- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Packaging and Shipping Monel 401 Bars: Preventing Surface Damage

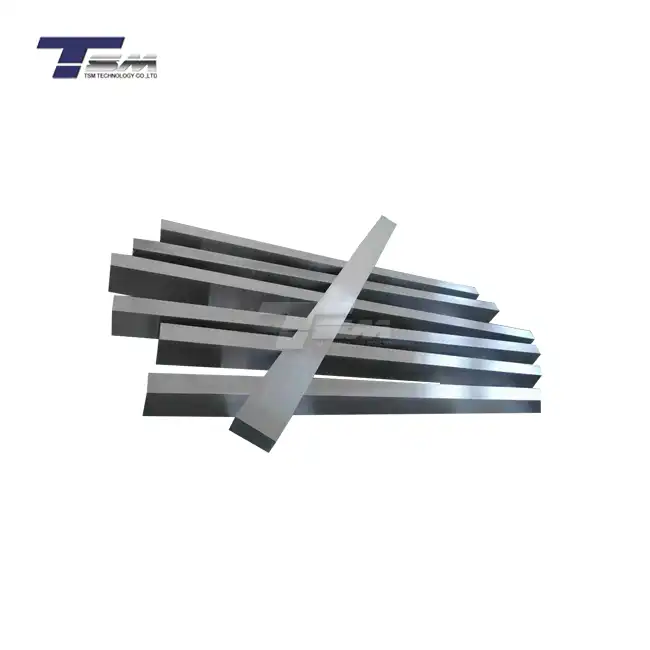

It takes expert knowledge and close attention to detail to keep your expensive nickel-copper alloy purchase safe during transit. The Monel 401 bar is one of the most corrosion-resistant materials you can use in marine, chemical processing, and aircraft uses. However, if you don't package and ship it properly, the surface could become damaged. Damage to the surface, like scratches, holes, and contamination, can seriously affect how well the material works and how it is used in later steps of the manufacturing process. Knowing how to avoid these problems will protect your investment and make sure that the best qualities of the materials make it to the production floor in one piece.

Understanding Surface Damage Risks in Packaging and Shipping Monel 401 Bars

One of the biggest problems that buying teams that deal with high-performance metals have to deal with is damage to the surfaces during transport. Nickel-copper alloys are especially vulnerable to certain kinds of damage that can change their special qualities because of the way they are made.

Common Types of Surface Damage

During travel and treatment, materials break down in a number of different ways. When bars move and touch rough surfaces or each other, they can leave mechanical scratches. These scratches can turn into tiny channels that can start rusting processes. Dropping or crashing during loading can cause impact dents, and foreign materials can change the surface chemistry and make it harder to do other processing processes.

Environmental contact is another type of risk that people who work in buying need to think about. When moisture gets inside, it can start oxidation processes, especially when it mixes with salt air or chemical vapors. Changes in temperature during long shipping times may lead to condensation, which makes the conditions perfect for surface wear.

Impact on Material Properties and Application Performance

The performance traits that make these metals, including Monel 401 bar, useful for tough jobs are directly linked to how well the surface is maintained. Quality control data from TSM Technology shows that even small harm to the surface can lower resistance to corrosion by up to 15% in naval settings. According to manufacturing experts, scratched surfaces need more machining processes, which raises costs and lengthens wait times.

The effects go beyond instant processing issues and affect the long-term dependability of applications. Damaged surfaces create stress concentration spots that can make spinning equipment like propellers and pump shafts less resistant to wear. When surface pollution gets in the way of an alloy's natural passivation properties, it's especially bad for chemical processing uses.

Financial Consequences of Inadequate Protection

Damage to the surface has a big effect on the economy and makes it hard to buy things all along the supply chain. Rejected exports mess up production plans and force companies to buy things quickly at higher prices. Industry studies of aerospace and marine makers show that material waste from damaged rejections usually makes up 2 to 8 percent of the total shipment value.

Best Practices for Packaging Monel 401 Bars to Prevent Damage

To make security plans that work, you need to know exactly how nickel-copper metals can be broken and then use solutions that are tailored to each risk factor. Modern ways of packaging mix old-fashioned ways of keeping things safe with new materials made just for high-value metal items.

Protective Coating and Wrapping Systems

Modern packing methods use multiple layers of protection that are specifically designed to work with high-performance metals. The first layer of touch is usually made up of special plastic films or paper wraps that have been treated with corrosion-resistant chemicals. These materials keep the bars from touching each other directly and keep wetness out, which is important for keeping the surface's structure.

Cushioning materials that reduce mechanical shocks during handling are often used in secondary wrapping. Metal goods with foam padding systems spread contact forces over larger surface areas, making it less likely that dent will form. Some makers use protective sleeves that are custom-formed to fit standard bar sizes. This way, the security stays the same no matter how the bars are handled.

