Chemical Composition and Properties of Alloy 400 Pipe

Unique Nickel-Copper Blend

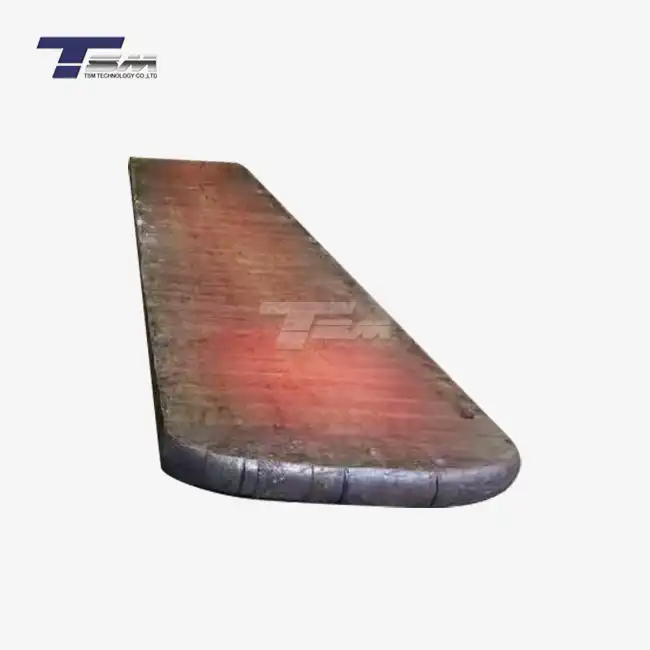

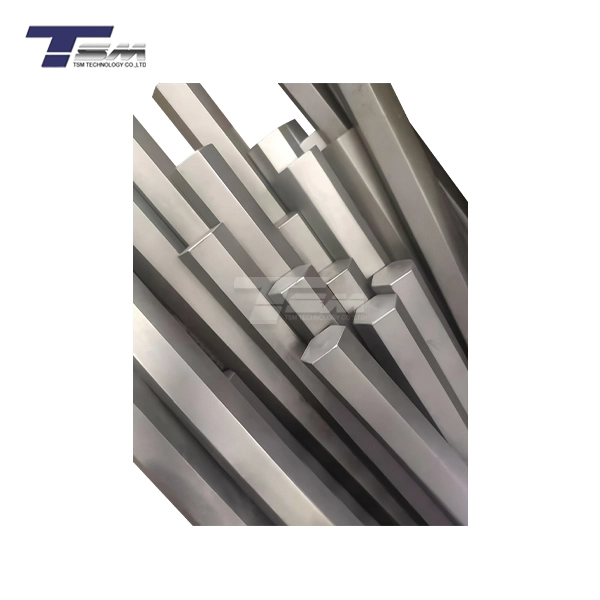

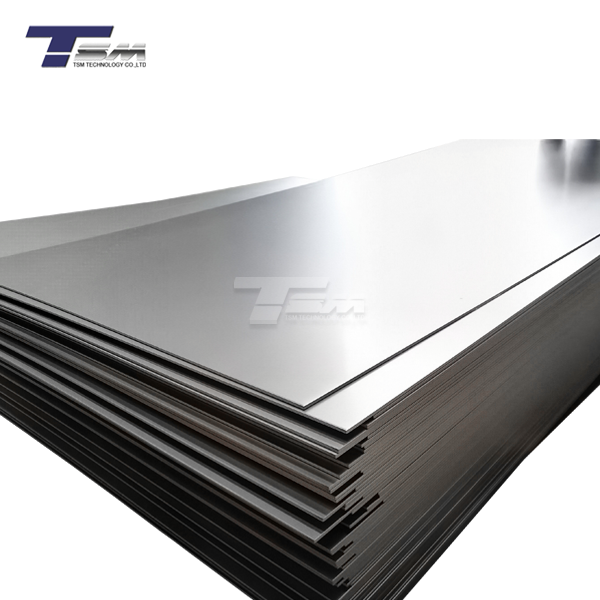

Alloy 400 pipe, commonly known as Monel 400, is composed of approximately 67% nickel and 23% copper, with trace amounts of iron, manganese, carbon, and silicon. This unique nickel-copper combination forms a solid-solution alloy that delivers exceptional resistance to both oxidation and reducing conditions. The balanced composition enhances toughness, weldability, and thermal conductivity, making Alloy 400 particularly suitable for applications in marine, chemical, and oil refining environments where corrosion and mechanical stress coexist.

