- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Hot Extrusion Refines Metal Grain Structure?

When it comes to crafting superior nickel alloys and special metals, precision is paramount. One such pivotal technique is hot extrusion, a method that not only molds metal into desired forms but also enhances its internal architecture. But how exactly does hot extrusion refine metal grain structure? In essence, this process involves heating metal billets to elevated temperatures - typically between 1,100°C and 1,300°C for nickel alloys - and forcing them through a die under immense pressure. This dynamic action breaks down coarse, uneven grains, transforming them into a finer, more uniform structure. The result is a material with superior strength, durability, and resistance to extreme conditions, making it ideal for precision engineering applications worldwide.

The Science Behind Hot Extrusion and Grain Refinement

Hot extrusion is more than just a shaping technique - it's a transformative process that redefines the very essence of metal at a microscopic level. To appreciate its impact, we need to delve into the science of how it works and why it matters, especially for high-performance alloys like Monel, Inconel, Incoloy, and Hastelloy, which TSM TECHNOLOGY proudly supplies to global markets.

Understanding Metal Grain Structure

Before exploring the role of hot extrusion, it's crucial to grasp what grain structure means in metals. Every metal is composed of tiny crystalline units called grains, which form during solidification. The size, shape, and orientation of these grains directly influence the metal's mechanical properties, such as strength, ductility, and corrosion resistance. In their raw state, many metals exhibit large, irregular grains, which can lead to weaknesses, especially under stress or in harsh environments. Refining this structure is key to unlocking the full potential of superior alloys.

The Mechanics of Hot Extrusion

Hot extrusion involves heating a metal billet to a temperature where it becomes malleable but not molten, typically around 70-80% of its melting point. For nickel-based alloys, this often means temperatures exceeding 1,100°C. The heated billet is then placed into an extrusion press, where hydraulic forces - sometimes exceeding 1,000 tons - push it through a precisely engineered die. This process elongates the metal, aligning and compressing its internal structure. The intense pressure and heat work in tandem to break down coarse grains, creating a more compact and uniform grain arrangement. This refined microstructure enhances the metal's ability to withstand extreme temperatures, pressures, and corrosive environments, making it indispensable for industries like aerospace, oil and gas, and precision engineering.

Why Grain Refinement Matters?

The benefits of a refined grain structure cannot be overstated. Smaller, more uniform grains lead to improved tensile strength, meaning the metal can endure greater forces without deforming. Additionally, a tighter grain structure enhances fatigue resistance, allowing components to perform reliably under cyclic loading. For alloys like Hastelloy, which are often used in corrosive settings, a refined grain structure also bolsters resistance to chemical degradation. By leveraging hot extrusion, TSM TECHNOLOGY ensures that our superior alloys meet the exacting standards of machine shops and engineering firms worldwide, delivering materials that excel in the most demanding applications.

Hot Extrusion in Action: Enhancing Nickel Alloys

At TSM TECHNOLOGY, hot extrusion is a cornerstone of our commitment to delivering top-tier nickel alloys and special metals. This process is particularly vital for alloys like Monel, Inconel, Incoloy, and Hastelloy, which are prized for their resilience in extreme conditions. Let's explore how hot extrusion is applied in practice and why it's a game-changer for precision engineering.

