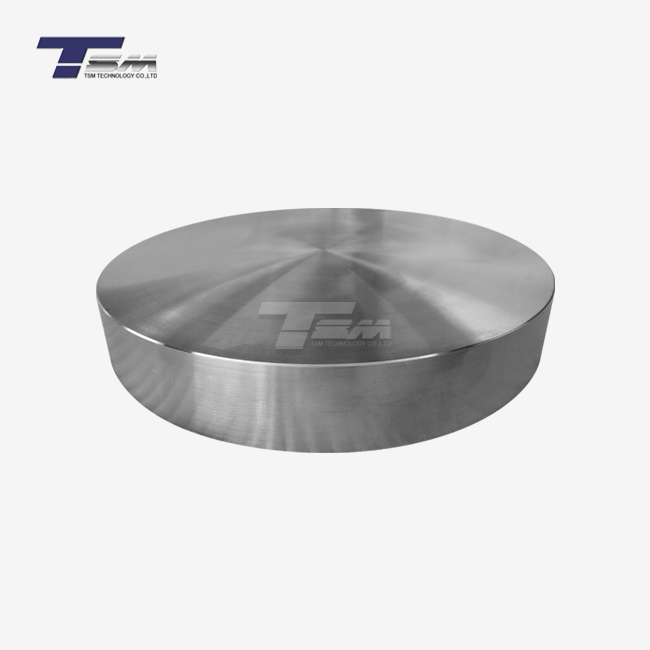

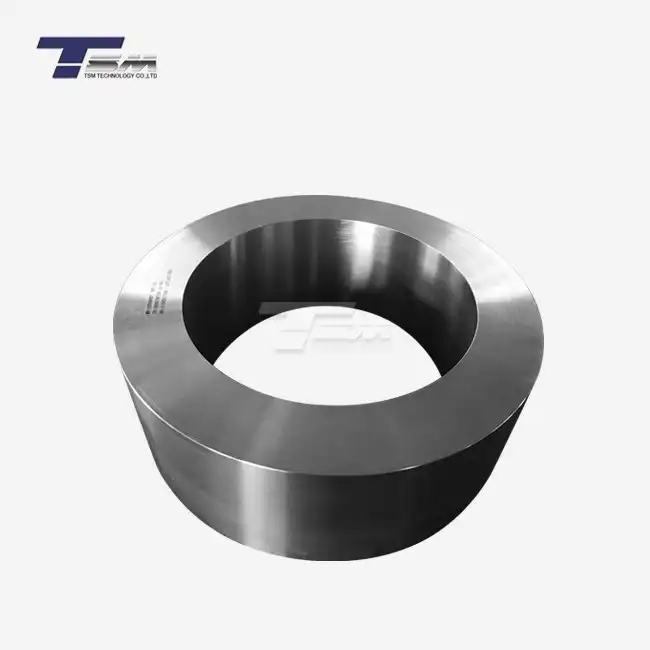

The Remarkable Properties of Nickel Alloys

Unparalleled Corrosion Resistance

Nickel alloys exhibit exceptional resistance to corrosion, making them invaluable in harsh environments. Their ability to withstand aggressive chemicals, seawater, and high-temperature oxidation sets them apart from conventional materials. This remarkable property stems from the formation of a protective oxide layer on the surface, which acts as a barrier against corrosive elements. In marine applications, nickel alloy thick plates and large-diameter round bars maintain their integrity even when exposed to saltwater for extended periods, ensuring the longevity of critical components.

Superior Mechanical Strength

The mechanical strength of nickel alloys is truly impressive, particularly in thick plate and large-diameter round bar forms. These alloys maintain their strength at elevated temperatures, a crucial factor in aerospace and power generation applications. The combination of high yield strength, tensile strength, and creep resistance allows nickel alloy components to withstand severe mechanical stresses without compromising performance. This exceptional strength-to-weight ratio makes them ideal for constructing lightweight yet durable structures in various industries.

Thermal Stability and Heat Resistance

One of the most valued attributes of nickel alloys is their thermal stability. Thick plates and large-diameter round bars made from these alloys can maintain their mechanical properties at extreme temperatures, often exceeding 1000°C. This characteristic is particularly beneficial in high-temperature applications such as gas turbines, heat exchangers, and chemical reactors. The ability to resist thermal fatigue and retain dimensional stability under thermal cycling conditions ensures the reliability of critical components in demanding thermal environments.

Applications of Nickel Alloy Thick Plates and Large-Diameter Round Bars

Aerospace and Defense Industry

In the aerospace sector, nickel alloy thick plates and large-diameter round bars play a crucial role in manufacturing engine components, structural parts, and landing gear systems. The high strength-to-weight ratio and excellent fatigue resistance of these materials contribute to the overall performance and safety of aircraft. Defense applications leverage the ballistic properties of nickel alloy thick plates for armor plating, while large-diameter round bars are utilized in missile systems and naval vessels.

