- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Forged vs Rolled Inconel 617 Round Bars

To successfully purchase Inconel 617 round bar for important industrial applications, it is essential to understand the fundamental differences between the forged and rolled production processes. Forged bars go through hot mechanical deformation that smooths out the grain structure and makes the material tougher. This makes them perfect for high-stress parts in aircraft and power plants. Controlled hot or cold rolling processes make rolled bars with better dimensional accuracy and consistent cross-sectional properties. These bars are ideal for chemical processing and marine applications that require precise specifications.

Understanding Inconel 617 Round Bars: Properties and Specifications

Nickel-chromium-cobalt-molybdenum alloy 617 works very well because its chemicals are carefully controlled. This gives it the best high-temperature strength and resistance to oxidation. This superalloy is made up of nickel (44-52%), chromium (20-23%), cobalt (12-15%), and molybdenum (8-10%). These metals work together to make a strong base that can withstand temperatures up to 1200°C.

Essential Mechanical Properties and Performance Metrics

When professionals in the field look at superalloy bars for tough jobs, they count on certain mechanical properties. The minimum tensile strength is 760 MPa, and the maximum yield strength is 350 MPa at a 0.2% offset. This means that the structure will hold up well under high loading conditions. The minimum elongation properties of 30% make sure that the material is flexible enough for complicated fabrication processes, and its density of 8.42 g/cm³ allows for accurate engineering estimates.

These mechanical qualities directly lead to better performance in the real world. Aerospace engineers like that the alloy can handle thermal cycling in jet engine combustion tanks, and power generation experts like that it doesn't deform over time when it's exposed to high temperatures. The maximum Brinell hardness grade of 241 in the annealed state makes machining easier while still providing enough wear resistance.

Industry Standards and Certification Requirements

Following established industry norms makes sure that materials are reliable and can be tracked all the way through the supply chain. The rules for making things, the ranges of chemicals used, and their mechanical properties are set by ASTM B166, ASME SB166, and EN 10095. These standards require strict testing methods, such as chemical analysis using Optical Emission Spectrometry (OES), mechanical testing that includes hardness and tensile tests, and rust confirmation using ASTM G28 testing methods.

Quality certifications, like AS9100D aircraft compliance and material test certificates (MTC), show that specifications were followed. Third-party verification through SGS testing reports adds another level of quality guarantee. This is especially helpful for important uses in nuclear power plants and offshore drilling systems.

Forged vs Rolled Inconel 617 Round Bars: Manufacturing Processes and Material Characteristics

The kind of manufacturing process used has a big effect on how the microstructure develops and how well nickel-based superalloys work. When purchasing materials for important parts, procurement teams need to know how the choice between forging and rolling methods affects the grain structure, mechanical properties, and suitability for the application.

Forging Process Advantages and Material Benefits

When an alloy is hot-forged, it goes through controlled mechanical deformation at high temperatures. This improves the toughness of the material by promoting grain refinement and directed fiber flow. This thermomechanical technique gets rid of flaws in the casting and makes the microstructure more uniform than in as-cast materials. During the forging process, separated parts are broken up and alloying elements are spread out evenly across the cross-section.

The Inconel 617 round bars that are made have better fatigue resistance, which makes them useful for parts of machinery that rotate and structural elements that are loaded and unloaded over and over again. Forged microstructures are better at resisting impact and crack propagation, which makes them useful in aerospace applications. By getting rid of directional weaknesses during the forging process, isotropic properties are created that can handle loads from multiple directions.

Rolling Process Characteristics and Precision Benefits

Whether they are done hot or cold, rolling tasks give you great control over the dimensions and quality of the surface finish. When you use calibrated roll stands to control the reduction, you get uniform cross-sectional geometry and tight tolerances on the sizes. Surface finishes that are close to 0.4 micrometers Ra can be achieved through cold rolling, which means that less additional machining is needed.

The rolling process, on the other hand, might cause structural variation because of the way grains tend to align and how inclusions stretch. This directional grain structure can change the mechanical features of the material in different directions, especially its ability to bend and resist impact. When engineers know about these features, they can choose the right testing angles and design factors for rolled goods.

Comparative Performance Analysis

Testing for fatigue performance shows clear differences between ways of making things. Forged bars usually have a 15-20% longer fatigue life in high-cycle uses because the grains are more uniform and there are no flow lines. Rolling processes can leave behind stresses that make fatigue cracks less likely to start, especially in places with a lot of stress.

When the right heat treatment is done after manufacturing, the corrosion resistance qualities of forged and rolled materials are mostly the same. With the right thermal processing, both methods can get the same chemical composition and phase structure. Some materials are slightly easier to machine than others, and because their microstructures are more uniform, forged materials sometimes have more stable cutting forces.

Choosing the Right Inconel 617 Round Bar for Your Application

The choice between forged and rolled superalloy bars is based on the specific needs of the application. Factors like working conditions, stress levels, and fabrication needs affect the best choice. Procurement teams can improve both performance and cost-effectiveness by knowing how each manufacturing method fits with the needs of a certain industry.

