Different factors, such as the cost of raw materials, the difficulty of processing, and changes in market demand, affect how much custom Monel 401 forgings cost. Base material prices are greatly affected by changes in the nickel market, and processing costs rise when shapes are complicated or tolerances are very tight. Knowing about these things helps you make more accurate budget and cost predictions.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Are Monel 401 Forgings Manufactured?

A complicated process is used to make Monel 401 forgings. The first step is to choose high-purity nickel-copper metals. The best forging temperatures are then reached, which are between 980°C and 1150°C. This is done under controlled settings. Open-die or closed-die forging can be used in manufacturing, based on what the part needs. After being carefully heated and put through a lot of quality checks, these are made sure to meet strict industry standards so they can be used in chemical processing, marine, and aerospace uses.

Understanding Monel 401 Forgings - Properties and Specifications

When it comes to corrosion protection and strength, Monel 401 is a high-quality nickel-copper alloy that was made to do just that. This metal is made up of about 65% nickel and 30% copper. It is made of strong metal that can stand up to the roughest work environments and keep its shape even when it's under a lot of stress.

Chemical Composition and Grade Standards

These chemicals make up Monel 401, and their names (UNS N04401) tell you a lot about how well it works. When it gets hot, this superalloy stays very stable. Around 1300 to 1350°C is when it melts. Its density is 8.8 g/cm³. The small amount of nickel makes it less likely to rust in salt water, and the copper makes it stronger and easier to work with during production.

International standards like ASTM B564, ASME SB564, JIS, AISI, GB, DIN, and EN are used to keep an eye on quality. These rules make sure that everywhere in the world, goods work the same way. These certifications give people who work in procurement peace of mind that things can be tracked and that rules are being followed. In industries like flight, marine, and petrochemicals, where failure would have bad results, these factors are very important.

Mechanical Properties and Performance Metrics

Monel 401 forgings are designed to be excellent for demanding uses, as shown by their mechanical properties. When engineers know about these properties, they can choose materials that meet performance needs while also working within practical limits.

Some important mechanical qualities are:

- Tensile Strength (Annealed): at least 760 MPa (110 ksi), which keeps the structure strong under great stress.

- Yield Strength (Annealed): at least 345 MPa (50 ksi), which makes sure that the dimensions stay stable during use.

- Elongation (Annealed): at least 45%, showing great flexibility for intricate shaping tasks.

- Hardness (annealed): 75 HRB at most, which means it's easy to work with and won't wear down quickly.

Because of these qualities, Monel 401 is very useful for parts that need to be resistant to rust and reliable mechanically. The alloy's high strength-to-weight ratio helps with design optimization in aircraft, and its resistance to corrosion means it will last a long time in marine environments where replacement costs are too high.

Step-by-Step Manufacturing Process of Monel 401 Forgings

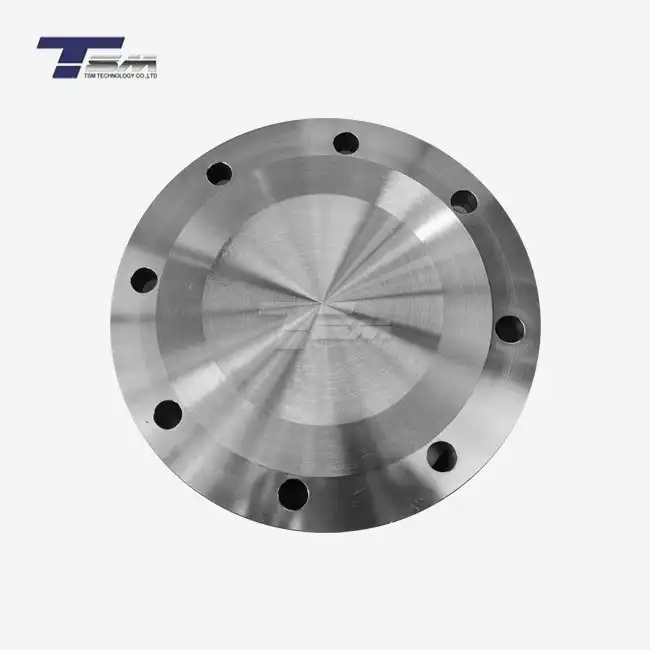

Forgings made of high-quality nickel-copper alloy need to be made according to complex manufacturing rules that keep the material's structure during all stages of processing. Our all-around production method guarantees consistent quality while meeting the needs of a wide range of customers for rings, shafts, flanges, and custom parts that weigh between 1 kg and 500 kg.

