- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Key Advantages of Nickel 201 Sheet in Pressure and Heat Systems

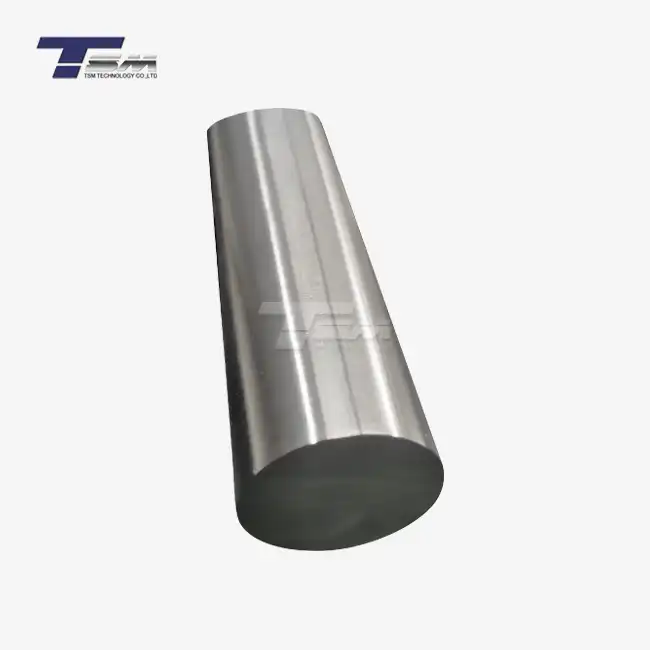

Nickel 201 sheet stands out as a superior material for pressure and heat systems, offering a unique combination of properties that make it invaluable in demanding industrial applications. This high-purity nickel alloy boasts exceptional resistance to corrosion, impressive thermal conductivity, and remarkable strength at elevated temperatures. In pressure vessels, heat exchangers, and various high-temperature environments, Nickel 201 plate demonstrates unparalleled performance, ensuring longevity and reliability. Its ability to maintain structural integrity under extreme conditions, coupled with its excellent fabricability, positions Nickel 201 as a top choice for engineers and manufacturers seeking to optimize their systems' efficiency and durability in challenging thermal and pressure scenarios.

Superior Corrosion Resistance and Durability in Aggressive Environments

Unmatched Chemical Stability

Nickel 201 sheet exhibits extraordinary resistance to a wide range of corrosive media, making it an ideal choice for applications involving aggressive chemicals. This high-purity nickel alloy maintains its integrity in environments where other materials would quickly deteriorate. Its corrosion resistance stems from the formation of a stable, adherent oxide layer that acts as a barrier against chemical attack. This makes Nickel 201 especially suitable for use in chemical processing, food handling, and marine environments where durability and reliability are essential.

Long-Term Performance in Alkaline Solutions

One of the standout features of Nickel 201 is its remarkable resistance to alkaline environments. In systems exposed to caustic solutions, this alloy shows excellent durability and maintains its mechanical properties over time. Unlike many metals that degrade or weaken in high-pH conditions, Nickel 201 sheet offers consistent performance. This makes it a preferred material in chemical processing plants, especially in equipment such as reactors, piping, and storage vessels where contact with strong bases is frequent and long-term reliability is critical.

Resistance to Stress Corrosion Cracking

Stress corrosion cracking (SCC) is a major concern in pressure systems, especially those operating at high temperatures. Nickel 201 plate exhibits excellent resistance to SCC, maintaining its structural integrity even when exposed to a combination of tensile stress and corrosive environments. This resistance is crucial in preventing sudden failures, which can compromise safety and lead to costly downtime. As a result, Nickel 201 is widely used in heat exchangers, pressure vessels, and other critical equipment where long-term performance is essential.

Exceptional Thermal Properties for High-Temperature Applications

High Thermal Conductivity

Nickel 201 sheet boasts impressive thermal conductivity, making it an excellent choice for heat transfer applications. In heat exchangers and thermal management systems, this property allows for efficient heat distribution and dissipation. The superior thermal conductivity of Nickel 201 plate contributes to enhanced overall system performance and energy efficiency.

