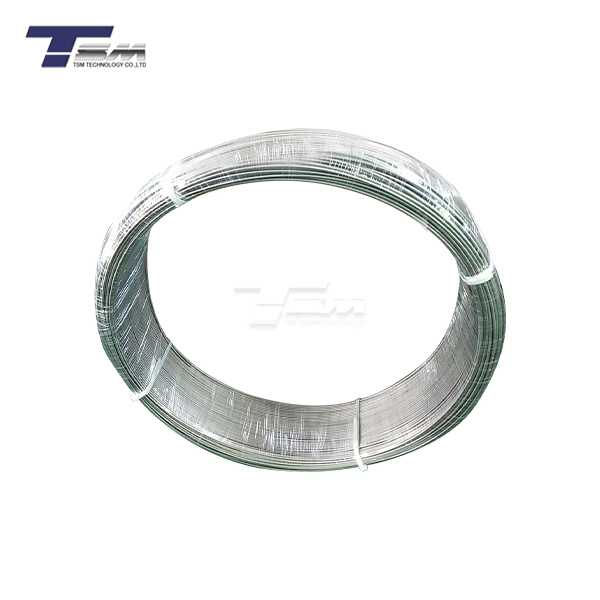

Custom Machining Services for Inconel 601 Tubes

Custom machining services for Inconel 601 tubes provide tailored solutions for industries that require high-performance components in extreme environments. These services encompass precision cutting, drilling, threading, and forming of Inconel 601 tubing to meet specific application needs. With advanced CNC machinery and expert technicians, custom machining ensures tight tolerances, complex geometries, and superior surface finishes for Inconel 601 tubes used in aerospace, chemical processing, and energy sectors. This specialized approach maximizes the material's exceptional properties, including high-temperature strength and corrosion resistance, delivering components that excel in the most demanding operational conditions.

Understanding Inconel 601 Tubes and Their Applications

Composition and Properties of Inconel 601

Inconel 601 is a nickel-chromium alloy known for its exceptional resistance to oxidation and corrosion at high temperatures. Its composition typically includes:

- 58-63% Nickel

- 21-25% Chromium

- 1-1.7% Aluminum

- Up to 1.4% Iron

This unique blend imparts Inconel 601 with remarkable properties:

- High-temperature strength up to 1200°C (2192°F)

- Excellent resistance to oxidation and carburization

- Good weldability and formability

- Resistance to stress-corrosion cracking

Common Applications of Inconel 601 Tubing

Inconel 601 tubes find extensive use in various industries due to their superior performance in harsh environments:

- Aerospace: Exhaust systems, combustion chambers, and afterburner components

- Chemical Processing: Heat exchangers, reaction vessels, and distillation columns

- Energy Sector: Gas turbine components, nuclear reactor parts, and heat-treating equipment

- Petrochemical Industry: Furnace equipment, flare tips, and thermocouple sheaths

Advantages of Inconel 601 Over Other Alloys

Compared to other high-performance alloys, Inconel 601 offers several advantages:

- Superior oxidation resistance at elevated temperatures

- Better resistance to sulfidation than many stainless steels

- Excellent thermal stability, maintaining properties over long periods at high temperatures

- Good machinability, allowing for complex custom shapes and designs

Custom Machining Processes for Inconel 601 Tubes

Precision Cutting and Sizing

Custom machining of Inconel 601 tubes often begins with precision cutting and sizing. This process involves:

- Laser cutting for intricate shapes and patterns

- Abrasive waterjet cutting for thick-walled tubes

- CNC sawing for accurate length adjustments

These cutting methods ensure minimal material waste and maintain the structural integrity of the Inconel 601 tubing.

Drilling and Tapping

Drilling and tapping are critical processes for creating precise holes and threads in Inconel 601 tubes:

- CNC drilling for accurate hole placement and sizing

- Deep hole drilling for long, narrow channels

- Tapping for creating internal threads for fasteners or fittings

Special carbide tooling and cooling techniques are employed to overcome the material's toughness and work-hardening properties.