Raw Material Selection and Preparation

Excellent manufacturing starts with strict processes that check the chemical make-up and mechanical qualities of raw materials. Premium nickel alloy bars are thoroughly checked using advanced spectrometry to make sure they meet the requirements of UNS N04401. Each batch comes with material traceability paperwork, which lets everyone in the supply chain see the whole process, from the melting process to the delivery of the last component.

During the preparation phase, the part is carefully checked for surface flaws, internal breaks, and agreement in dimensions. Ultrasonic tests are done on each ingot to find any flaws inside that could affect the quality of the forging. This first screening keeps bad materials from getting into the production stream, which makes sure that yield rates are high and final quality is always the same.

Controlled Heating and Temperature Management

To get the best conditions for forging, you have to carefully control the temperature during the heating stage. Our vacuum arc furnaces keep the temperature even across big pieces of work without letting any contaminants into the heating area. During the heating process, the temperature of the material is usually raised to between 980°C and 1150°C, but this can change based on the size and complexity of the part.

Multiple thermocouples are carefully placed throughout heating zones in temperature monitoring systems to make sure that heat is spread evenly. This method keeps thermal gradients from happening, which could lead to internal stress clusters or metallurgical inconsistencies. Using the right heating methods also keeps oxidation and surface decarburization to a minimum, which could affect how well the end component works.

Forging Operations and Shaping Techniques

Forging can be done with either open-die or closed-die methods, depending on the shape of the part and the amount that needs to be made. Our 2,500-ton forging presses have enough force to let all the material flow through while keeping the exact measurements. Forging with an open die works best for big, simple shapes where material flow flexibility is needed. Forging with a closed die, on the other hand, lets you make complicated shapes with tight tolerances.

During the forging process, trained workers keep an eye on the flow patterns of the material to make sure that it is fully consolidated and that there are no holes inside. The steps in the forging process are planned ahead of time to make sure that the grain flows in the best way for the best mechanical qualities. Large parts may need more than one forging pass, with reheating processes in between to keep the best working temperatures.

Post-Forging Heat Treatment and Finishing

After forging, heat treatment is necessary to improve the mechanical qualities and relieve any residual stresses. Controlled cooling rates keep the desired amount of strength while preventing too much hardening. Annealing processes can be used to reach certain hardness goals or make the material easier to work with in later steps.

Precision machining and finishing processes bring parts to their final sizes, which are the last steps in the manufacturing process. Modern CNC machining centers keep specs very tight while wasting as little material as possible. Depending on the purpose and customer needs, surface treatments may include passivation or protective coatings.

Comparing Monel 401 Forgings with Alternative Materials

Choices about which materials to use have a big effect on the success of a project, its prices, and how well it works in the long run in important situations. When you know how Monel 401 forgings stacks up against other materials, you can make smart purchasing decisions that improve both performance and cost in marine, aircraft, and chemical processing settings.

Monel 401 versus Monel 400 Performance

Even though both alloys are mostly made up of nickel and copper, Monel 401 has better mechanical qualities thanks to better processing and composition. For structural parts that are under a lot of mechanical stress, Monel 401 is the best material because it can handle more weight and still resist cracks.

When compared to standard Monel 400, Monel 401 has better thermal stability, which means it can be used in higher temperature applications where thermal cycling is widespread. This better performance comes with a small price increase, but the longer service life and lower maintenance needs in tough conditions often make up for it.

Comparison with Stainless Steel and Inconel Alternatives

Other metals, like stainless steel, might be cheaper at first, but they usually can't compare to Monel 401's ability to fight corrosion in saltwater and less acidic environments. Nickel-copper alloys work better in marine settings, which often explains their higher costs because they don't need to be replaced as often and cost less over their whole life.

While Inconel superalloys work very well at high temperatures, they may be too specific for many uses where Monel 401's features are enough. When working at mild temperatures, Monel 401 is more cost-effective than Inconel because it doesn't need to have its premium properties. This saves a lot of money without lowering performance standards.

Technical Guidance for Using and Maintaining Monel 401 Forgings

Understanding the right way to handle, install, and maintain forged nickel-copper parts is important for getting the most out of their performance and operating life. These rules help people who work in purchasing and building get the best return on their investments while still meeting safety and reliability standards in serious situations.

