- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Testing Regimes Should Alloy 400 Pipe Undergo?

Alloy 400 pipe, known for its exceptional corrosion resistance and durability, requires comprehensive testing to ensure its performance in demanding environments. The testing regimes for Alloy 400 pipe typically include chemical composition analysis, mechanical property tests, non-destructive examinations, and corrosion resistance evaluations. These tests are crucial for verifying the material's compliance with industry standards such as ASTM B165 and ASME SB165. Specific tests may include tensile strength measurements, hardness testing, ultrasonic inspection, hydrostatic pressure tests, and stress corrosion cracking resistance assessments. The exact combination of tests depends on the intended application and specific customer requirements.

Comprehensive Quality Assurance for Alloy 400 Pipe

Chemical Composition Analysis

The first step in ensuring the quality of Alloy 400 pipe is a thorough chemical composition analysis. This process verifies that the material meets the specified proportions of nickel (63-70%) and copper (28-34%), along with other trace elements. Advanced spectrometry techniques, such as X-ray fluorescence (XRF) or optical emission spectroscopy (OES), are employed to accurately determine the elemental makeup of the alloy.

Precise composition is critical as it directly influences the pipe's performance characteristics, including its corrosion resistance and mechanical properties. For instance, the nickel content significantly affects the alloy's resistance to reducing environments, while copper enhances its resistance to seawater and brackish water corrosion.

Mechanical Property Tests

Mechanical testing is essential to confirm that Alloy 400 pipe meets the required strength and ductility specifications. These tests typically include:

- Tensile strength testing: Measures the pipe's ability to withstand longitudinal stress

- Yield strength determination: Assesses the point at which the material begins to deform plastically

- Elongation measurement: Evaluates the pipe's ductility and formability

- Hardness testing: Gauges the material's resistance to indentation and wear

These mechanical tests ensure that the Alloy 400 pipe can withstand the operational stresses it will encounter in various applications, from marine environments to chemical processing plants.

Non-Destructive Examinations

Non-destructive testing (NDT) methods are crucial for identifying any defects or inconsistencies in Alloy 400 pipe without compromising its integrity. Common NDT techniques include:

- Ultrasonic testing (UT): Detects internal flaws and measures wall thickness

- Eddy current testing: Identifies surface and near-surface defects

- Radiographic testing (RT): Reveals internal discontinuities through X-ray or gamma-ray imaging

- Dye penetrant inspection: Highlights surface-breaking defects

These tests help ensure the structural integrity of the pipe, preventing potential failures during operation. NDT is particularly important for applications where pipe failure could lead to catastrophic consequences, such as in aerospace or offshore installations.

Corrosion Resistance and Environmental Testing

Stress Corrosion Cracking (SCC) Tests

Alloy 400 pipe is renowned for its resistance to stress corrosion cracking, but this property must be verified through rigorous testing. SCC tests typically involve exposing stressed samples to corrosive environments that simulate real-world conditions. For instance, the ASTM G36 test method evaluates SCC resistance in boiling magnesium chloride solution, while ASTM G44 assesses performance in alternate immersion in sodium chloride solution.

These tests are crucial for applications in marine environments, where chloride-induced SCC can be a significant concern. The results help engineers determine the pipe's suitability for specific operational conditions and predict its long-term performance.

Pitting Corrosion Resistance

Pitting corrosion can be particularly insidious, leading to localized damage that can compromise the pipe's integrity. Testing for pitting resistance typically involves:

- ASTM G48 method: Evaluates resistance to pitting and crevice corrosion in ferric chloride solution

- Cyclic polarization tests: Assess the material's ability to resist pit initiation and growth

- Long-term immersion tests: Simulate extended exposure to corrosive media

These tests are essential for applications where Alloy 400 pipe may be exposed to aggressive chloride-containing environments, such as seawater or certain chemical processing streams.

