- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Seamless Tube Extrusion Works in Hot Working?

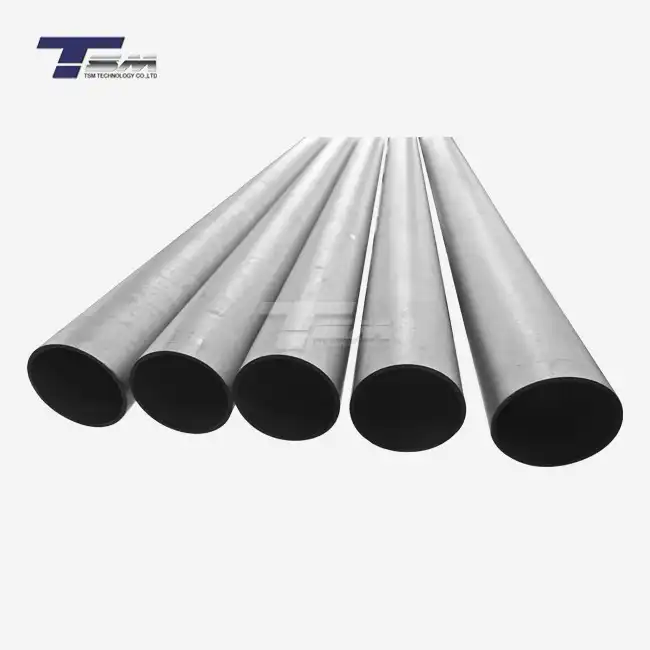

Seamless tube extrusion in hot working is a fascinating process that transforms raw metal into precision-engineered tubes without seams or welds. In this method, a heated metal billet, often made from superior alloys like Monel, Inconel, or Hastelloy, is forced through a die under immense pressure. The elevated temperatures, typically ranging from 800°C to 1300°C, make the metal pliable, allowing it to flow through the die's opening and form a hollow tube. A mandrel inside the die ensures the tube's inner diameter remains consistent, while the outer shape is defined by the die. This technique, integral to hot working, produces durable, high-strength tubes ideal for demanding industries, ensuring exceptional quality and performance.

Understanding the Fundamentals of Seamless Tube Extrusion

The Essence of Hot Working in Metal Forming

Hot working refers to the deformation of metal at elevated temperatures, where the material becomes more ductile and less resistant to shaping. This process is crucial for alloys like Inconel or Hastelloy, which are notoriously tough to manipulate at room temperature. By heating the metal above its recrystallization temperature - often between 800°C and 1300°C, depending on the alloy - manufacturers can mold it into complex shapes without compromising its structural integrity. This pliability reduces the risk of cracking and enhances the material's ability to withstand extreme conditions, making hot working a preferred method for precision engineering applications.

The Role of Extrusion in Seamless Tube Production

Extrusion, as a subset of hot working, involves pushing a heated metal billet through a die to create a continuous shape, such as a tube. In seamless tube production, this process is particularly valuable because it eliminates the need for welds or seams, which can be weak points in a finished product. The absence of seams ensures that the tube can handle high-pressure, corrosive, or high-temperature environments, making it ideal for critical applications. The use of a mandrel - a rod placed inside the die - further refines the process by controlling the tube's inner diameter, ensuring uniformity and precision.

Why Superior Alloys Excel in Hot Extrusion?

Superior alloys, such as those supplied by TSM TECHNOLOGY, are specifically designed to thrive in hot working environments. Materials like Monel, Incoloy, and Hastelloy possess unique properties, including exceptional corrosion resistance, high-temperature strength, and durability. These characteristics make them ideal candidates for seamless tube extrusion, as they can endure the intense heat and pressure of the process without losing their metallurgical integrity. The ability to maintain these properties post-extrusion is what sets superior alloys apart, ensuring that the final product meets the stringent demands of precision engineering and machine shops worldwide.

The Step-by-Step Process of Seamless Tube Extrusion in Hot Working

Preparing the Billet: Heating to Optimal Temperatures

The journey begins with a cylindrical metal billet, typically made from a superior alloy like Inconel or Hastelloy. This billet is heated in a furnace to a temperature that aligns with the alloy's recrystallization point - often between 1000°C and 1200°C for nickel-based alloys. This heating phase is crucial, as it softens the metal, making it malleable enough to flow through the extrusion die. The exact temperature depends on the alloy's composition; Monel, with its high nickel content, may require slightly lower temperatures, while Hastelloy, known for its robustness, might need higher heat to achieve optimal ductility.