Tailoring the Process for Nickel Alloys

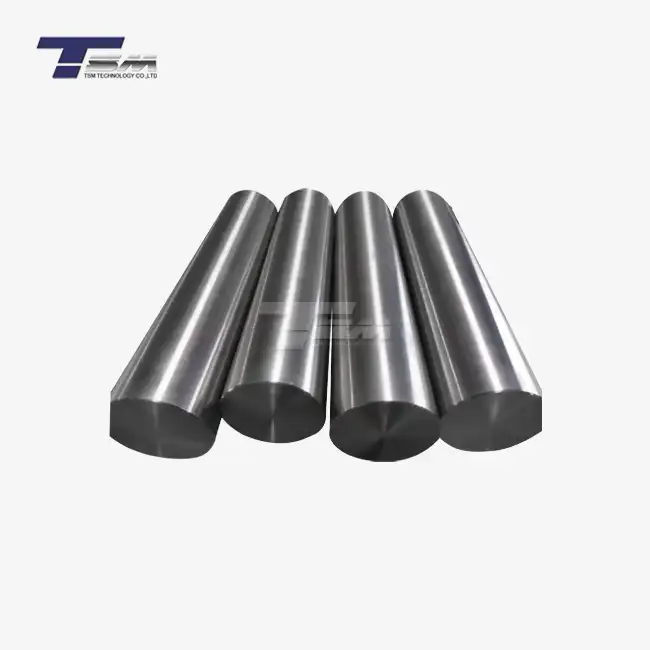

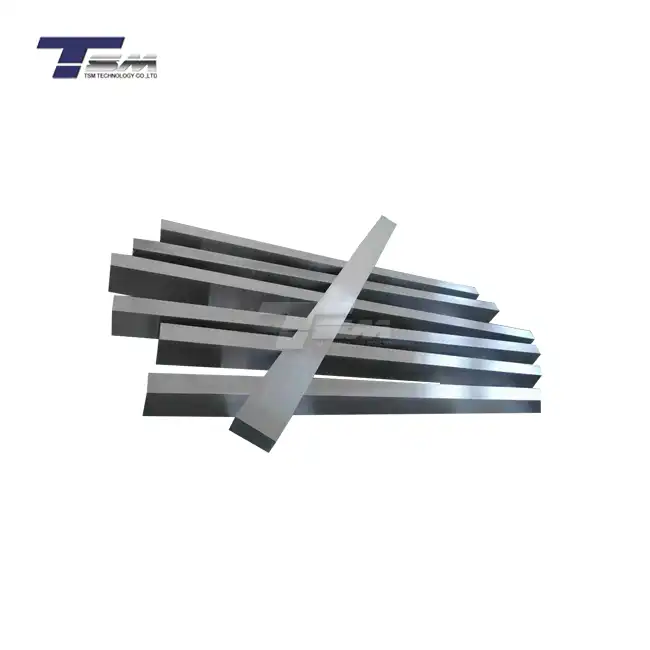

Nickel alloys are renowned for their robustness, but they also present unique challenges during processing due to their high strength and resistance to deformation. Hot extrusion is ideally suited to overcome these hurdles. By carefully controlling parameters such as temperature (typically 1,150°C to 1,250°C for Inconel, depending on the grade) and extrusion speed, we can shape these alloys into complex profiles - such as rods, tubes, and custom sections - while simultaneously refining their grain structure. The dies used in the process are often made from high-strength tool steels or tungsten carbide to withstand the immense forces involved, ensuring precision and consistency in every product.

Real-World Applications of Extruded Alloys

The refined grain structure achieved through hot extrusion translates into tangible benefits across a range of industries. Consider Inconel, a staple in aerospace engineering. Components like turbine blades, which must endure temperatures exceeding 1,000°C and intense mechanical stress, rely on the enhanced strength and fatigue resistance provided by extruded Inconel. Similarly, Monel, often used in marine environments, benefits from a microstructure that resists pitting and crevice corrosion. In the oil and gas sector, Hastelloy tubing, shaped and strengthened through hot extrusion, withstands the corrosive effects of sour gas and high-pressure conditions. These examples underscore why TSM TECHNOLOGY invests in state-of-the-art extrusion technology to meet the needs of our global clientele.

Quality Control in Extrusion

At TSM TECHNOLOGY, quality is non-negotiable. Our hot extrusion processes are subject to rigorous oversight, with every batch of material undergoing meticulous inspection. Parameters such as billet temperature, die alignment, and extrusion pressure are monitored in real time to ensure optimal grain refinement. Post-extrusion, our professional inspectors use advanced techniques, such as ultrasonic testing and metallographic analysis, to verify the integrity of the grain structure. This stringent quality control system ensures that every product - whether a Monel rod or an Incoloy tube - meets the exacting standards of precision engineering, reinforcing our reputation as a trusted supplier of superior alloys worldwide.