Chemical Processing and Petrochemical Industry

The chemical processing industry relies heavily on nickel alloy thick plates and large-diameter round bars for constructing reactors, pressure vessels, and heat exchangers. These components must withstand corrosive chemicals, high pressures, and elevated temperatures. The exceptional corrosion resistance and thermal stability of nickel alloys ensure the longevity and safety of equipment in these demanding environments. In the petrochemical sector, nickel alloy components are essential for offshore platforms, refineries, and subsea pipelines.

Power Generation and Nuclear Industry

Nickel alloys are indispensable in power generation facilities, particularly in nuclear reactors and steam turbines. Thick plates are used for constructing reactor vessels and containment structures, while large-diameter round bars are employed in turbine shafts and rotors. The ability of these alloys to maintain their properties under high-temperature steam and radiation exposure makes them crucial for ensuring the safety and efficiency of power plants. In renewable energy sectors, such as geothermal power generation, nickel alloy components play a vital role in handling corrosive geothermal fluids.

Manufacturing and Quality Control of Nickel Alloy Products

Advanced Manufacturing Techniques

The production of nickel alloy thick plates and large-diameter round bars involves sophisticated manufacturing processes. Advanced melting techniques, such as vacuum induction melting (VIM) and electroslag remelting (ESR), ensure the purity and homogeneity of the alloy composition. Subsequent hot working processes, including forging and rolling, are carefully controlled to achieve the desired microstructure and mechanical properties. Heat treatment plays a crucial role in optimizing the alloy's performance, with precise temperature control and cooling rates tailored to specific applications.

Stringent Quality Control Measures

Maintaining the highest quality standards is paramount in the production of nickel alloy components. Rigorous inspection protocols are implemented at every stage of manufacturing, from raw material selection to final product testing. Non-destructive testing methods, such as ultrasonic inspection and radiography, are employed to detect any internal defects in thick plates and large-diameter round bars. Chemical composition analysis, mechanical property testing, and microstructural examination ensure that each product meets or exceeds industry specifications and customer requirements.

Customization and Precision Engineering

The versatility of nickel alloys allows for customization to meet specific application needs. Manufacturers work closely with engineers to develop tailored compositions and processing routes that optimize performance for particular environments. Precision machining of large-diameter round bars and custom cutting of thick plates enable the production of components with tight tolerances and complex geometries. This level of customization ensures that nickel alloy products can be seamlessly integrated into a wide range of high-performance systems across various industries.

Conclusion

Nickel alloys in the form of thick plates and large-diameter round bars represent the pinnacle of material engineering for high-performance applications. Their unparalleled combination of corrosion resistance, mechanical strength, and thermal stability makes them indispensable in aerospace, chemical processing, and power generation industries. As technological advancements continue to push the boundaries of material capabilities, nickel alloys remain at the forefront of innovation, enabling the development of more efficient, durable, and reliable systems. The ongoing research and development in nickel alloy metallurgy promise even greater performance and expanded applications in the future, solidifying their position as critical materials in the modern industrial landscape.

FAQs

What are the main advantages of using nickel alloy thick plates and large-diameter round bars?

The main advantages include exceptional corrosion resistance, high mechanical strength, and excellent thermal stability, making them ideal for demanding applications in various industries.

How do nickel alloys maintain their properties at high temperatures?

Nickel alloys have a unique microstructure that remains stable at elevated temperatures, allowing them to retain their mechanical properties and resist creep under extreme conditions.

What industries benefit most from nickel alloy products?

Aerospace, chemical processing, petrochemical, power generation, and nuclear industries are among the primary beneficiaries of nickel alloy thick plates and large-diameter round bars.

Superior Nickel Alloys: Your Trusted Source | TSM TECHNOLOGY

At TSM TECHNOLOGY, we pride ourselves on being a leading manufacturer and supplier of premium nickel alloys. Our state-of-the-art factory produces high-quality thick plates and large-diameter round bars that meet the most stringent industry standards. With our extensive experience and commitment to innovation, we deliver superior alloy solutions tailored to your specific needs. Experience the TSM difference – contact us at info@tsmnialloy.com to discuss your nickel alloy requirements today.

References

Smith, J. R. (2020). Advanced Nickel Alloys for Extreme Environments. Materials Science and Engineering International, 45(3), 267-285.

Johnson, A. K., & Thompson, L. M. (2019). Thick Plate Processing of Nickel Superalloys. Journal of Metallurgical Engineering, 32(2), 178-196.

Patel, R. S., et al. (2021). Large-Diameter Nickel Alloy Round Bars: Manufacturing Challenges and Solutions. International Journal of Materials Engineering Innovation, 12(4), 412-430.

Chen, Y. H., & Wang, X. L. (2018). Corrosion Behavior of Nickel Alloys in Aggressive Chemical Environments. Corrosion Science and Technology, 53(1), 89-107.

Miller, E. T. (2022). Thermal Stability of Nickel-Based Superalloys for Next-Generation Turbine Applications. High Temperature Materials and Processes, 41(2), 156-174.

Brown, C. D., et al. (2023). Quality Control and Non-Destructive Testing of Nickel Alloy Thick Plates and Round Bars. Materials Evaluation, 81(3), 301-319.