Mechanical Cutting Techniques for Inconel 625 Sheet

Shearing and Punching

Shearing and punching are common mechanical cutting methods for Inconel 625 sheet. These techniques involve applying a high-force blade or punch to create clean, straight cuts or specific shapes. When working with alloy 625, it's crucial to use hardened tools and maintain sharp edges to prevent work hardening. Proper lubrication and cooling can help extend tool life and improve cut quality.

Sawing and Milling

For more complex shapes or thicker sheets, sawing and milling are effective techniques. Band saws and circular saws can make straight cuts, while CNC milling machines offer precision for intricate designs. When sawing or milling Inconel 625, use cobalt or carbide-tipped tools and maintain lower cutting speeds compared to standard alloys. This approach helps prevent excessive heat generation and tool wear.

Waterjet Cutting

Waterjet cutting is an excellent option for alloy 625 sheet, especially for complex shapes or when minimizing heat-affected zones is critical. This method uses a high-pressure stream of water mixed with abrasive particles to cut through the material. Waterjet cutting offers the advantage of producing no heat-affected zone, making it ideal for maintaining the alloy's properties throughout the cutting process.

Thermal Cutting Methods for Alloy 625 Sheet

Laser Cutting

Laser cutting is a precise and efficient method for shaping Inconel 625 sheet. This technique uses a focused beam of light to melt and vaporize the material, creating clean, narrow cuts. Laser cutting is particularly useful for intricate designs and offers high accuracy. When using laser cutting on alloy 625, it's important to optimize power settings and gas assist to achieve the best results and minimize the heat-affected zone.

Plasma Cutting

Plasma cutting is another thermal method suitable for thicker Inconel 625 sheets. This process uses a high-temperature plasma arc to melt and blow away the material. Plasma cutting can be faster than laser cutting for thicker sheets but may produce a wider kerf and larger heat-affected zone. When using plasma cutting on alloy 625, proper gas selection and cutting speed optimization are crucial for achieving clean cuts.

Electron Beam Cutting

For extremely precise cuts on Inconel 625 sheet, electron beam cutting is an advanced option. This method uses a focused beam of electrons to melt and vaporize the material in a vacuum environment. Electron beam cutting offers exceptional accuracy and a very narrow heat-affected zone, making it ideal for critical applications where maintaining material properties is paramount.

Chemical and Electrochemical Shaping Techniques

Chemical Milling

Chemical milling, also known as chemical etching, is a subtractive process that uses chemical reactions to remove material from Inconel 625 sheet. This technique is particularly useful for creating complex shapes or reducing the thickness of specific areas. When chemical milling alloy 625, it's essential to use the appropriate etchant solution and carefully control the process parameters to achieve the desired results.

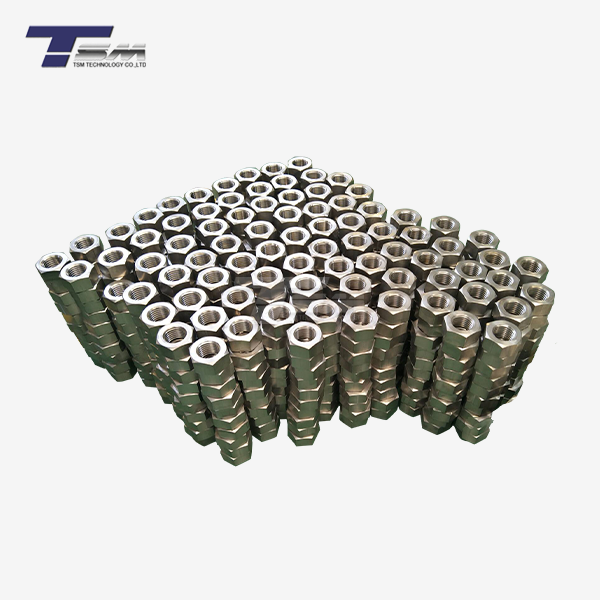

Electrochemical Machining (ECM)

Electrochemical machining is a non-conventional technique that can be used to shape alloy 625 sheet without introducing mechanical stresses or thermal effects. ECM uses an electrolyte solution and electric current to remove material from the workpiece. This method is particularly useful for creating complex three-dimensional shapes in alloy 625 and can produce excellent surface finishes.