Advantages of Hot Extrusion for Precision Engineering

Hot extrusion is not just a manufacturing technique - it's a strategic advantage for industries that demand the highest standards of performance. For precision engineering and machine shops, the benefits of this process extend far beyond grain refinement, offering a suite of advantages that enhance both product quality and operational efficiency. Here's why hot extrusion is indispensable for TSM TECHNOLOGY and our customers.

Superior Mechanical Properties

The primary allure of hot extrusion lies in its ability to enhance the mechanical properties of metals. By refining the grain structure, the process increases yield strength, allowing components to bear heavier loads without deformation. For instance, extruded Inconel 718, a nickel-chromium alloy, can achieve yield strengths exceeding 1,000 MPa, making it ideal for high-stress applications. Additionally, the uniform grain structure improves ductility, enabling the metal to deform without fracturing - a critical attribute for components subjected to dynamic forces. These enhanced properties ensure that TSM TECHNOLOGY's alloys perform reliably in the most arduous conditions, from deep-sea exploration to high-altitude flight.

Versatility in Shapes and Sizes

Hot extrusion offers unparalleled flexibility in shaping metals, enabling the production of intricate profiles that would be impossible or cost-prohibitive with other methods. At TSM TECHNOLOGY, we use this capability to create a diverse range of products, from seamless Hastelloy tubing to custom Incoloy sections. The process allows us to produce long, continuous lengths of material with consistent cross-sections, reducing the need for additional machining and minimizing waste. This versatility is particularly valuable for machine shops, which often require bespoke components tailored to specific applications. By leveraging hot extrusion, we empower our customers to innovate, confident in the knowledge that their materials will meet exacting specifications.

Sustainability and Efficiency

In an era where sustainability is paramount, hot extrusion stands out as an efficient and eco-conscious manufacturing method. The process minimizes material waste by shaping metals in a single, continuous operation, reducing the need for secondary processing. Additionally, the energy required to heat billets is offset by the enhanced properties of the final product, which often leads to longer service life and reduced replacement frequency. At TSM TECHNOLOGY, we are committed to sustainable practices, and our investment in advanced extrusion technology reflects this ethos. By delivering high-quality, long-lasting alloys, we help our customers reduce their environmental footprint while maintaining peak performance.

Conclusion

Hot extrusion is a transformative process that elevates the quality of superior nickel alloys and special metals, making it a cornerstone of TSM TECHNOLOGY's offerings. By refining grain structure, enhancing mechanical properties, and enabling versatile shaping, this technique ensures that our products meet the rigorous demands of precision engineering and machine shops worldwide. From the resilience of Inconel in aerospace to the corrosion resistance of Hastelloy in oil and gas, the benefits of hot extrusion are felt across industries. As we continue to innovate and expand our range of advanced materials, TSM TECHNOLOGY remains dedicated to delivering excellence in every alloy we produce.

Contact Us

For more information on how our superior nickel alloys and special metals can benefit your precision engineering projects, please don't hesitate to reach out. Contact TSM TECHNOLOGY at info@tsmnialloy.com to discuss your specific requirements and discover how our expertise in hot extrusion and grain refinement can elevate your product performance.

References

Dieter, G. E. (1986). Mechanical Metallurgy. McGraw-Hill.

Callister, W. D., & Rethwisch, D. G. (2018). Materials Science and Engineering: An Introduction. Wiley.

Groover, M. P. (2010). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. Wiley.

Kalpakjian, S., & Schmid, S. R. (2014). Manufacturing Engineering and Technology. Pearson.

ASM International. (1990). Metals Handbook, Volume 14: Forming and Forging. ASM International.

Honeycombe, R. W. K. (1984). The Plastic Deformation of Metals. Edward Arnold.

Learn about our latest products and discounts through SMS or email