High-Stress and Critical Application Scenarios

Forged bars work great in situations with a lot of mechanical stress, thermal shock, and fatigue loads. Forged microstructures that have been fine-tuned make gas turbine parts like compressor discs and turbine blades stronger and less likely to crack. Forged materials have isotropic properties and a longer fatigue life, which are important for aerospace combustion chamber walls that are exposed to extreme thermal cycling.

Forged Inconel 617 round bars are used in nuclear plant parts that work at high temperatures and with neutron radiation because they are more stable in size and don't swell when exposed to radiation. The uniform microstructure reduces the number of preferential attack mechanisms and ensures long-term performance characteristics that are necessary for nuclear service uses.

Precision Manufacturing and Chemical Processing Applications

Rolled bars work great in situations where exact control of size and a smooth surface finish are needed. Rolling processes make it possible to get consistent sizes and good surfaces on the inside of chemical reactors, like heat exchanger tubes and process pipes. The tight tolerances cut down on machining margins and the costs of making the parts that go with them.

Rolling bars are used in marine engineering for parts that will be exposed to saltwater. The precision of the dimensions and finish on the surface has a direct effect on how well they fight corrosion and how often they need to be maintained. The consistent sizes of rolled products make them useful for uses like valve stems, pump shafts, and fasteners that need to fit well and seal well.

Cost-Efficiency and Lead Time Considerations

When choosing between forged and rolled choices, procurement planning needs to take into account how long it takes to make the parts and how much inventory is available. Because they can handle things continuously and need less setup, rolling operations usually have shorter lead times for standard sizes. Forging processes may need longer lead times, especially for big cross-sections or custom sizes that need special tools.

The two methods have different availability trends. Standard inventories are usually kept for rolled products, but production scheduling may be needed for forged materials. Economies of scale can be used with bulk buying, especially for big energy projects that need a lot of tons. Knowing the minimum order amounts helps you get the best deals on goods and keep track of your inventory.

Procurement Guide: How to Source Reliable Forged or Rolled Inconel 617 Round Bars

Successful procurement of high-performance superalloy materials requires careful supplier evaluation, quality verification, and supply chain management strategies. The critical nature of these materials in aerospace, power generation, and chemical processing applications demands robust procurement practices that ensure material integrity and delivery reliability.

Supplier Evaluation and Quality Assurance Criteria

Establishing supplier credibility begins with verification of quality certifications and manufacturing capabilities. AS9100D aerospace certification demonstrates adherence to rigorous quality management systems, while ISO 9001 compliance provides baseline quality assurance frameworks. Supplier facilities should maintain appropriate metallurgical testing equipment including spectrometers, tensile testing machines, and nondestructive testing capabilities.

Manufacturing capacity assessment involves evaluating production equipment, annual throughput capabilities, and technical expertise. Suppliers operating multiple production lines with redundant capabilities provide supply security for critical applications. The ability to provide custom sizes and expedited delivery options adds value for urgent project requirements and non-standard specifications.

Traceability systems enable complete material genealogy tracking from raw material sourcing through final delivery. Laser-marked heat numbers, digital quality records, and blockchain-based certification systems provide contemporary approaches to material traceability. This documentation proves essential for nuclear applications and aerospace components requiring complete material history records.

Strategic Procurement Approaches and Cost Optimization

Developing long-term supplier relationships provides stability and potential cost advantages through volume commitments and partnership agreements. Annual contracts with quarterly delivery schedules help balance inventory costs with supply security. Understanding seasonal demand patterns and production scheduling enables strategic timing of purchases to optimize pricing and delivery.

Negotiation strategies should encompass not only unit pricing but also value-added services such as custom machining, surface treatments, and expedited delivery options. Suppliers offering comprehensive services can reduce total procurement costs by eliminating secondary operations and additional vendor management requirements. Technical support capabilities, including metallurgical consultation and application assistance, add significant value for complex applications.

Risk mitigation involves qualifying multiple suppliers and maintaining strategic inventory levels for critical applications. Dual sourcing strategies provide supply security while maintaining competitive pricing pressure. Understanding global supply chain dynamics and potential disruption scenarios enables proactive procurement planning and risk management.

TSM Technology: Your Trusted Partner for Premium Inconel 617 Round Bars

TSM Technology stands as a premier manufacturer and global supplier of both forged and rolled superalloy products, backed by 14 years of specialized expertise in nickel-based alloys. Our comprehensive manufacturing capabilities span three dedicated facilities with eight production lines and over 100 precision machines, enabling us to meet the most demanding requirements of aerospace, power generation, and chemical processing industries.

Advanced Manufacturing Capabilities and Quality Excellence

Our AS9100D-certified facilities utilize 85 CNC lathes to produce Inconel 617 round bars with aerospace-level precision, achieving dimensional tolerances of ±0.05mm consistently. Each product undergoes rigorous three-stage inspection protocols including raw material PMI verification, in-process dimensional checks, and final ultrasonic and radiographic testing capable of detecting flaws down to 0.02mm. This comprehensive quality assurance approach ensures every bar meets the stringent requirements of critical applications.