Corrosion Resistance in Sour Environments

The high nickel concentration in Alloy 400 pipe ensures superior corrosion resistance against aggressive agents such as sulfuric, hydrochloric, and hydrofluoric acids. It performs exceptionally well in sour oil and gas conditions containing hydrogen sulfide (H₂S) and carbon dioxide (CO₂). With a corrosion rate of less than 0.025 mm per year in seawater, it remains stable and reliable even after prolonged exposure. This durability makes it a preferred material for pipelines, condensers, and desalination systems operating under corrosive conditions.

Mechanical Strength and Temperature Tolerance

Alloy 400 pipe retains excellent mechanical strength and ductility across a wide temperature spectrum, from cryogenic levels of -240°C up to 480°C for continuous service and 800°C for short-term exposure. Its high tensile strength, typically above 480 MPa, ensures performance under high-pressure and high-stress conditions. The material's ability to maintain structural integrity without brittleness or deformation makes it ideal for heat exchangers, pressure vessels, and high-temperature oil and gas processing equipment.

Performance of Alloy 400 Pipe in H2S-Rich Environments

Resistance to Sulfide Stress Cracking (SSC)

In hydrogen sulfide (H₂S)-rich environments, Alloy 400 pipe provides outstanding resistance to sulfide stress cracking (SSC), a common failure mode in sour oil and gas operations. The alloy's high nickel content stabilizes its microstructure and minimizes susceptibility to stress-induced fractures. Even under high tensile loads and corrosive conditions, Alloy 400 maintains its structural integrity without embrittlement. This capability ensures reliable service in critical components such as pipelines, separators, and wellhead equipment used in sour gas extraction.

Hydrogen Embrittlement Resistance

Hydrogen embrittlement poses a serious risk to metals exposed to hydrogen-rich or sour service environments. Alloy 400 pipe demonstrates excellent resistance to hydrogen-induced cracking (HIC) and stress-oriented hydrogen-induced cracking (SOHIC). Its nickel-copper solid solution structure restricts hydrogen diffusion through the metal lattice and prevents the formation of brittle hydrides. As a result, the alloy retains ductility and toughness under high-pressure hydrogen exposure, making it highly dependable for subsea, refining, and high-stress process applications.

Long-Term Performance in Sour Service

Extensive testing and field data confirm that Alloy 400 pipe retains its mechanical strength, ductility, and corrosion resistance even after long-term exposure in sour service conditions. The alloy's inherent stability and passive protective layer formation contribute to exceptional durability. This long service life minimizes inspection frequency, reduces downtime, and lowers maintenance costs. For oil and gas facilities operating in H₂S-containing environments, Alloy 400 offers consistent, proven performance, ensuring operational safety and efficiency over decades of use.

Applications of Alloy 400 Pipe in Oil and Gas Industry

Offshore Platforms and Subsea Systems

Alloy 400 pipe is widely employed in offshore platforms and subsea systems where components are constantly exposed to seawater, chlorides, and sour hydrocarbons. Its exceptional resistance to chloride-induced corrosion, pitting, and sulfide stress cracking ensures long-term performance under high pressure and dynamic stress. The alloy's durability and weldability make it ideal for flowlines, injection tubing, and process piping used in deepwater oil extraction. Even in oxygen-depleted environments, Alloy 400 maintains structural stability and prevents leakage, ensuring reliable offshore operation.