Container Selection and Internal Organization

The right choice of container strikes a balance between the need for safety and the need for efficient shipping and low costs. Wooden crates are great for protecting big packages and have fixing holes for security systems. Metal containers are better at keeping things inside safe, but they need to be carefully padded on the inside so that Monel 401 bars don't touch the walls of the container.

Strategic spacing and locking methods in internal organization systems stop damage caused by movement. The packaging experts at TSM Technology say that there should be a minimum distance between each bar and that all empty spaces should be filled with enough cushioning material. Bundle arrangements need to take weight distribution into account so that materials that are lower on the stack don't get crushed.

Environmental Protection Measures

Controlling moisture is an important part of making sure that packaging methods for corrosion-resistant metals work well. Desiccant packets that are the right size for the container space help keep the humidity low during long shipping times. Vapor barrier sheets shut off areas so that outside wetness can't get in while still letting you control the humidity inside.

Keeping an eye on the temperature is especially important for packages that go through multiple climate zones or go through yearly changes. Insulation systems help keep temperatures from changing too much, which could lead to condensation, and thermal barriers keep things from getting too hot or too cold while they are being stored or moved.

Shipping Strategies to Protect Monel 401 Bars from Damage

The type of transportation has a big effect on the amount of security needed and the risks that packaging systems have to deal with. Each shipping method has its own problems that buying teams need to plan for and solve by working with suppliers to coordinate.

Transportation Mode Optimization

Ocean freight is usually the cheapest way to move a lot of things, but the materials are subject to longer travel times and the harsh conditions of the ocean. Shipping things in containers is a great way to protect them from the weather and use standard wrapping methods. Because the times are longer, better moisture control methods and strong packing systems that can keep things safe for weeks or months are needed.

Air freight allows for fast arrival with less damage to the environment, but it has strict weight and size limits that limit the types of packing that can be used. Because of how much stuff has to be handled during air transport, it needs better impact protection, and changes in pressure during flight can affect systems that seal packages. Because of the high cost, air freight is usually only used for pressing sales or specialty things with a high value.

Loading and Handling Protocols

Professional handling methods lower the risk of mechanical damage to Monel 401 bar during the most vulnerable parts of travel. When you use the right lifting methods and tools, you can avoid dropping things, which can cause damage. Forklift drivers need to be trained in how to properly handle packaged metal goods so that they don't damage the protected wrapping or put too much pressure on the packing systems.

When stacking things, you need to think about how the weight will be distributed and how stable the packages will be during travel. The compression strength of the bottom packages must be high enough to support the upper layers, and the defense of the top packages against moving during movement is needed. Securing systems, such as straps, blocking, and support, keep packages from moving, which could cause damage in case they crash.

Environmental Control During Transit

When packages are going through places with big changes in temperature or humidity, climate control becomes very important. Refrigerated packages keep the temperature and humidity inside very precisely, but they cost a lot more to move. Passive temperature control systems that use insulation and desiccants are cheaper ways to protect the environment to a mild degree.

Monitoring tools let you keep an eye on the surroundings at all times during the shipping process. Temperature and humidity loggers keep records of the conditions during transport and allow quick responses to changes in the environment that could threaten the security of the goods. Some more advanced systems have alerts that let both shippers and receivers know about situations that could be harmful.

Comparing Monel 401 Bar Packaging and Shipping with Other Alloy Bars

Learning about the unique needs of various alloy groups helps procurement pros come up with the best security plans while keeping costs low. Nickel-copper alloys are different from more common materials like stainless steel or carbon steel because they have their own problems that need to be solved.

Material-Specific Protection Requirements

The alloys' ability to prevent corrosion makes them valuable, but it also makes packing difficult because of how the surface reacts with chemicals and how sensitive it is to the environment. Nickel-copper metals need to be constantly protected from contamination sources that could mess up their natural processes for resisting corrosion. This is different from stainless steel, which forms protective oxide layers.

For precise uses, the surface finish of Monel 401 bar needs more security than for structural materials, where small surface differences are okay. Turned and polished surfaces of Monel 401 bar are widespread in aircraft and marine uses. To keep the quality of the surface of Monel 401 bar throughout the supply chain, they need to be handled in a certain way.

Cost-Benefit Analysis of Enhanced Protection

Investing in better packing methods usually costs between 2 and 5 percent of the total value of the goods, but it can save 10 to 20 percent in rejections due to damage. Aerospace companies say that better packaging cuts down on review time and repair costs while making production schedules more reliable. Depending on the number of orders and the history of damage, better packing usually pays for itself in three to six months.

When replacements take 8 to 12 weeks, custom sizes and materials with special tolerances make premium security especially cost-effective. Emergency sourcing costs for damaged luxury items can be more than 200% of the normal price. This means that taking precautions with packing is a very good way to save money.