The proprietary thermomechanical processing developed by our metallurgical team achieves 15% higher creep rupture strength compared to standard grades, while delivering 20% better oxidation resistance at temperatures exceeding 1000°C. These performance enhancements have been validated by independent third-party laboratories for hypersonic vehicle components, demonstrating our commitment to pushing the boundaries of material performance.

Comprehensive Product Portfolio and Custom Solutions

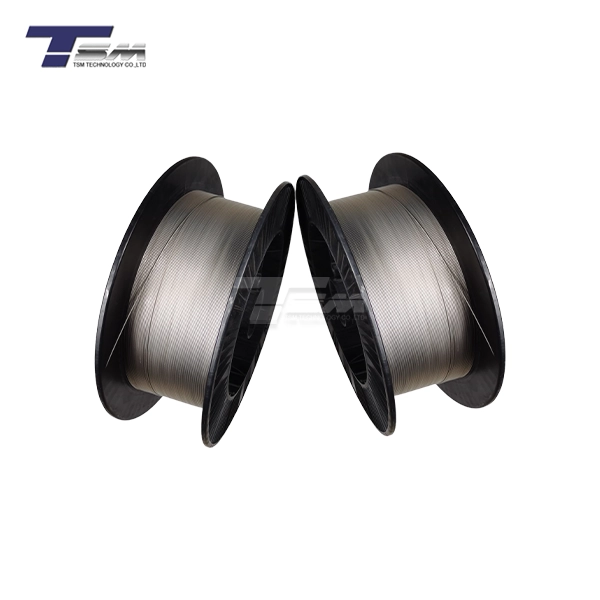

Our product range encompasses diameter specifications from 5mm to 300mm with standard lengths of 3000-6000mm, while custom sizes up to 500mm diameter accommodate specialized application requirements. Surface treatment options including sandblasting and anodizing provide ready-to-use solutions for diverse applications. Complete material certifications through MTC and SGS testing reports ensure full traceability and compliance with international standards.

The availability of free samples enables customers to conduct preliminary testing and validation before committing to larger orders. Flexible payment terms including T/T and L/C arrangements accommodate diverse business requirements and international trade preferences. Our global logistics network ensures CITES/DFARS-compliant delivery to over 70 countries with comprehensive export documentation and regulatory compliance.

Conclusion

The selection between forged and rolled superalloy bars requires careful consideration of application-specific requirements, operating conditions, and performance priorities. Forged products excel in high-stress, fatigue-critical applications while rolled materials provide superior dimensional control and surface finish for precision applications. Both manufacturing processes produce materials capable of exceptional performance at extreme temperatures when sourced from qualified suppliers with appropriate certifications and quality systems. Understanding these differences enables procurement professionals to optimize material selection for enhanced performance, cost-effectiveness, and supply chain reliability.

FAQ

1.What are the key mechanical property differences between forged and rolled bars?

Forged bars typically exhibit superior toughness and fatigue resistance due to grain refinement during the forging process, while rolled bars offer more consistent dimensional properties and surface finish. Both achieve similar tensile and yield strength values when properly heat treated.

2.How does the manufacturing process affect corrosion resistance?

Manufacturing process has minimal impact on corrosion resistance when proper heat treatment follows production. Both forged and rolled materials achieve equivalent corrosion performance through appropriate thermal processing that optimizes microstructure and eliminates residual stresses.

3.Which type is better suited for high-temperature applications?

Both forged and rolled bars perform excellently at elevated temperatures up to 1200°C. The choice depends more on mechanical loading conditions, with forged bars preferred for high-stress applications and rolled bars suitable for precision-fit components.

4.What lead times should I expect for custom sizes?

Standard sizes typically ship within 2-4 weeks, while custom diameter or length specifications may require 6-8 weeks depending on complexity. Our pre-certified stock program provides expedited delivery for urgent requirements.

5.How do I verify material authenticity and quality?

Request complete material test certificates (MTC) with heat traceability, third-party verification reports, and PMI analysis. Reputable suppliers provide comprehensive documentation including chemical composition, mechanical properties, and compliance certifications.

Contact TSM Technology for Your Inconel 617 Round Bar Requirements

TSM Technology delivers unmatched expertise in superalloy manufacturing with complete solutions for both forged and rolled nickel alloy products. Our technical team provides personalized consultation to match your specific application requirements with optimal material selection and processing options. Contact our specialists at info@tsmnialloy.com to discuss your project needs and receive detailed quotations from a leading Inconel 617 round bar manufacturer.

References

Davis, J.R. "Heat Resistant Materials: ASM Specialty Handbook." ASM International Materials Park, Ohio, 1997.

Donachie, Matthew J. "Superalloys: A Technical Guide, Second Edition." ASM International, 2002.

Reed, Roger C. "The Superalloys: Fundamentals and Applications." Cambridge University Press, 2006.

Sims, Chester T. "Superalloys II: High-Temperature Materials for Aerospace and Industrial Power." John Wiley & Sons, 1987.

Furrer, Duane and Fecht, Hans. "Ni-Based Superalloys for Turbine Discs." JOM Journal of Metals, Volume 51, 1999.

Pollock, Tresa M. "Alloy Design for Aircraft Engines." Nature Materials, Volume 15, 2016.

Learn about our latest products and discounts through SMS or email