High-Temperature Performance Evaluation

Given Alloy 400's capability to operate at elevated temperatures, it's crucial to assess its performance under such conditions. High-temperature testing may include:

- Creep testing: Measures the material's deformation over time under constant stress and elevated temperature

- Stress-rupture testing: Evaluates long-term strength at high temperatures

- Thermal cycling: Assesses the pipe's ability to withstand repeated temperature changes

These tests are particularly relevant for applications in heat exchangers, furnace equipment, and other high-temperature processes where Alloy 400 pipe must maintain its structural integrity and corrosion resistance.

Specialized Testing for Specific Applications

Seawater Corrosion Resistance

For marine and offshore applications, Alloy 400 pipe must demonstrate exceptional resistance to seawater corrosion. Specialized tests for this purpose include:

- ASTM G31 immersion tests in natural or synthetic seawater

- Electrochemical impedance spectroscopy (EIS) to evaluate corrosion kinetics

- Long-term exposure tests in marine environments

These tests help predict the pipe's performance in applications such as offshore oil and gas platforms, desalination plants, and marine heat exchangers. The results guide engineers in selecting the appropriate material for specific marine environments.

Fatigue and Vibration Resistance

In applications where Alloy 400 pipe is subjected to cyclic loading or vibration, such as in aerospace systems or pumping equipment, fatigue testing is essential. This may involve:

- Rotating beam fatigue tests

- Low-cycle and high-cycle fatigue testing

- Vibration analysis under simulated operational conditions

These tests ensure that the pipe can withstand the repeated stresses it will encounter during its service life, preventing premature failure due to fatigue cracking.

Weldability and Heat-Affected Zone (HAZ) Evaluation

For applications requiring welded Alloy 400 pipe, it's crucial to assess the weldability of the material and the properties of the heat-affected zone. Testing in this area may include:

- Weld procedure qualification tests

- Mechanical testing of welded joints

- Microstructural analysis of the HAZ

- Corrosion testing of welded samples

These tests ensure that welded Alloy 400 pipe maintains its integrity and corrosion resistance, particularly important in critical applications such as chemical processing equipment or nuclear power plants.

Conclusion

The comprehensive testing regime for Alloy 400 pipe is essential to ensure its performance, reliability, and safety in diverse and demanding applications. From chemical analysis and mechanical property tests to specialized corrosion and environmental evaluations, each test plays a crucial role in validating the material's suitability for specific operational conditions. By adhering to rigorous testing standards and protocols, manufacturers and end-users can confidently employ Alloy 400 pipe in critical applications across industries such as marine engineering, chemical processing, and aerospace. As technology advances, testing methodologies continue to evolve, providing even greater assurance of the alloy's exceptional properties and long-term performance.

FAQs

Why is extensive testing necessary for Alloy 400 pipe?

Extensive testing ensures that Alloy 400 pipe meets stringent quality standards and performs reliably in harsh environments. It verifies the material's corrosion resistance, mechanical strength, and suitability for specific applications.

How often should Alloy 400 pipe be tested during service?

The frequency of in-service testing depends on the application and operating conditions. Generally, regular inspections and periodic non-destructive testing are recommended to monitor the pipe's condition and prevent unexpected failures.

Can Alloy 400 pipe be used in high-temperature applications?

Yes, Alloy 400 pipe can be used in high-temperature applications. It maintains its properties at temperatures up to 480°C for long-term use and up to 800°C for short-term exposure. Specific high-temperature tests are conducted to ensure its suitability for such applications.