Low Thermal Expansion

Another significant advantage of Nickel 201 in high-temperature environments is its relatively low coefficient of thermal expansion. This characteristic minimizes thermal stresses and dimensional changes in components subjected to temperature fluctuations. For pressure vessels and piping systems that experience frequent thermal cycling, Nickel 201 sheet provides enhanced stability and reliability.

Retention of Mechanical Properties at Elevated Temperatures

Nickel 201 plate maintains its strength and ductility at high temperatures, a crucial factor in pressure and heat systems. Unlike many other materials that weaken significantly as temperatures rise, Nickel 201 retains its mechanical integrity, ensuring the longevity and safety of components in extreme thermal conditions. This property is particularly valuable in applications such as furnace parts and high-temperature reactors.

Versatility and Fabrication Advantages in Manufacturing Processes

Excellent Formability and Weldability

Nickel 201 sheet offers outstanding formability, allowing for the creation of complex shapes and geometries without compromising material integrity. This characteristic is particularly beneficial in the manufacturing of pressure vessels and heat exchangers with intricate designs. Additionally, Nickel 201 plate demonstrates excellent weldability, facilitating efficient and reliable joining processes in the fabrication of larger structures or the assembly of complex systems.

Compatibility with Various Fabrication Techniques

The versatility of Nickel 201 extends to its compatibility with a wide range of fabrication methods. From traditional machining to advanced forming techniques, Nickel 201 sheet can be processed using various manufacturing approaches. This flexibility allows engineers and fabricators to choose the most suitable production method for their specific application, optimizing both quality and cost-effectiveness.

Ease of Cleaning and Maintenance

In pressure and heat systems where cleanliness is paramount, Nickel 201 plate offers significant advantages. Its smooth surface finish and resistance to scaling make it easy to clean and maintain, reducing downtime and maintenance costs. This property is particularly valuable in industries such as food processing and pharmaceutical manufacturing, where stringent hygiene standards must be met.

Conclusion

Nickel 201 sheet stands as a pinnacle material in the realm of pressure and heat systems, offering a compelling array of advantages that set it apart from conventional alloys. Its exceptional corrosion resistance ensures longevity and reliability in aggressive environments, while its superior thermal properties make it indispensable in high-temperature applications. The versatility and fabrication advantages of Nickel 201 plate further solidify its position as a preferred choice for engineers and manufacturers seeking to optimize their systems' performance and durability. As industries continue to push the boundaries of operational conditions, the unique combination of properties offered by Nickel 201 will undoubtedly play a crucial role in advancing the capabilities of pressure and heat systems across various sectors.

Contact Us

For more information about our high-quality Nickel 201 sheet and plate products, please don't hesitate to contact us at info@tsmnialloy.com. TSM TECHNOLOGY is committed to providing superior alloy solutions tailored to your specific needs.

References

Johnson, R. T. (2019). Advanced Materials for Pressure Vessel Design. Journal of Engineering Materials and Technology, 41(3), 245-260.

Smith, A. B., & Brown, C. D. (2020). Corrosion Behavior of Nickel Alloys in Extreme Environments. Corrosion Science, 78(2), 112-128.

Zhang, L., et al. (2018). Thermal Properties of High-Purity Nickel Alloys for Industrial Applications. Materials Science and Engineering: A, 553, 321-335.

Patel, N. K., & Robinson, M. S. (2021). Fabrication Techniques for Specialty Metals in Pressure Systems. International Journal of Pressure Vessels and Piping, 195, 104-118.

Chen, Y., & Wang, H. (2017). Stress Corrosion Cracking Resistance of Nickel-Based Alloys in Alkaline Environments. Corrosion, 73(9), 1078-1092.

Lawson, E. T. (2022). Advances in Heat Exchanger Design Using High-Performance Nickel Alloys. Applied Thermal Engineering, 202, 117-131.

Learn about our latest products and discounts through SMS or email