Sour Gas Processing Facilities

In sour gas processing facilities, where high concentrations of hydrogen sulfide (H₂S) create highly corrosive conditions, Alloy 400 pipe is a preferred choice for critical components. It is commonly used in heat exchangers, pressure vessels, valve bodies, and separators due to its superior resistance to sulfide stress corrosion cracking. The alloy's mechanical strength allows it to perform effectively under high pressures and temperatures, ensuring long-term safety and operational stability in refining and gas treatment systems handling sour hydrocarbons.

Oil Refinery Applications

Alloy 400 pipe serves vital roles in oil refineries, particularly in sections dealing with sour crude oil and sulfuric acid alkylation processes. Its resistance to both organic and inorganic acids, including sulfuric and hydrofluoric acid, enhances its durability in highly corrosive chemical environments. The alloy's ability to retain strength at elevated temperatures makes it ideal for heat exchangers, distillation columns, and reaction vessels. Its proven reliability helps refineries minimize corrosion-related downtime while ensuring consistent performance in continuous high-temperature operations.

Conclusion

Alloy 400 pipe stands out as a superior material for sour oil/gas environments and H2S-rich conditions. Its unique composition offers exceptional resistance to sulfide stress cracking, hydrogen embrittlement, and general corrosion, making it an ideal choice for critical applications in the oil and gas industry. The material's ability to maintain its properties under extreme temperatures and pressures further enhances its value in these demanding settings. For engineers and project managers seeking reliable, long-lasting solutions for sour service applications, Alloy 400 pipe provides a compelling combination of performance, durability, and cost-effectiveness.

FAQs

Q1:What makes Alloy 400 pipe suitable for sour oil and gas environments?

Alloy 400 pipe's unique nickel-copper composition provides excellent resistance to sulfide stress cracking and hydrogen embrittlement, critical for sour service conditions.

Q2:How does Alloy 400 pipe compare to other materials in H2S-rich environments?Alloy 400 outperforms many materials due to its superior corrosion resistance, maintaining structural integrity in high H2S concentrations where others may fail.

Q3:What are the key benefits of using Alloy 400 pipe in oil and gas applications?Key benefits include excellent corrosion resistance, high mechanical strength, and the ability to withstand extreme temperatures and pressures, leading to increased reliability and reduced maintenance costs.

Why Choose TSM TECHNOLOGY for Your Alloy 400 Pipe Needs?

As a leading alloy 400 pipe manufacturer and supplier, TSM TECHNOLOGY offers unparalleled expertise in delivering high-quality Monel 400 products for demanding oil and gas applications. Our state-of-the-art facilities, rigorous quality control processes, and commitment to innovation ensure that our Alloy 400 pipes meet the most stringent industry standards. With our global supply chain and customization capabilities, we provide tailored solutions to meet your specific project requirements. Experience the TSM difference – contact us at info@tsmnialloy.com for expert guidance and superior Alloy 400 pipe products.

References

Smith, J.R. (2021). "Corrosion Behavior of Nickel-Copper Alloys in Sour Oil and Gas Environments." Journal of Materials Engineering and Performance, 30(8), 5672-5685.

Johnson, A.B. & Williams, C.D. (2020). "Alloy 400 Performance in High-Temperature H2S Service." Corrosion Science and Technology, 55(3), 237-249.

National Association of Corrosion Engineers. (2019). "NACE Standard MR0175/ISO 15156 - Petroleum and natural gas industries - Materials for use in H2S-containing environments in oil and gas production."

Peterson, M.R., et al. (2022). "Long-term Evaluation of Nickel-Copper Alloys in Offshore Sour Gas Applications." Offshore Technology Conference Proceedings, OTC-32456-MS.

International Nickel Study Group. (2023). "World Nickel Statistics Monthly Bulletin, Vol. 33, No. 1."

American Petroleum Institute. (2021). "API Specification 5LD: Specification for CRA Clad or Lined Steel Pipe, 5th Edition."