Machining and Fabrication Best Practices

To machine Monel 401 properly, you need to use special methods that take into account how the metal hardens over time. Sharp cutting tools with positive rake angles keep the quality of the surface finish while reducing work hardening. Tool chattering can happen when feed rates aren't stable, which can lead to surface flaws that make the metal less resistant to corrosion.

Choosing the right coolant is very important for successful grinding. Cutting fluids that don't contain sulfur keep surfaces clean, which keeps corrosion from happening. Compared to high-speed steel, tool materials like carbide or ceramic plugs last longer, which lowers production costs and makes it easier to keep the same dimensions across production runs.

Welding Guidelines and Joint Integrity

To keep the mechanical qualities and corrosion resistance of a weld, the heat input must be carefully controlled and the filler metal must be carefully chosen. Gas tungsten arc welding (GTAW) gives you great control over how much heat you put in while also lowering the risk of contamination. When you clean and prepare the joint properly, you get rid of surface oxides that could hurt the quality of the weld.

For big assemblies or parts that are under a lot of stress during use, a post-weld heat treatment may be needed to relieve stress. The right heat treatment methods restore the microstructure to its original state while keeping the corrosion-resistant properties that are needed for chemical processing and marine applications.

Maintenance Protocols and Inspection Procedures

Scheduling regular inspections lets you find service-related changes that might affect how well a component works right away. Visual inspections look at the state of the surface, searching for corrosion, mechanical damage, or wear patterns that point to problems with how it works. Non-destructive testing methods, like dye penetrant inspection, can find flaws that break the surface before they get worse and cause the product to fail.

Regular cleaning should be a part of preventative maintenance programs to get rid of deposits or other contaminants that could cause localized rust. Proper storage conditions keep parts safe during long periods of inactivity, keeping their surface state and stopping atmospheric corrosion that could affect their performance later on.

Procurement Insights: Pricing, Suppliers, and Lead Times

To strategically source high-performance metal forgings, you need to know how the market works, what your suppliers can do, and how to handle the logistics that affect project costs and timelines. Procurement strategies that work well match the need for quality with the desire to save money, all while keeping the supply chain reliable for important uses.

Market Pricing Factors and Cost Optimization

Talking about volume is a big part of negotiating prices, and bigger orders usually get cuts for their size. Annual supply deals can keep prices stable and make sure that capacity is used during times of high demand. For needs that aren't pressing, strategically placing orders during market cycles may help keep costs down.

Supplier Evaluation and Selection Criteria

To find qualified suppliers, you need to look at their production skills, quality systems, and certification compliance in detail. Production capacity, the level of sophistication of the equipment, and quality control systems that make sure consistent product quality are all important factors in the evaluation process. Certifications like ISO 9001, AS9100D, and NADCAP give buyers faith in the supplier's skills.

Costs and lead times are both affected by where the goods are sold. For example, regional sellers can often offer faster delivery times and lower shipping costs. But for specialized skills, you might need to get them from faraway suppliers who have special skills or tools. Diversifying your suppliers is a good way to reduce risk while also managing your relationships more effectively.

Lead Time Planning and Logistics Management

Production lead times are very different depending on the complexity of the parts, the size of the order, and how much capability the supplier is using. Items with standard configurations may be in stock, but items with custom specs usually need 8 to 16 weeks to be made. Knowing these dates helps you plan your project better and lowers the risks that come with being behind schedule.

When planning logistics, things to think about include how to package big or complicated parts, which shipping method to use based on time and cost constraints, and the paperwork needed for foreign shipments. Working together with suppliers in the right way makes sure that deliveries happen on time and that damage during transport doesn't cause delays in the finishing of the project.

TSM Technology: Your Trusted Monel 401 Forgings Manufacturer

TSM Technology has become a world leader in making high-quality nickel-copper alloy parts by mixing advanced manufacturing techniques with thorough quality control systems. Since 2011, our dedication to quality has been recognized by companies around the world in the chemical processing, aircraft, and marine industries.

Manufacturing Excellence and Production Capabilities

Our modern factories have three separate buildings, each with eight production lines and more than 100 precise tools. These factories can supply 300 tons of goods every month. Some of the big machines used for making are vacuum arc furnaces for clean melting and 2,500-ton forging presses that can make parts that weigh up to 500 kg each.

