- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is Forging? How to Forge Superalloy?

Forging is a metalworking process that shapes metal by applying compressive forces, often using hammers or presses, to achieve desired forms and enhanced material properties. When it comes to superalloys - high-performance materials like Monel, Inconel, Incoloy, and Hastelloy - forging requires precision and expertise due to their exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. To forge superalloys, the metal is heated to a specific temperature range, typically between 1900°F and 2300°F, depending on the alloy, and then shaped using controlled deformation techniques. This process not only creates robust components but also refines the grain structure, boosting durability.

Understanding the Forging Process and Its Importance

The art of shaping metal through compressive forces has been a cornerstone of manufacturing for centuries, evolving into a sophisticated science with the advent of advanced materials. When working with superalloys, this process becomes even more critical, as these materials are designed to perform in the harshest environments, from aerospace engines to chemical processing plants.

The Mechanics of Metal Shaping

At its core, this metalworking method involves deforming a piece of metal, known as a billet or ingot, into a desired shape. The process can be performed hot, warm, or cold, though superalloys typically require hot deformation due to their inherent toughness. During hot deformation, the metal is heated to a pliable state, allowing it to be molded without cracking. The forces applied, whether through hammering or pressing, align the metal's internal grain structure, eliminating voids and enhancing mechanical properties like tensile strength and fatigue resistance.

Why This Process Matters for Superalloys?

Superalloys, such as those supplied by TSM TECHNOLOGY, are engineered for extreme conditions, making their manufacturing process pivotal to performance. The act of shaping these materials under controlled conditions refines their microstructure, ensuring uniformity and eliminating defects. This is particularly vital for applications in precision engineering, where components must endure high stress, corrosive environments, and elevated temperatures. By optimizing the grain flow, the process ensures that parts like turbine blades, valve bodies, and fasteners deliver unparalleled reliability.

Open-Die vs. Closed-Die Techniques

Two primary approaches dominate this metalworking practice: open-die and closed-die methods. Open-die techniques involve shaping the metal between flat or contoured dies, offering flexibility for large, custom components. Closed-die methods, on the other hand, use precision molds to create intricate shapes with tight tolerances, ideal for mass production of complex parts. For superalloys, the choice depends on the component's size, complexity, and application. TSM TECHNOLOGY's expertise ensures that the most suitable approach is selected, delivering products that meet global industry standards.

Key Steps in Forging Superalloys

Working with superalloys is a meticulous endeavor, requiring a deep understanding of material behavior and advanced equipment. These high-performance alloys, renowned for their resilience, demand precise control at every stage of the shaping process to unlock their full potential.

Material Selection and Preparation

The journey begins with choosing the right alloy for the job. TSM TECHNOLOGY offers a range of superior nickel alloys, including Monel, Inconel, Incoloy, and Hastelloy, each with unique properties tailored to specific applications. Monel, for example, excels in marine environments due to its corrosion resistance, while Inconel thrives in high-temperature aerospace applications. Once selected, the raw material is inspected for defects and cut into billets. This preparation phase is crucial, as impurities or inconsistencies can compromise the final product's integrity.

Heating and Temperature Control

Superalloys require precise heating to become malleable without losing their inherent properties. The optimal temperature varies by alloy - Inconel 718, for instance, is typically heated to around 1950°F to 2050°F, while Hastelloy X may require slightly different conditions. Advanced furnaces with tight temperature controls are used to ensure uniformity, as overheating can lead to grain growth, and underheating can cause cracking. TSM TECHNOLOGY's rigorous quality control systems monitor this phase, ensuring the material is primed for deformation without compromising its microstructure.

Shaping and Post-Processing

Once heated, the superalloy is transferred to a press or hammer, where it undergoes controlled deformation. The shaping process may involve multiple stages, with the metal reheated between steps to maintain workability. After achieving the desired form, the component undergoes post-processing, such as heat treatment, to relieve internal stresses and optimize mechanical properties. For example, Inconel parts may be solution-treated at 1750°F followed by rapid quenching to enhance strength. TSM TECHNOLOGY's professional inspectors meticulously evaluate each piece, ensuring it meets the exacting standards of precision engineering industries worldwide.