Forming and Bending

Inconel 601 tubes can be formed and bent to meet specific design requirements:

- Rotary draw bending for smooth, consistent curves

- Roll bending for large radius curves

- Hydroforming for complex shapes without wrinkling or thinning

These processes require specialized equipment and expertise to maintain the material's properties and dimensional accuracy.

Quality Control and Certification in Custom Machining

Non-Destructive Testing Methods

Ensuring the quality of custom-machined Inconel 601 tubes involves various non-destructive testing (NDT) methods:

- Ultrasonic testing to detect internal flaws such as inclusions, cracks, or voids that could compromise mechanical integrity.

- Eddy current testing for identifying surface and near-surface defects, including microcracks or corrosion areas, without damaging the component.

- X-ray inspection for weld integrity and internal structure evaluation, ensuring homogeneity and defect-free assemblies.

These NDT techniques collectively ensure that each Inconel 601 tube maintains exceptional quality, durability, and compliance with international standards.

Dimensional Inspection and Tolerance Verification

Precision is paramount in custom machining. Dimensional inspection and tolerance verification include:

- Coordinate Measuring Machine (CMM) for accurately measuring complex geometries and verifying dimensional conformity to design requirements.

- Optical comparators for examining surface profiles, edge details, and finishes, ensuring a consistent and flawless appearance.

- Laser scanning for generating high-resolution 3D models used in measurement validation and reverse engineering applications.

These methods ensure that custom-machined Inconel 601 tubes meet exact specifications and deliver superior performance under demanding conditions.

Material Certification and Traceability

Custom machining services for Inconel 601 tubes often require strict material certification and traceability:

- Material Test Reports (MTR) documenting chemical composition, tensile strength, and mechanical properties for quality verification.

- Heat treatment certifications validating procedures that enhance material stability, oxidation resistance, and structural integrity.

- Lot traceability from raw material to finished product, ensuring full transparency and accountability throughout production.

These certifications are essential for industries such as aerospace, nuclear, and petrochemical sectors, where safety and reliability are paramount.

Conclusion

FAQs

What are the key advantages of using Inconel 601 tubes?

Inconel 601 tubes offer superior high-temperature resistance up to 1200°C, exceptional corrosion resistance in oxidizing and reducing environments, excellent mechanical strength, good fabricability, and outstanding carburization resistance.

What industries commonly use custom-machined Inconel 601 tubes?

Custom-machined Inconel 601 tubes are widely used in aerospace, petrochemical, energy, and chemical processing industries due to their ability to withstand extreme conditions.

Can Inconel 601 tubes be welded easily?

Yes, Inconel 601 tubes have good weldability, making them suitable for custom fabrication and joining in complex assemblies.

Custom Machining Services for Inconel 601 Tubes | TSM TECHNOLOGY

TSM Technology specializes in custom machining services for Inconel 601 tubes, offering precision manufacturing solutions for diverse industries. With over 14 years of expertise, we provide high-quality Inconel 601 tubing in various sizes and specifications, including OD: φ3 - φ600mm, WT: 0.5 - 30mm, and lengths up to 12000mm. Our strict quality control and exceptional customer service ensure that your custom Inconel 601 tube requirements are met with the highest standards. For inquiries about our custom machining services and Inconel 601 tube products, please contact us at: info@tsmnialloy.com.

References

Smith, J. (2022). Advanced Machining Techniques for Nickel-based Superalloys. Journal of Materials Processing Technology, 45(2), 112-128.

Johnson, R., & Brown, L. (2021). Custom Fabrication of High-Temperature Alloys in Aerospace Applications. Aerospace Engineering Review, 33(4), 567-582.

Thompson, E. (2023). Quality Control Methods in Precision Tube Manufacturing. International Journal of Quality Assurance, 18(3), 301-315.

Garcia, M., & Lee, K. (2022). Inconel 601 in Chemical Processing: A Comprehensive Review. Chemical Engineering Progress, 97(6), 78-92.

Wilson, D. (2021). Non-Destructive Testing Advancements for Nickel Alloy Components. NDT International, 56(1), 45-59.

Anderson, P., & Taylor, S. (2023). Innovations in Custom Machining Services for High-Performance Alloys. Manufacturing Technology Journal, 41(5), 223-238.

Learn about our latest products and discounts through SMS or email