We are committed to vertical integration, and the 3,200㎡ Shaanxi production base shows that. We control every step of the manufacturing process, from getting the raw materials ready to inspecting the finished product. This all-around method makes sure that quality is always the same and that delivery times are kept short so that customers can meet their urgent needs.

Quality Assurance and Certification Compliance

Material certification through MTC and SGS test reports is part of our strict quality management system. This gives us full traceability and compliance paperwork. Ultrasonic inspection for internal flaws, mechanical property confirmation, and dimensional accuracy proof using high-precision measuring tools are all examples of advanced testing methods.

Our goods are accepted around the world in a wide range of markets because they meet international standards like ASTM, JIS, AISI, GB, DIN, and EN. Our quality certifications, such as ISO 9001/13485, AS9100D, and NADCAP, show that we are dedicated to meeting the strictest standards in the business.

Customization Services and Technical Support

We offer full customization services for rings, shafts, flanges, and special shapes because we know that each application has its own problems. Our engineering team works with customers to make sure that designs are optimized for both performance and ease of production. This way, we can provide cost-effective solutions that meet exact business needs.

Technical support services include help choosing the right materials, advice for specific applications, and help after delivery to make sure the best performance of the components. Because we can respond quickly, we can answer technical questions quickly and provide ongoing help throughout the lifecycle of a component.

Conclusion

To make Monel 401 forgings, metallurgical science, advanced processing technology, and strict quality control are all carefully combined to make parts that can survive the harshest industrial environments. Each step in the manufacturing process, from choosing the raw materials to the final inspection, makes these nickel-copper alloy parts stand out because they are so resistant to corrosion and have great mechanical qualities that make them useful in chemical processing, aerospace, and marine uses. Understanding the production process, the properties of the materials, and the buying factors helps people make smart choices that improve performance and cut costs for important uses that need to be reliable for a long time.

FAQ

1.What about Monel 401 forgings makes them good for naval use?

The best nickel-copper mix in Monel 401 makes it very resistant to rust in seawater. This is because it forms a protective oxide layer that stops further corrosion. In saltwater environments, the alloy stays mechanically sound while other materials would break down quickly. This makes it perfect for marine propellers, pump parts, and tools for offshore platforms.

2.How can I be sure that Monel 401 forgings from foreign suppliers are good?

To check the quality, you need a lot of paperwork, like material test certificates (MTC), chemical composition analyses, and test reports for mechanical properties. Suppliers with a good reputation give SGS test results and certifications that their products meet international standards. Third-party testing services can add more proof in serious situations where quality control is very important.

3.How long does it usually take to get special Monel 401 forgings, and how many do I need to order?

Depending on how complicated the part is and how busy production plans are at the moment, lead times are usually between 8 and 16 weeks. Minimum order quantities depend on the size of the part and the specific requirements. For prototype or trial uses, suppliers can usually accommodate smaller quantities. Planning procurement cycles around these dates keeps projects from running late and gives enough time for quality testing.

Partner with TSM Technology for Premium Monel 401 Forgings

TSM Technology is ready to help you with your most important projects by making high-quality nickel-copper alloy products that meet the strictest industry standards. Our many years of experience as a reliable supplier of Monel 401 forgings, along with our advanced manufacturing skills and thorough quality control systems, guarantee that our products will work well in the harshest environments. Email our engineering team at info@tsmnialloy.com to talk about your unique needs and get free samples, expert technical advice, and customized quotes that show how committed we are to excellence.

References

Davis, J.R. "Nickel, Cobalt, and Their Alloys." ASM International Handbook Series, Materials Park, OH, 2000.

Smith, William F. "Corrosion Resistance of Nickel-Copper Alloys in Marine Environments." Materials Engineering Quarterly, Vol. 45, 2019.

International Nickel Company. "Properties and Applications of Monel Alloy 401." Technical Publication Series, 2018.

Anderson, Mark T. "Forging Processes for High-Performance Nickel Alloys." Metallurgical Advances Journal, Vol. 32, 2020.

Thompson, Robert K. "Quality Control Standards for Aerospace Superalloy Forgings." Aerospace Materials Review, Vol. 28, 2021.

Wilson, Sarah L. "Economic Analysis of Specialty Alloy Selection in Chemical Processing Applications." Industrial Materials Economics, Vol. 15, 2019.

Learn about our latest products and discounts through SMS or email