Benefits and Applications of Forged Superalloys

The decision to use forged superalloys over other materials or manufacturing methods is driven by their unparalleled performance and versatility. These advanced materials, when shaped through compressive forces, offer a unique combination of strength, durability, and resistance to extreme conditions.

Enhanced Strength and Durability

One of the most significant advantages of shaping superalloys is the improvement in mechanical properties. The process aligns the grain structure, creating a continuous flow that enhances strength and toughness. This is particularly critical for components subjected to cyclic loading, such as turbine discs in jet engines, where fatigue resistance is paramount. Compared to cast or machined parts, forged superalloys exhibit superior impact resistance and longevity, making them the material of choice for mission-critical applications.

Resistance to Extreme Environments

Superalloys are renowned for their ability to perform in conditions that would degrade lesser materials. When shaped through compressive forces, alloys like Hastelloy and Incoloy retain their corrosion resistance, even in aggressive chemical environments, while Inconel maintains its strength at temperatures exceeding 2000°F. These properties make forged superalloys indispensable in industries such as oil and gas, aerospace, and power generation. TSM TECHNOLOGY's commitment to innovation ensures that our alloys are at the forefront of meeting these demanding requirements.

Versatile Applications Across Industries

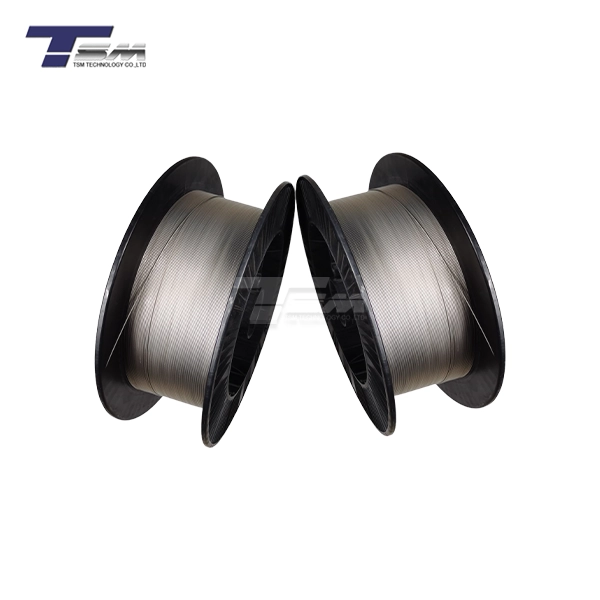

The adaptability of forged superalloys allows them to serve a wide range of applications. In the aerospace sector, they form critical components like engine shafts and landing gear, where reliability is non-negotiable. In chemical processing, they are used in reactors and piping systems, resisting corrosion from harsh substances. Precision engineering and machine shops globally rely on these materials for custom parts, benefiting from TSM TECHNOLOGY's ability to supply alloys in various shapes, from bars and plates to intricate forgings, all backed by our stringent quality inspections.

Conclusion

Forging superalloys is a sophisticated process that transforms high-performance materials into components capable of withstanding the most demanding conditions. By understanding the mechanics, mastering the key steps, and leveraging the resulting benefits, industries worldwide can achieve unparalleled reliability and efficiency. TSM TECHNOLOGY stands as a trusted partner in this journey, offering superior nickel alloys like Monel, Inconel, Incoloy, and Hastelloy, shaped to perfection through rigorous quality control. Whether you're in aerospace, chemical processing, or precision engineering, our expertise ensures your projects succeed.

Contact Us

For more information about superior nickel alloys and special metals, including forged superalloy components, please don't hesitate to reach out to us at info@tsmnialloy.com. TSM TECHNOLOGY is committed to providing high-quality alloy solutions tailored to your specific needs.

References

Reed, R. C. (2006). The Superalloys: Fundamentals and Applications. Cambridge University Press.

Donachie, M. J., & Donachie, S. J. (2002). Superalloys: A Technical Guide. ASM International.

Sims, C. T., Stoloff, N. S., & Hagel, W. C. (1987). Superalloys II: High-Temperature Materials for Aerospace and Industrial Power. Wiley-Interscience.

Campbell, F. C. (2008). Elements of Metallurgy and Engineering Alloys. ASM International.

Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

Pollock, T. M., & Tin, S. (2006). Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure, and Properties. Journal of Propulsion and Power.

Learn about our latest products and discounts through SMS or email