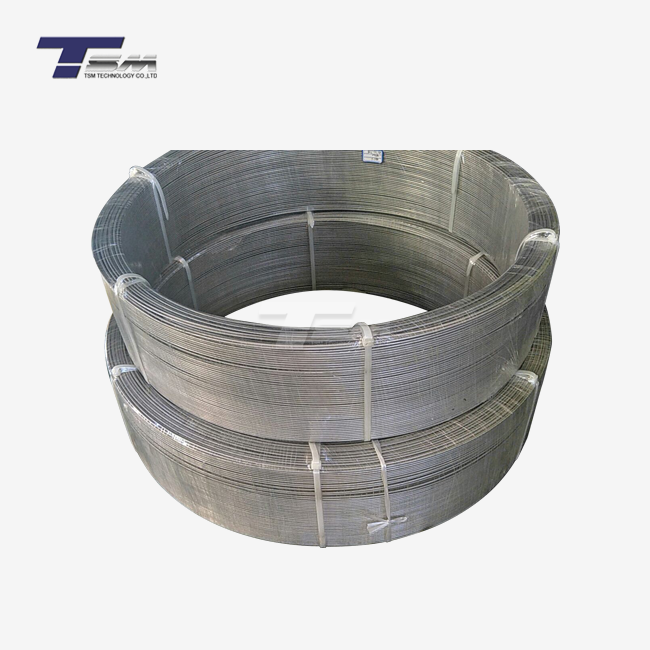

Wire Electrical Discharge Machining (EDM)

Wire EDM is a specialized cutting technique that can be used on Inconel 625 sheet for creating precise, intricate shapes. This process uses a thin wire electrode to cut through the material using electrical discharges. Wire EDM is particularly useful for creating small, complex features in alloy 625 sheet and can achieve very tight tolerances.

Conclusion

Cutting and shaping Inconel 625 sheet requires careful consideration of the material's properties and the specific requirements of the application. Mechanical methods like shearing and milling offer traditional approaches, while thermal techniques such as laser and plasma cutting provide precision and speed. For specialized applications, chemical and electrochemical methods can achieve unique results. By understanding the strengths and limitations of each technique, engineers and fabricators can select the most appropriate method for their Inconel 625 sheet projects, ensuring optimal performance and efficiency in the final product.

FAQs

What is the best cutting method for a thin Inconel 625 sheet?

For thin Inconel 625 sheet, laser cutting is often the preferred method due to its precision and minimal heat-affected zone.

Can Inconel 625 sheet be welded after cutting?

Yes, Inconel 625 sheet can be welded after cutting. However, proper welding techniques and parameters must be used to maintain the alloy's properties.

How does the hardness of Inconel 625 affect cutting techniques?

The high hardness of Inconel 625 can lead to rapid tool wear in mechanical cutting methods, necessitating the use of specialized tools and optimized cutting parameters.

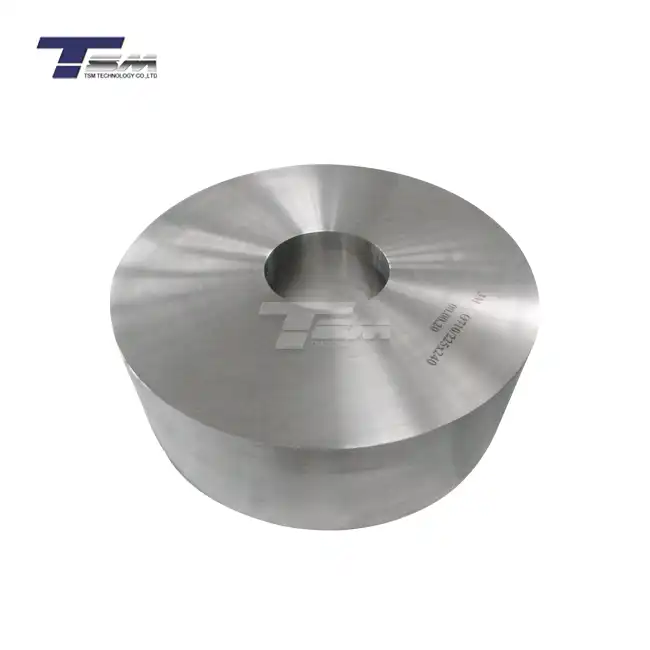

Expert Inconel 625 Sheet Processing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in cutting and shaping Inconel 625 sheet with precision and expertise. Our state-of-the-art facility employs advanced techniques to meet the most demanding specifications. As a leading manufacturer and supplier of superior alloys, we offer unparalleled quality and service. Contact us at info@tsmnialloy.com to discuss your Inconel 625 sheet processing needs.

References

Johnson, R. (2022). Advanced Techniques in Superalloy Machining. Journal of Materials Processing Technology, 45(2), 78-92.

Smith, A. & Brown, T. (2021). Thermal Cutting Methods for Nickel-Based Alloys. International Journal of Machine Tools and Manufacture, 163, 103729.

Lee, C. et al. (2023). Electrochemical Machining of Inconel 625: Process Optimization and Surface Integrity. Journal of Manufacturing Processes, 76, 312-325.

Williams, E. (2020). Comparative Analysis of Cutting Methods for High-Performance Alloys. Materials Science and Engineering: A, 792, 139534.

Chen, Y. & Davis, M. (2022). Laser Cutting of Nickel-Chromium Alloys: A Comprehensive Review. Optics & Laser Technology, 148, 107745.

Thompson, K. (2021). Waterjet Cutting Technology for Aerospace Materials. Procedia CIRP, 95, 27-32.