How to Choose a Reliable Monel 401 Bar Supplier for Packaging and Shipping Excellence

Along with standard factors like material quality and price, criteria for choosing a supplier must include the ability to package goods. The best providers show that they fully understand the problems that come up with shipping and spend money on packaging systems that keep customer investments safe throughout the supply chain.

Certification and Quality Standards Evaluation

Industry licenses give you an objective way to see how skilled and dedicated a seller is to quality management. ASTM B164 compliance makes sure that the dimensions are correct and that the mechanical properties meet the standards, and ISO 9001 approval shows that the quality management is done in a planned way. Extra licenses, like AS9100 for aircraft uses or NORSOK for marine settings, show that you have specialized knowledge in niche markets that are very picky.

Material tracking paperwork is especially important for mission-critical uses that need to see the whole supply chain. Mill test certificates and SGS test reports confirm the chemical make-up and mechanical qualities, and heat number tracking lets you keep a close eye on each lot as it is made and shipped.

Packaging Infrastructure Assessment

Leading providers put money into special packaging sites that have materials and tools made just for high-value metal goods like Monel 401 bar. TSM Technology has special packaging lines inside their 3,200㎡ production center. This lets them do both manufacturing and packaging at the same time, which cuts down on the risks of damage during handling.

By working with expert packaging suppliers, suppliers of packing materials show their dedication to providing the best safety. For custom packaging solutions to work, alloy makers and packing experts often need to work together to create the best security systems for each application and shipping need.

Service Integration and Support Capabilities

Full range of services speeds up the buying process and makes sure that security standards are the same for all orders, no matter how big or small they are. Custom sizing lets sellers get the most out of the materials they have while lowering the amount of supplies customers need. TSM Technology's free sampling tools help with material qualification processes, and their special tolerance services (±0.05mm) make precision uses possible.

Customers can get help from technical support services to get the best packing for their needs and shipping needs. Experienced sellers can help you choose the best way to package your items, ship them, and handle them so that they are safest and costs are kept to a minimum.

Conclusion

To protect Monel 401 bars while they are being packed and shipped, you need to know a lot about how materials can be damaged, use systematic packing methods, and be very picky about which suppliers you work with. Putting money into good safety systems pays off in the form of fewer damage claims, more efficient production, and better material performance in important situations. To be successful, you need to understand that the integrity of the surface has a direct effect on both the instant processing processes and the long-term reliability of the application. This means that excellent packing is necessary for these valuable materials and not a choice.

FAQ

1. What packaging materials are best suited for preventing corrosion on Monel 401 bars?

When used together, anti-corrosion wraps and moisture shield films offer the best defense against the elements. Specialized plastic films that have been treated with rust inhibitors act as shields to keep things safe, and desiccant packets keep the humidity level inside sealed packages under control. For the best results, TSM Technology suggests multi-layer wrapping systems that cover the surface directly and keep the world out.

2. How does improper packaging affect the mechanical properties of Monel 401 bars?

Damage to the surface from bad packing can lower the tensile strength by causing stress concentration spots, and contamination and scratches can lower the resistance to corrosion. Impact damage can cause work hardening, which can make it harder to machine later on, and chemical pollution can change the surface chemistry and make it harder to weld or shape.

3. Can Monel 401 bars be shipped to marine environments without special precautions?

Marine settings need extra security because the salt air and high humidity speed up the rusting process. To keep materials intact while they're being shipped to coastal or offshore areas, they need extra moisture barriers, longer desiccant protection, and sealed packing systems.

Partner with TSM Technology for Superior Monel 401 Bar Protection

TSM Technology has been making high-quality nickel-copper alloys for 14 years and also knows how to package them perfectly, so your investments will come in perfect shape. Our integrated production plant has 8 production lines and more than 100 tools. This lets us control quality from melting to packaging, and our 300-ton-per-month capacity makes sure that we can meet the needs of difficult uses. Get in touch with our expert team at info@tsmnialloy.com to talk about your Monel 401 bar manufacturer needs and find out how our advanced packing systems can keep your valuable materials safe throughout the supply chain.

References

1. American Society for Testing and Materials. "Standard Specification for Nickel-Copper Alloy Rod and Bar." ASTM International Publication B164-18.

2. Maritime Engineering Research Institute. "Surface Integrity Effects on Corrosion Resistance in Marine Alloys." Journal of Marine Materials Science, Vol. 45, 2023.

3. Aerospace Materials Handbook Committee. "Packaging Standards for High-Performance Alloys in Critical Applications." Society of Aerospace Engineers Technical Report, 2022.

4. Industrial Packaging Association. "Best Practices for Metal Product Transportation and Storage." Professional Packaging Guidelines, Third Edition, 2023.

5. National Association of Corrosion Engineers. "Environmental Protection Requirements for Nickel-Based Alloys." NACE International Standard Practice, 2022.

6. International Organization for Standardization. "Quality Management Systems for Aerospace and Defense Industries." ISO 9100 Series Implementation Guide, 2023.

Learn about our latest products and discounts through SMS or email