Extrusion Through the Die: Shaping the Seamless Tube

Once heated, the billet is transferred to the extrusion press, where it is placed inside a chamber. A powerful ram then applies immense pressure - often exceeding 1000 tons - to force the billet through a specially designed die. Inside the die, a mandrel ensures that the metal forms a hollow tube rather than a solid rod. The die's shape determines the tube's outer diameter, while the mandrel controls the inner diameter, resulting in a seamless tube with precise dimensions. This stage of hot working is both an art and a science, requiring careful calibration to ensure the tube meets exact specifications, such as wall thickness tolerances of ±0.1 mm.

Cooling and Finishing: Ensuring Quality and Precision

After extrusion, the newly formed seamless tube is still at an elevated temperature, making it susceptible to oxidation or distortion if not handled properly. To prevent this, the tube is cooled in a controlled environment, often using air or water quenching, depending on the alloy's properties. Once cooled, the tube undergoes rigorous finishing processes, including straightening, cutting to length, and surface treatment to remove any imperfections. At TSM TECHNOLOGY, each tube is subjected to stringent quality control measures, with professional inspectors ensuring that every product meets the highest standards of precision and durability, ready to serve industries worldwide.

Benefits and Applications of Seamless Tube Extrusion in Hot Working

Enhanced Mechanical Properties Through Hot Working

One of the standout benefits of hot working in seamless tube extrusion is the improvement in the metal's mechanical properties. The high temperatures involved in the process allow the metal's grain structure to recrystallize, eliminating internal stresses and enhancing ductility. This results in tubes that are not only stronger but also more resistant to fatigue and creep, particularly in high-temperature or corrosive environments. For superior alloys like Incoloy or Hastelloy, this means the final product can withstand extreme conditions, such as pressures up to 500 bar or temperatures exceeding 1000°C, making them ideal for demanding applications.

Versatility Across Industries and Applications

Seamless tubes produced through hot working are incredibly versatile, finding use in a wide array of industries. In the aerospace sector, these tubes are integral to hydraulic systems and fuel lines, where their seamless nature ensures leak-proof performance under high pressure. In the oil and gas industry, they are used in downhole tubing and pipelines, where corrosion resistance is paramount. Chemical processing plants rely on these tubes for heat exchangers and reactors, leveraging their ability to handle aggressive media. The global reach of TSM TECHNOLOGY ensures that these high-quality tubes are available to machine shops and engineering firms worldwide, supporting innovation across diverse sectors.

Sustainability and Efficiency in Manufacturing

Beyond performance, seamless tube extrusion in hot working also offers sustainability benefits. The process is highly efficient, producing minimal waste compared to other manufacturing methods, such as welding or machining. The ability to extrude long, continuous tubes reduces the need for additional joining processes, further minimizing material loss. Additionally, the durability of superior alloys means that the resulting tubes have a longer service life, reducing the frequency of replacements and contributing to a more sustainable supply chain. This efficiency aligns with TSM TECHNOLOGY's commitment to innovation, ensuring that their products not only meet performance standards but also support environmentally conscious manufacturing practices.

Conclusion

Seamless tube extrusion in hot working is a remarkable process that combines precision, heat, and advanced materials to create high-performance tubes for critical industries. By leveraging the unique properties of superior alloys, this technique delivers products that excel in strength, durability, and versatility. From aerospace to chemical processing, the applications are vast, and the benefits are undeniable. TSM TECHNOLOGY's dedication to quality and innovation ensures that every seamless tube meets the highest standards, making them a trusted partner for precision engineering needs worldwide.

Contact Us

For more information about our superior alloy products and seamless tube extrusion capabilities, please don't hesitate to contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

Dieter, G. E. (1986). Mechanical Metallurgy. McGraw-Hill.

Kalpakjian, S., & Schmid, S. R. (2014). Manufacturing Engineering and Technology. Pearson.

Groover, M. P. (2010). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. Wiley.

Callister, W. D., & Rethwisch, D. G. (2018). Materials Science and Engineering: An Introduction. Wiley.

Ashby, M. F., & Jones, D. R. H. (2012). Engineering Materials 1: An Introduction to Properties, Applications, and Design. Butterworth-Heinemann.

Totten, G. E., & MacKenzie, D. S. (2003). Handbook of Aluminum: Volume 1: Physical Metallurgy and Processes. CRC Press.

Learn about our latest products and discounts through SMS or email