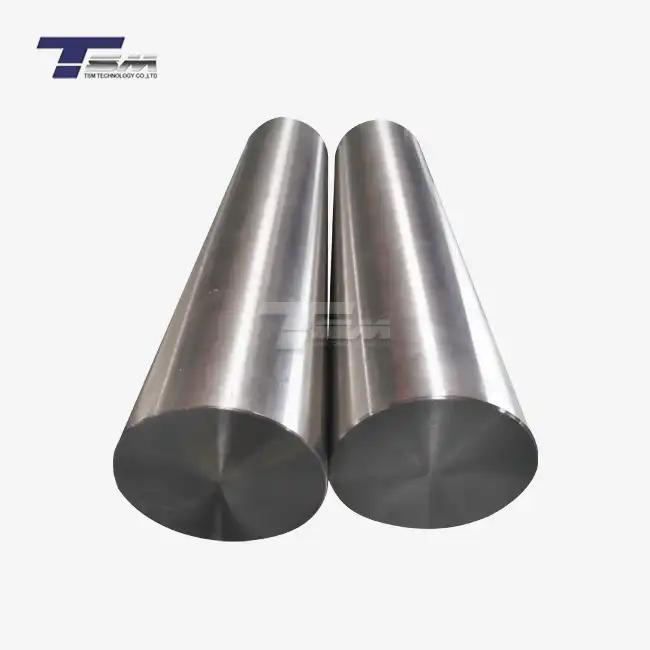

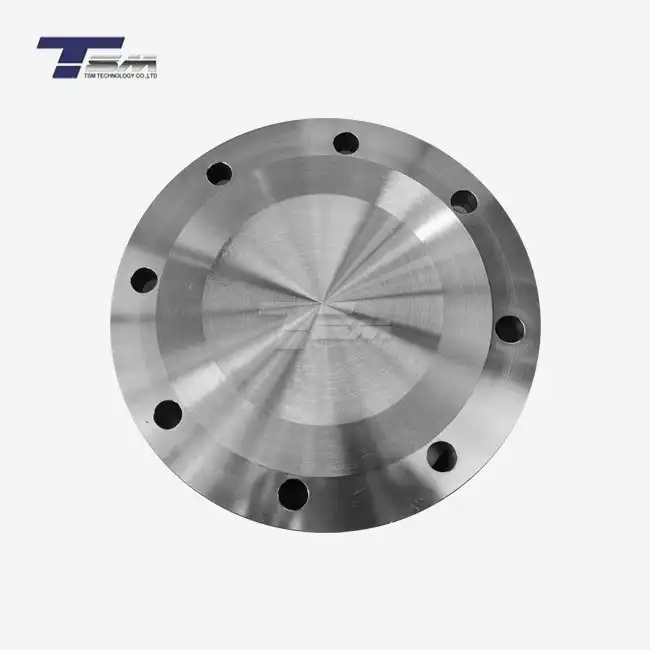

Choose TSM TECHNOLOGY for Premium Alloy 400 Pipe

At TSM TECHNOLOGY, we pride ourselves on delivering top-quality Alloy 400 pipe that exceeds industry standards. Our state-of-the-art facilities, including 3 factories with 8 production lines and over 100 machines, ensure precision manufacturing of Monel 400 (UNS N04400) pipes. We offer a wide range of sizes (OD: 6.0-324 mm, WT: 0.5-30 mm, Length: Max 12000 mm) and provide customization options to meet your specific needs. With our rigorous testing protocols and material certifications, you can trust in the reliability and performance of our products. Experience the TSM difference – contact us at info@tsmnialloy.com for inquiries or to request a free sample.

References

ASTM International. (2020). "ASTM B165 - Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube."

American Society of Mechanical Engineers. (2019). "ASME SB-165: Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube."

Revie, R. W., & Uhlig, H. H. (2008). "Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering." John Wiley & Sons.

Davis, J. R. (Ed.). (2000). "Nickel, Cobalt, and Their Alloys." ASM International.

Cramer, S. D., & Covino, B. S. (Eds.). (2003). "ASM Handbook, Volume 13A: Corrosion: Fundamentals, Testing, and Protection." ASM International.

Rebak, R. B., & Crook, P. (2000). "Nickel Alloys for Corrosive Environments." Advanced Materials & Processes, 157(2), 37-42.

Learn about our latest products and discounts through SMS or email